Loyal is a manufacturer of baby food nutritional powder production lines. The company has dozens of technical engineers with rich experience in designing and manufacturing nutritional powder production lines. Loyal owns a number of project technology patents related to baby food production, and can provide you with the most detailed baby food manufacturing formulas, such as oatmeal porridge recipe, baby food powder formula, etc. The products produced by the baby food production line include oatmeal porridge, oat bran porridge, instant porridge and so on.

Loyal can also provide you with CAD design drawings of various production lines, such as CAD drawings of nutritional powder baby food processing production line, CAD drawings of extruded rice powder nutritional baby food processing line. Loyal helps you grow the baby food manufacturing industry better while saving the cost of your baby food production line.

Baby Food Production Line Recommend Products

Baby Food Production Line Video

Baby Food Production Line Detail Introduction

With years of experience in nutrition powder machine manufacturing, loyal can develop and design superior and reliable nutritional powder machine equipment with high quality that meets different needs of customers, providing them with an excellent baby powder food production line.

Loyal is a professional team. Our skilled nutritional powder production line designers, responsible and reliable nutritional powder machine salespeople, first-class nutritional powder equipment and cutting-edge nutritional manufacturing production technologies have helped us win long-term customers. Perfect nutritional powder production plan and sophisticated nutritional powder manufacturing equipment help every customer grow faster in baby food and related industries.

In terms of the price of baby powder food production line, Loyal's products are also the most cost-effective. Loyal considers to save you the cost of nutritional powder machine while bringing you high profits. At the same time, we provide the most thoughtful nutritional powder machine equipment service, you don't need to worry about anything.

We own the whole baby food processing line, we have learned from overseas advanced technology and developed the whole set of machines for baby food.

Loyal's nutritional powder production line changes the traditional way of steaming raw materials, instead pressing these grains under high temperature and pressure. All the grains are extruded within 5 seconds. With the aid of the nutritional powder production and processing line, the starch in the denatured raw grain is conducive to absorption and has higher nutrition than the traditional nutritional manufacturing process. The food produced by the nutritional powder machine is specially designed for babies.

Baby Food Production Process Flow Chart

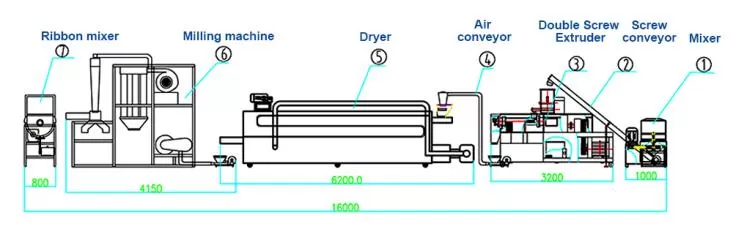

Mixer → screw conveyor → twin-screw extruder → air conveyor → dryer → cooling conveyor → air compressor → crushing machine

Machine List Of Baby Powder Making Machine | |||||

Production Line | Capacity | Dimension | Voltage | Power | Weight |

Mixer | 600-800Kg/H | 650*550*900mm | 220V-3 | 0.75Kw | 100Kg |

Screw Conveyor | 1000Kg/H | 2000*650*1300mm | 220V-3/380V-3 | 0.75Kw | 400Kg |

Twin-Screw Extruder | 100-150kg/H | 2000*2000*1700mm | 380V/50Hz | 44.0Kw | 300Kg |

Seven-Layer Oven | 300Kg/H | 1200*1200*1400mm | 380V/50Hz | 1.5Kw | 100Kg |

Air Conveyer | 1000Kg/H | 1900x800x1000mm | 380V/50Hz | 0.75Kw | 400Kg |

Miller Machine | 300Kg/H | 1500*700*1600mm | 380V/50Hz | 1.5Kw | 200Kg |

Mixer: In the nutritional powder production line, the mixer is used to mix all the raw materials and add a certain amount of water (dry powder mixer does not need to add water) to make the ingredients uniform.

Screw Conveyor: In the nutritional powder production line, the screw conveyor is used to convey the material to the extruder.

Twin-screw extruder: In the nutritional powder production line, the twin-screw extruder is used to extrude and shape nutritional powder products, which is a very critical step in nutritional powder production.

Air Conveyor: In the nutritional powder production line, the air conveyor transports the small nutritional powder product to the dryer for further processing.

Dryer: In the nutritional powder production line, the dryer is used to remove the moisture from the nutritional powder product and make it dry.

Grinders: In the nutritional powder production line, grinders are used to grind particles into powder and remove dust.

Composition of baby food manufactured by nutritional powder production line:

Rice, brown rice, millet, corn, white sesame, black sesame, black bean, soybean, lotus seed, yam, red bean, buckwheat, lily, red date, etc.

Components of the Baby Food Production Line

Ingredient Batching System: Precisely measures and mixes ingredients to ensure consistent nutritional content.

Blending and Mixing Equipment: Combines ingredients uniformly without degrading their quality.

Cooking and Sterilization Systems: Utilizes pasteurization or other cooking methods to kill pathogens while preserving nutrients.

Homogenization: Breaks down particles to make the food easily digestible for babies.

Filling and Packaging Machinery: Ensures that the food is packaged in a sterile, safe environment, often in convenient, ready-to-eat portions.

More Description Of Loyal Nutritional Powder Production Line:

Loyal's baby powder food production line gains twin-screw extrusion technology developed by our company. The traditional baby food processing method has many disadvantages such as inefficiency, safety problem and small-scale production.

In the baby powder food production line, twin-screw extrusion technology makes up all these deficiencies, which means it can not only deal with grain materials, such as buckwheat, oats, etc. but also produce more nutritious and healthy foods that are good for your body.

Our baby nutritional powder machine equipment is highly efficient that can process and produce a lot of baby food in a very short time. Nutrition powder machine always saves you plenty of working time and manpower and improves working efficiency.

All the parts of our baby nutrition powder machine are made of food-grade stainless steel, which is very advanced with high quality. Loyal's principle is to make sure everything is in baby powder food production line with the food safety and health standards, especially the baby food produced by our nutritional powder machine equipment is healthy and safe. Baby can go ahead and enjoy their yummy food, it is also beneficial to their growth.

Loyal has obtained CE and many other certificates and is a gold supplier of Alibaba. Shandong Loyal Industrial Co.,Ltd. has a comprehensive manufacturing plan for infant nutrition powder production line. Provide all equipment of reliable nutritional powder production line for customers in nutritional powder food processing machinery and related industries.

Loyal can provide factory layout and nutritional powder production line equipment for nutritional powder production projects, which can be customized according to customer requirements. Everything we do is for customer satisfaction, which is our pursuit, and we hope to establish a long-term friendly partnership with our customers.

At present, Loyal's infant nutrition powder production line and other equipment are selling very well, and our products are very popular not only in China but also all over the world.

Buyers of our nutritional powder production line come from all over the world, such as Brazil, UK, Russia, Pakistan, etc. After using our nutritional powder machine, they are very satisfied and decide to establish a long-term partnership with us.

Feel free to contact Loyal if you need any equipment in your nutritional powder line. We look forward to reaching a friendly agreement with you to provide you with the best nutritional powder production equipment to achieve a win-win situation.

Baby food Production line: complete using guidance

Baby food is the main daily food for infants and young children, and its nutrition, safety and other aspects, as well as the production and processing process of nutritional powder, all require great attention. Let's take a look at the technology of baby food and baby food line processing.

1. Baby Food

Food is the top priority of the people, and food safety is the number one issue, especially baby food. It is crucial to prepare a balanced diet for babies, which must include fruits, vegetables, meats, etc. Do not feed your baby only one food to avoid the cumulative effect of food additives and nutritional imbalances. Fruits for babies can be squeezed into juice, vegetables and meat can be boiled into puree, and they can be easily fed to babies. We can provide you with formulas of various nutritious foods and nutrition porridge, such as oatmeal porridge, instant porridge, porridge cereal, etc., which are easy for your baby to digest and absorb. Therefore, you can use our baby nutrition powder production line equipment with confidence, or you can consult us about other baby nutrition powder machine, and we will explain to you.

2.National food safety standards for infants and young children

(1) The baby food produced by the baby food nutrition production line should meet the requirements of nutritional ingredients.

(2) The baby food produced by the baby food nutrition production line shall meet the food hygiene and quality requirements of production and operation.

(3) The baby food produced by the baby food nutrition production line shall have a complete inspection system and supervision procedure.

(4) The baby food produced by the baby food nutrition production line shall not contain pathogenic microorganisms, pollutants, heavy metals, pesticides and veterinary drug residues and other substances that are harmful to human health.

(5) The baby food produced by the baby food nutrition production line should not contain too many additives and preservatives that exceed the national standards of our country. In addition, the use of industrial materials in the production of baby food nutrition lines is prohibited.

(6) Common sense and feeding experience in the production of baby food nutrition production line tell us that the best baby food is homemade food with natural ingredients, because it does not contain any preservatives and additives. Safe for the baby, while providing adequate nutrition for the baby.

3. How Do You Choose Baby Food?

Infancy is not only a critical stage of growth and development, it is also the most vulnerable period. At this time, the baby's immunity is low and the body is weak. If he eats unlicensed and unhealthy food, the baby will suffer a lot, which is very detrimental to his growth. Therefore, parents must pay special attention to choosing healthy and safe food for their babies. Therefore, it is very important to use safe nutritional powder manufacturing machines.

Breastfeed your baby only at first, and normally, when your baby is 4 months old, he or she can eat some solid foods. This time, as a parent, you must pay more attention to the safety of the food you feed your baby every day. Dairy products are a common food for babies, but be sure to check the quality of the product before feeding. It is necessary to choose nutritional powder produced by a manufacturer with a high-quality nutritional powder production line.

When choosing a baby food, check the date of manufacture as well as the ingredients, nutrients and their proportions in the product. Safety permits play an important role when choosing baby food, and for imported food you need to check the product for the CIQ mark. Baby food made by the nutritional powder production line produced by loyal is rich in nutrients, especially oatmeal porridge, instant porridge, and baby food powder are very popular with children.

4. Introduction Of The Baby Food Production Line:

The baby powder food production line uses rice, corn, beans, and other grains as ingredients to produce a variety of baby foods, such as oatmeal porridge, instant porridge, and baby food powder after extruding, puffing, drying, crushing and mixing procedure. The baby powder food production line is very automatic and easy to operate, you just mix various grains, then the nutrition powder machine begins to work and process automatically without any power leaking. The whole procedure is energy-saving and hygienic, you can put more nutrients to get more healthy baby food.

Our baby powder food production line owns many advantages, its advanced technology makes it more prominent in the industry. The processed food is full of nutrition. A balanced diet is good to your baby’s growth and development, and it can be consumed for a long time and your baby will be stronger.

5.Benefits of Baby Food Production Line:

(1) The extruder of the nutritional powder production line adopts frequency conversion speed regulation, which has a high degree of automation and is very stable.

(2) The screw of the nutritional powder production line is made of alloy steel, which has been specially treated to withstand high pressure and is durable.

(3) The lubrication system of the twin-screw extruder of the nutritional powder production line ensures longer transmission tasks.

(4) The nutritional powder production line has an automatic temperature control system, which can directly check the temperature and is very accurate. The self-cleaning feature of the nutritional powder line saves you time as you don't need to disassemble it.

(5) The food production method of the nutritional powder production line is simpler and more cost-effective than the traditional baby food production method.

(6) The nutritional powder production line integrates stirring, cooking, pickling, fermentation, sterilization and packaging, without the need for a boiler, and the production process is simpler, more efficient and environmentally friendly.

(7) The main engine of the nutritional powder production line adopts domestic high-efficiency twin-screw extruding technology to meet the processing needs of different nutritional powders such as rice flour, corn flour or their mixtures.

6.Parts of Baby Food Production Line

Baby powder food production line consists of mixer, screw conveyor, twin-screw extruder, air conveyor, oven, crusher, packaging machine, etc. The extruder of the baby powder food production line is equipped with: a special cylindrical silo; a hopper feeder that vibrates while conveying the grain to the twin-screw extruder; extrusion and cutting units; a separate electrical panel.

7.Support Equipment of Baby Food Production Line

According to the customer's product, we will arrange the suitable nutritional powder production line design. Since the production requirements of a nutritional powder production line vary from customer to customer, loyal ensures that an appropriate and excellent processing program for infant nutritional food is developed. Due to economic growth and technological upgrades, nutritional powder manufacturers typically use highly automated production line configurations.

8.How Baby Food Production Line Works

Baby nutrition powder machine is used to produce baby food and some other instant flour products. When the nutritional powder production line is in operation, the ingredients need to be poured into the mixer, and then the mixed granules are put into the extruder, extruded into a certain shape, and then dried in the dryer, and finally the finished product is packaged.

9.Industries using Baby Food Production Line

The baby nutrition powder machine is specially designed for the processing of baby food, nutrition powder, rice flour, sesame, oatmeal, instant porridge and other foods. Nutrient powder machines can handle various ingredients by changing temperature, humidity and drying parameters. The ingredients can be a variety of flours and starches, pure or blends, such as rice, soybean, corn, oat, millet, wheat, sorghum, banana, tapioca, and potato. loyal does provide you with recipes, vitamins, minerals and other nutrients that can be added to meet different nutritional needs.

10.Types of Baby Food Production Line in the Market

According to the production output and food raw materials, the nutritional powder product line can be divided into small, medium and large production lines. The needs of customers are different, so the products produced by the nutritional powder machine have certain differences, so the baby food production lines are also different. But we can choose the most suitable nutritional powder production line for you according to your actual needs.

11.Baby Food Production Line Maintenance Process

The maintenance of the nutritional powder production line is an important part of the correct use of the nutritional powder machine. So you must pay more attention to the maintenance of the nutritional powder machine to reduce any failure, which is directly related to the safe operation, energy consumption and durability of the nutritional powder production line. Only need to focus on cleaning and safety inspection, three times before starting, during operation, and after completion. Check the performance of the operating mechanism, operating parts and protective devices of the nutritional powder production line, and properly clean the nutritional powder machine and all assembly parts. Another point is that the lubrication should be in place, and the loose parts in the nutritional powder machine should be tightened.

The classification and operation and maintenance of the nutritional powder machine are carried out according to the structure, use and environmental conditions of the equipment. According to the wear and aging laws of nutritional powder machine parts, similar parts are gathered together. Parts are then serviced to prevent deterioration and keep them clean to identify and eliminate safety hazards and prevent their premature failure. Therefore, the nutritional powder production line can still work normally.

12.How to Verify The Quality of Baby Food Production Line

Through the joint efforts of the loyal team, our baby nutrition powder machine has the most advanced machine parts. You don't need to worry about the quality of your nutritional powder production line, loyal is very reliable. Nutritional powder machines are very durable. loyal has always been committed to making the nutritional powder line stand the test of time, and after trying out our nutritional powder machine, you will find that it is worth the money.

13.The Validation Documents of Baby Food Production Line

We’ve got the CE, ISO9001 certificates. Our nutritional powder machine equipment is very trustworthy as all parts in touch with the food are made of non-toxic materials that have fully met the QS certificate requirements. The food produced by our nutrition powder machine is in line with the national food safety and health standards, everything is safe and healthy ,ready to be eaten.

14.How much Does Baby Food Production Line Cost

Due to the different specifications, parameters, performance and other components of the nutritional powder machine, the price of the nutritional powder machine equipment is also different. Usually the price ranges from tens of thousands to hundreds of thousands, you can contact loyal to get a quotation, we will provide you with the most reasonable price.

15.Future of Baby Food Production Line

The baby nutrition powder production industry is full of business opportunities, especially the baby food supplement market. Enterprises should make full use of the current market opportunities, choose the most potential nutritional powder machine, go deep into the market, and strive to quickly grow into a leading nutritional powder enterprise with unique characteristics.

The development of the infant nutrition powder production industry has also driven the development of other related industries. The demand for infant baby powder food production lines is also increasing. In this case, in the food industry, buying a baby nutrition powder machine is a very good choice, and the nutrition powder production line will bring you a lot of profits.

16. About Shandong Loyal Industrial Co.,Ltd.

Shandong Loyal Industrial Co.,Ltd. is a professional and experienced manufacturer of nutritional powder processing and manufacturing machines. loyal has various nutritional powder machines and nutritional powder production lines. We provide formula of baby food powder, technical support of nutritional powder machine, testing service of nutritional powder production line, etc. With rich experience in design and production of nutritional powder production line and advanced technology, our nutritional powder machine enjoys a large market share; we have won a high reputation among customers all over the world.

As a veteran in the nutritional powder production industry, loyal has achieved steady development in the nutritional powder production industry. Looking forward to the future, loyal has a foreign trade team with strong strength, strong ability and team spirit. We provide you with the highest quality nutritional powder production line. We have a group of skilled nutritional powder production line experts and excellent nutritional powder machine engineers, providing professional service, delivery and installation support. We also provide customers with design drawings of nutritional powder production lines according to their specific requirements. believe us! and choose us!

17. Our Advantages:

(1) Years of professional experience

Our baby powder food production line designers are experienced, and everyone has acquired excellent nutritional powder machine design technology

(2) High-quality machinery

We have a complete nutritional powder production line process and nutritional powder machine quality control system to provide customers with guaranteed high-quality products.

(3) Experienced team

We have many years of professional experience in nutritional powder manufacturing and market development and a highly educated professional team.

(4) Extensive customer base

Our baby powder food production lines are sold all over the world. We have won the trust of customers with our excellent nutritional powder machine quality, reasonable nutritional powder production line price, and high-quality baby powder food production line after-sales service.

18. Our Services:

(1). loyal provides you with professional advice on market conditions of nutritional powder production line, related equipment of nutritional powder machine, nutritional powder manufacturing process, nutritional powder manufacturing material formula, nutritional powder product packaging, etc.

(2). loyal assists you to choose the nutritional powder production line equipment, design the nutritional powder processing and manufacturing process, and optimize the nutritional powder production line workshop layout.

(3). If necessary, loyal will provide your nutritional powder production plant with related assistance with nutritional powder machines.

(4). loyal replaces the material according to your nutritional powder machine and produces it on site.

(5).loyal will help you professionally design and manufacture nutritional powder production lines, test nutritional powder equipment, and provide training on baby food powder and machine usage according to customer requirements.

(6) loyal provides you with reasonable nutritional powder packaging and transportation solutions, dispatching technicians to install and debug, and train workers.

(7) The nutritional powder production line is guaranteed for one year; priority is given to supplying spare parts for nutritional powder machines; design and processing of similar spare parts for imported equipment.

Our baby food production line machinery is developed by our company based on previous experience in the production of nutritional powder production lines after listening to customers' opinions and analyzing the market. The nutritional powder production line is fully automatic. After upgrading, it has stable performance, convenient operation, high output and short production time, and overcomes all defects. If you have any needs for nutritional powder production line, please feel free to contact us, we will provide you with perfect help and look forward to cooperating with you.