CE ISO 100-400kg/h Dough Forming Single Screw Extruder Machine Green Food Equipment

Corn puff snacks food machine is a new type of extruding food machine studied and developed by ourselves on the basis of learning from advanced technology in the world so that its technical performance and quality of products both reach to the most advanced in the world. This line will finish mixing, extruding, cutting, spraying, and producing in onepass operation automatically. This has features of lots of types, flexible collocation, extensive applied materials, various products and easy operation. As a professional Single Screw Extruder Machine manufacturer, we have been in this field for 15 years. Our Single Screw Extruder Machine design good manufacturing process. Single Screw Extruder Machine can take Corn, potato grains and others as raw materials, to make pellet snacks,2D pellet, 3D pellet, and special dietary pasta.

CE ISO 100-400kg/h Dough Forming Single Screw Extruder Machine Green Food Equipment Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Condition | New |

| Function | Multifunction |

| Automation | Fully Automatic |

| Certification | CE BV ISO 9001 |

| Warranty | 1 YEAR |

CE ISO 100-400kg/h Dough Forming Single Screw Extruder Machine Green Food Equipment Detail Introduction :

Snack food is made by potato starch, corn starch, corn flour, wheat flour, cassava starch and other raw materials. The single screw extruder food is kneaded under high pressure and cooked by the frictional heat produced between the barrel and screw. After drying and frying, flavoring with the flavor powder can get delicious snacks food. The single screw extruder has more extrusion capacity than ordinary extruder, and can also deal with all kinds of raw materials of granular food. Single screw extruder’s versatile features have made it increasingly popular with customers who want more capacity.

HOW DOES SNACK FOOD EXTRUDER MACHINE WORK?

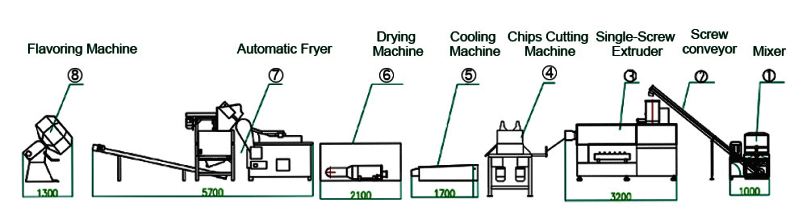

| Function Of Each Part Of Dough Forming Single Screw Extruder Machine Green Food Equipment | ||

| NO. | NAME | FUNCTION AND CHARACTERISTICS |

| 1 | MIXER | Mixing various flour ingredients and water evenly. |

| 2 | SCREW CONVEYOR | Screw conveyor can not only convey on the level but also by any angel these materials can be conveyed in the stainless steel roller without leaking, dust pollution; meanwhile it can send the self-mixer to the feeding machine or the conditioner and directly send the discharge hole of the inflating extruder. |

| 3 | SINGLE SCREW EXTRUDER WITH COOLING SYSTEM | Extruding the mixture into different shapes(this machine uses different die can produce different shape product).And the main extruder adopts frequency speed controlling with high automation and stable per-formation. The screws are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer. |

| 4 | CHIPS CUTTING MACHINE | Be used to punch the product and shape the product. |

| 5 | COOLING CONVEYOR | Used to carry expanded food to the next device. |

| 6 | VIBRATE COOLING CONVEYOR | Be used to convey& cooling pellet sheets before go to Cutting. |

| 7 | HOISTER | Be used to transport the products from vibrate cooling conveyor. |

| 8 | LOWER TEMPRETURE DRYING MACHINE | The conveyor belt and the inner guard plate on the top of the oven are made of 304 stainless steel. |

| 9 | COOLING CONVEYOR | Be used to cool products. |

TECHNICAL PARAMETERS OF SINGLE SCREW EXTRUDER MACHINE

| Dough Forming Single Screw Extruder Machine Green Food Equipment Techinical Parameters | |||

| Model | SNP-1 | SNP-2 | SNP-3 |

| Installed Power | 30kw | 45kw | 50kw |

| Power Consumption | 120kw | 164kw | 394kw |

| Output | 100kg/h | 250-300kg/h | 400-600kg/h |

| Size (L*W*H) | 27000x2000x2000mm | 30000×2000×2000mm | 43000*2000*3200mm |

DETAIL OF SNACK FOOD PRODUCTION LINE FOR SALE

CE ISO 100-400kg/h Dough Forming Single Screw Extruder Machine Green Food Equipment

SNACK FOOD PRODUCTION LINE SPECIFICATIONS :

| Date Of Dough Forming Single Screw Extruder Machine Green Food Equipment | |

| Brand Name | Loyal |

| Material | Adopt 304 stainless steel. |

| Control system | Adopts advanced computer touch screen, plc control |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C, D/P, T/T, Western Union |

| Delivery Detail | 30 days--35 days |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification: | CE, ISO9001, SGS, BV |

ADVANTAGES FOR SNACK PELLET EXTRUSION PROCESS LINES

CE ISO 100-400kg/h Dough Forming Single Screw Extruder Machine Green Food Equipment

| Why Do You Choose Loyal Dough Forming Single Screw Extruder Machine Green Food Equipment? | |

| 1 | The production line can make any type snack food of starch-based raw material. |

| 2 | LPG/Natural Gas/Electric/Diesel can be opted according to customer’s requirements. |

| 3 | Output ranging from 80kg/h to 400 kg/h of dried pellets. |

| 4 | Each machine can adjust the temperature |

| 5 | Adopts advanced computer touch screen, plc control, variable frequency speed control and automatic deviation. |

| 6 | You can change recipes and molds to make new products and new product shapes. |

| 7 | Power seeping protector is equipped. |

| 8 | An automatic temp command device is equipped, when it is anomaly temp, the protect will certainly operate and give an alarm |

| 9 | The temperature can be controlled to make the particle size even. |

ADVANTAGES OF FRYING MACHINE TO MAKE SNACK FOOD

| Why Do You Choose Loyal Dough Forming Single Screw Extruder Machine Green Food Equipment Frying Machine? | |

| NO. | ADVANTAGES OF FRYING MACHINE |

| 1 | The frying machine has electric heating, diesel heating, gas heating and other ways, and is smokeless. |

| 2 | This frying machine adopts the international most advanced oil and water mixed frying process, completely changed the original oil and water mixed frying process, fundamentally solves the shortcomings of the traditional oil pan. |

| 3 | It can be used for frying all kinds of snack food at the same time without affecting each other. |

| 4 | In the process of frying machine can automatically control the temperature, prolong the service life of frying oil. |

| 5 | Snack food can be taken from heating reservoir in the middle of the process, which can control the temperature of the upper and lower reservoir. |

| 6 | The frying machine can effectively alleviate the degree of oxidation of frying oil, and inhibit acid medium and automatic filter residual in the process of frying. |

FINISHED PRODUCTS PICTURES:

Raw materials: corn starch, cassava starch, wheat flour, corn flour and so on.

Application: 3d pellet snacks, 2d pellet snacks, special dietary pasta, pellet chips food, etc,. Snack food machine can be used to produce different shapes of pellets by adjusting the molds of extruder.

After frying, the snack food will swell, and some seasoning powder will make them even more crispy. Snack food machine technology is unique, which has reasonable configuration, high degree of automation and stable performance.

Dough Forming Single Screw Extruder Machine Green Food Equipmen Customer Case

| Customer cases for snacks making machine for factory in 2021 | |

| 1 | 1t/h cost of snacks making machine sold in russia customer’s factory |

| 2 | 1t/h industrial snack maker machine price for factory for sale in puerto rico puffy snack plant agent |

| 3 | 1t/h industrial snack maker machine price for sale in bolivia customer’s factory |

| 4 | Senegal 1t/h industrial fully automatic industrial snack maker machine |

| 5 | 1t/h snacks making machine price for sale in côte d'ivoire |

| 6 | China 300t/year industrial fully automatic snacks making machine price |

| Customer case of snack food making machine at 2021 | |

| 7 | 1t/h microwave drying equipment for factory in uzbekistan puffy snack machinery agent |

| 8 | 1000kg/h snack maker machine for sale in senegal customer’s factory |

| 9 | Mozambique 1t/h fully automatic snacks making machine price |

| 10 | Bangladesh 2t/h fully automatic snacks making machine price |

| Dealed customer have technology of corn puff extruder machine at 2021 | |

| 11 | 1t/h thai snack food making machine for factory |

| 12 | Uzbekistan 1t/h fully automatic corn puff extruder machine |

| 13 | Usa 1t/h corn puff extruder machine |

| 14 | 800kg/h industrial snacks making machine for sale in nigeria customer agent |