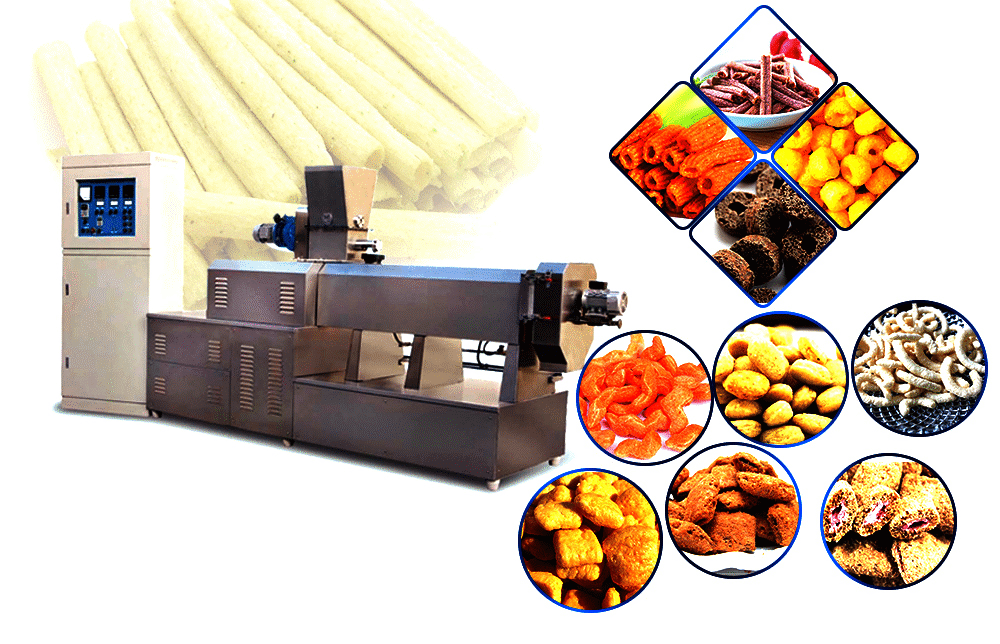

Automatic Twin Screw Extruder Machine Production Line snack extruder machine corn puff extruder machine

Corn puff snacks food machine is a new type of extruding food machine studied and developed by ourselves on the basis of learning from advanced technology in the world so that its technical performance and quality of products both reach to the most advanced in the world. This line will finish mixing, extruding, cutting, spraying, and producing in onepass operation automatically. This has features of lots of types, flexible collocation, extensive applied materials, various products and easy operation.As a professional manufacturer of corn puffed snack production line, we have been in the field of puffed extruder machine for many years. We are the supplier of corn puff making machine, our corn puffed extruder machine design good manufacturing process.

Automatic Twin Screw Extruder Machine Production Line snack extruder machine corn puff extruder machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 10-25 working days. |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Automatic Twin Screw Extruder Machine Production Line snack extruder machine corn puff extruder machine Detail Introduction :

Product Description of Puff Snack Production Line

As a professional manufacturer of corn puffed snack production line, we have been in the field of puffed extruder machine for many years. We are the supplier of corn puff making machine, our corn puffed extruder machine design good manufacturing process. corn puff making machine can take corn, rice , wheat, oat, grains, potato flour, and others as raw materials, to make the cheese balls, corn curls, corn sticks, coco pops, cereal.

The Automatic Twin Screw Extruder Machine Production Line incorporates advanced technology to meet the growing demands of the snack food industry. Featuring a robust twin screw extrusion system, this machine ensures precise control over the cooking, mixing, and shaping processes, resulting in high-quality snack products with uniform textures and flavors. Its automated operation minimizes manual intervention, leading to increased production rates and reduced labor costs.

The Automatic Twin Screw Extruder Machine Production Line is a state-of-the-art solution designed for the efficient and scalable production of a wide range of extruded snacks. This includes popular snack items such as corn puffs, cereal grains, pet food, and more. Utilizing advanced twin screw extrusion technology, this production line offers unparalleled precision, versatility, and quality control in snack manufacturing.

Product Introduction

At the heart of this production line is the twin screw extruder machine, renowned for its capability to handle a variety of raw materials with varying levels of moisture content, viscosity, and texture. This adaptability allows for the production of a broad spectrum of snack products, from light and airy corn puffs to dense and crunchy cereal bars. The automatic control system ensures consistent product quality and efficient production processes, making it an ideal solution for manufacturers looking to scale up their operations or diversify their product offerings.

Product Advantages

Versatility: The twin screw design provides exceptional control over the cooking process, allowing for the creation of snacks with varied textures, shapes, and sizes. This versatility enables manufacturers to quickly adapt to changing market trends and consumer preferences.

High Efficiency: Engineered for continuous operation, the production line significantly reduces downtime and increases output, ensuring high productivity levels. The automation of key processes, from feeding to extrusion and cutting, minimizes the need for manual intervention, further enhancing operational efficiency.

Consistent Quality: Precision control over processing parameters such as temperature, pressure, and screw speed ensures that each product batch meets strict quality standards. This consistency is crucial for maintaining brand reputation and customer satisfaction.

Cost-Effectiveness: By optimizing raw material usage and energy consumption, the production line offers a cost-effective solution for snack manufacturing. The durability and low maintenance requirements of the twin screw extruder also contribute to reduced operational costs over time.

Ease of Use and Maintenance: Designed with the user in mind, the production line features an intuitive control system and easy access to key components, simplifying both operation and maintenance. Quick-change mechanisms for dies and screws allow for rapid product changeovers, maximizing production flexibility.

Safety and Hygiene: Constructed with food-grade materials and designed for easy cleaning, the production line meets the highest standards of food safety and hygiene. The enclosed design of the extruder also ensures a safe working environment for operators.

The Automatic Twin Screw Extruder Machine Production Line represents a comprehensive solution for the production of extruded snacks. Its combination of efficiency, versatility, and quality control makes it an invaluable asset for food manufacturers aiming to innovate and expand their snack product lines.

Puff Snack Production Line

| Information For Automatic Twin Screw Extruder Machine Production Line snack extruder machine corn puff extruder machine | ||

| 1 | Raw material | Corn, rice, wheat, oat, barley powder,etc. |

| 2 | Basic Recipe | Grist powder; sugar; coco; cheese; water |

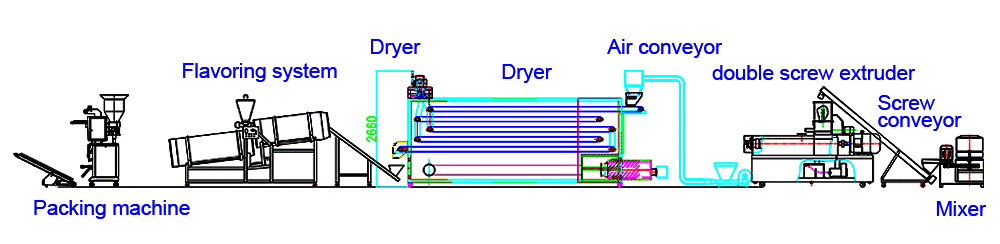

| 3 | Puffed Snack Production Line Involved | Mixer; Screw elevator; twin screw puffed extruder; Air conveyor; Roller dryer; |

| Tablet machine; Air conveyor; Dryer; Hoister; Vibrator; Hot air dryer; | ||

| Flavoring system; Dryer with cooler. | ||

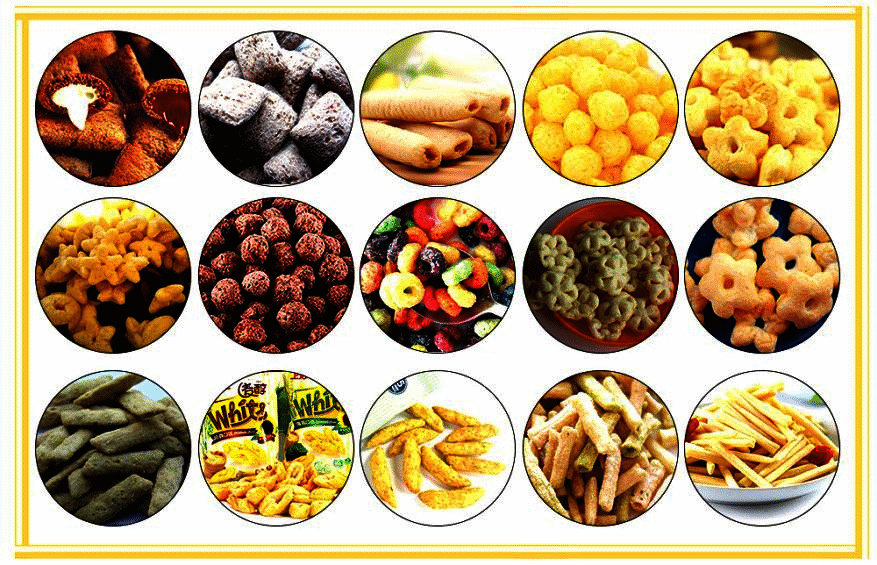

| 4 | Final products | Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower |

| and heart shape by adjusting the mould in the puffed extruder machine ; corn flakes; cereal snacks | ||

| 5 | Puffed Extruder Machine Material | Stainless steel 304 or as customer’s request |

Full automatic puffed snacks making machine is a new type of puffed extruder machine studied and developed by ourselves on the basis of learning from advanced technology in the world so that its technical performance and quality of products both reach to the most advanced in the world. This corn puffed snack making line will finish mixing, extruding, cutting, spraying, and producing in one pass operation automatically. The corn puffed snack line has features of lots of types, flexible collocation, extensive applied materials, various products and easy operation.

Technical Parameters For Puff Snacks Making Machine

| Data Of Automatic Twin Screw Extruder Machine Production Line snack extruder machine corn puff extruder machine | ||||

| Model | Installed Power | Power Consumption | Output | Size (L*W*H) |

| LY65 | 84kw | 59kw | 120-150kg/h | 21000x1200x2200mm |

| LY70 | 132kw | 92kw | 200-250kg/h | 23000x1500x2200mm |

| LY75 | 186kw | 139.5kw | 400-500kg/h | 24000x2000x2800mm |

| LY85 | 239kw | 167kw | 300-500kg/h | 28000x3500x4300mm |

Flow Chart of corn puffed snack production line

Mixer-- Twin-screw puffed extruder machine -- Air conveyor-- Multi-layer dryer--Hoister with flavoring part--Oil sprayer-- Single roller flavoring machine

Why Choose Puffed Extruder Machine

| Advantage Of Automatic Twin Screw Extruder Machine Production Line snack extruder machine corn puff extruder machine | |

| 1 | The body of twin screw puffed extruder machine plate and parts contacting food are all stainless steel. |

| 2 | All the brands of motors, inverters, and electrical elements can be adjusted as clients requirements. |

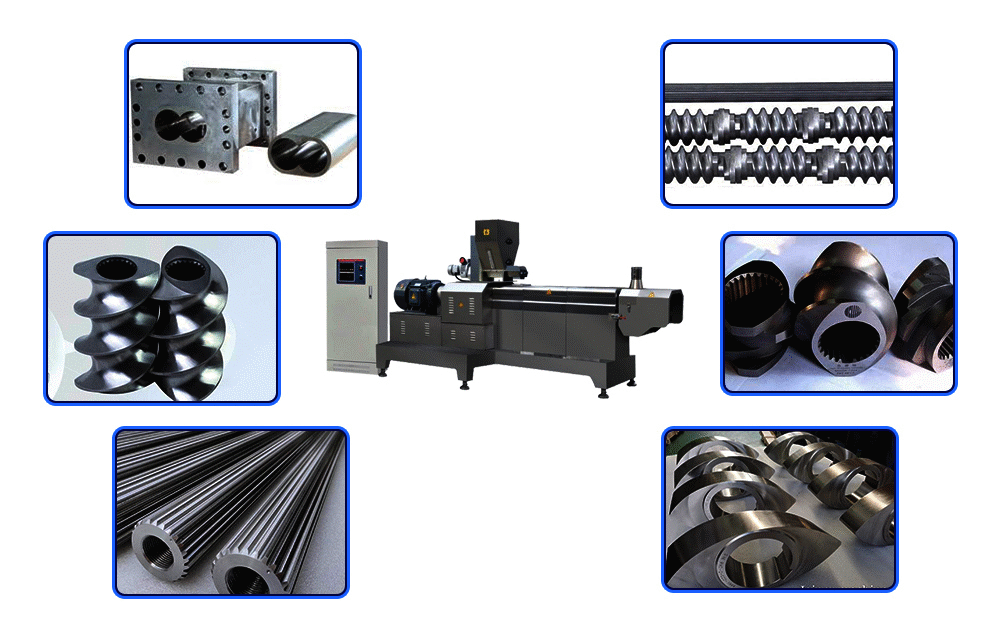

| 3 | With adopting the latest Italy design concept to do proper improvement for the structure of screw and barrel to make sure that twin screw extruder machine won't grind inside the barrel. This will not only extend their use life, and also avoid the grind iron scrap mixing into the material. |

| 4 | Unique design of the diversion-cone enables the uniform discharging, and pressure equalizing for the discharge point of the die. |

| 5 | The rational barrel and screw cooling structure and effective heating unit assure the accuracy of temperature control. |

Puffed Extruder Machine Photos of Puffed Snacks Production Line

| Information For Automatic Twin Screw Extruder Machine Production Line snack extruder machine corn puff extruder machine | |

| 1 | Direct transmission between motor and gear box, reducing energy consumption. |

| 2 | Feeding, main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. |

| 3 | Screw of puffed extruder machine is made of alloy steel with long life. Segmental assembled screws are applied to more kinds of materials and products. |

| 4 | Automatic lubrication system can lower down power consumption and prolong the life. |

| 5 | Twin Screw Extruder Machine feed equal materials forcibly. |

| 6 | Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly. |

The Application Of Corn Puff Making Machine

The raw materials of corn puffed snack making machine can be corn, rice, wheat, oat, rye, grains, potato flour, coco pops, cereal, etc. The color of the raw materials is different, so the products of this puffed extruder machine can be in multiple colors. But the raw material must be powdery.

Puffed extruder machine can produce cheese balls, corn curls, corn sticks. And the product shapes produced by this puffed snack production line can also be of many types: kurkure, pellets, balls, sticks shape, pillows, animals, stars, rings shape, Fried peanut shape, etc. Puff snacks making machine, corn snacks food making machine, snacks food processing line will all use this line with puffed extruder machine.

Packaging and Delivery

| Information for puffy snacks machinery shipping | |

| Packaging | With Wrapping film and in wooden case, or according to the customer needs. |

| Delivery Time | 10-15 Working days. |

| Shipping Type | By sea, railway, etc. |

Our Service

We provide Professional After sale service:

1.One year warranty for the machines.

2. Overseas installation and train the first-line operators.

3. For any questions, professional technicians will solve for you timely.

4. Training workers for the production

5. Provide basic formula.

Customer Cases For Automatic Twin Screw Extruder Machine Production Line Snack Extruder Machine Corn Puff Extruder Machine Snacks Making Machine For Factory In 2021

| Customer cases for snacks making machine for factory in 2021 | |

| 1 | 1t/h cost of snacks making machine sold in russia customer’s factory |

| 2 | 1t/h industrial snack maker machine price for factory for sale in puerto rico puffy snack plant agent |

| 3 | 1t/h industrial snack maker machine price for sale in bolivia customer’s factory |

| 4 | Senegal 1t/h industrial fully automatic industrial snack maker machine |

| 5 | 1t/h snacks making machine price for sale in côte d'ivoire |

| 6 | China 300t/year industrial fully automatic snacks making machine price |

| Customer case of snack food making machine at 2021 | |

| 7 | 1t/h microwave drying equipment for factory in uzbekistan puffy snack machinery agent |

| 8 | 1000kg/h snack maker machine for sale in senegal customer’s factory |

| 9 | Mozambique 1t/h fully automatic snacks making machine price |

| 10 | Bangladesh 2t/h fully automatic snacks making machine price |

| Dealed customer have technology of corn puff extruder machine at 2021 | |

| 11 | 1t/h thai snack food making machine for factory |

| 12 | Uzbekistan 1t/h fully automatic corn puff extruder machine |

| 13 | Usa 1t/h corn puff extruder machine |

| 14 | 800kg/h industrial snacks making machine for sale in nigeria customer agent |