300-500Kg/h Nutritional Powder Baby Food Processing Line For Beans Milk Powder

As a professional baby powder food machine supplier, our nutritional powder machines/nutritional powder production line design good manufacturing process . Baby food powder machinery can take rice flour, soybean flour, starch and others as raw materials,to make the instant nutrition rice powder for sales. One button machine starts, making bottle milk in 8S. Water temperature could be adjusted from 40℃ to 70℃. Water could be adjusted from 30ml to 270ml,±1% water random error. One machine for multi-function, not only for baby milk powder also for other powder drinks. Precise water and milk powder mixed proportion, fast preparation for baby feeding. Bottle checking safety sensor design, in case wrong operation lead water delivery. Water shortage warning system in case no water heating.

300-500Kg/h Nutritional Powder Baby Food Processing Line For Beans Milk Powder Specifications :

| Price | Contact Us |

| Brand Name | Loyal |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 20days / Baby Food Production Line |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification: | CE, ISO9001, SGS, BV |

300-500Kg/h Nutritional Powder Baby Food Processing Line For Beans Milk Powder Detail Introduction :

300-500KG/H NUTRITIONAL POWDER BABY FOOD PROCESSING LINE FOR BEANS MILK POWDER

Nutritional powder processing line uses rice, corn, beans and all kinds of grains as raw material. Though extruding, inflating, drying, crushing and mixing. It could produce many kinds of nutrition powder, such as baby rice powder, beans powder and so on. This line could finish all the process automatically from the feeding to the end. It has features of easy operation, without leak of powder dust, sanitation, saving energy and easy to add all kinds of raw materials and nutriment. This line could finish all the process automatically from the feeding to the end. It has features of easy operation, no leak of powder dust, sanitation, energy-saving and adding all kinds of raw materials and nutriment easily.

Nutritional powder processing line expertise in baby food, nutrition powder, instant drink mixes, instant fruit dessert. Ability to handle a wide range of raw materials by simply varying the temperature, moisture and drying parameters.

The raw materials can be a wide range of flours and starches, pure or blended, such as rice, soy, corn, oat, millet, wheat, sorghum, banana, cassava and potato.Various recipes are supplied, which can add vitamin, mineral and other nutritional substances to meet different nutritional requirements.

HOW TO PRODUCE THE BABY NUTRITIONAL POWDER?

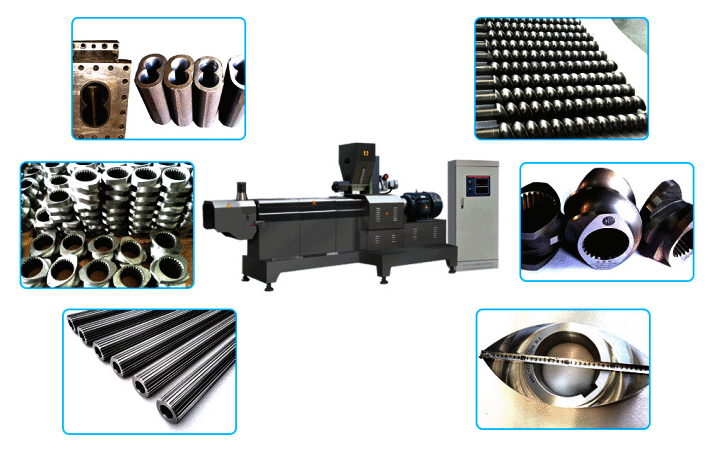

The machine is composed of feeding system, extrusion system, rotary cutting system, heating system, transmission system and control system. Adopt advanced screw extrusion technology, use high temperature and high pressure to mature and expand the material, complete at one time. The main engine adopts frequency conversion speed regulation to ensure the stability of the production process. The products are colorful, diverse in variety, beautiful in appearance, natural and lifelike, delicate in texture and widely used in raw materials.

FLOW CHART OF 300-500KG/H NUTRITIONAL POWDER BABY FOOD PROCESSING LINE FOR BEANS MILK POWDER

Mixer--Screw conveyor--Twin-screw extruder-- Air conveyor--Dryer--Air conveyor--Milling system

Capacity: 120-150 KG/H, 200-250 KG/H, 400-500 KG/H, 800-1000 KG/h

| FLOW CHART OF 300-500KG/H NUTRITIONAL POWDER BABY FOOD PROCESSING LINE FOR BEANS MILK POWDER | |

| Machine Name | Function |

| Mixer | Mix the material,make full mix |

| Screw conveyor | Conveying the material into the extruder |

| Twin-screw extruder | Extruded the material,make it become the puffing fish food. |

| Air Conveyor | Conveying the product |

| Dryer | Baked the product, removing the surface's water |

| Milling system | Ground into a powder |

WHAT CAN WE OFFER TO CUSTOMER?

PARAMETER OF BABY POWDER FOOD MACHINE

| PARAMETER OF BABY POWDER FOOD MACHINE | ||||

| Different Model Of Baby Powder Food Machine For Sale | ||||

| Model | NBP65 | NBP70 | NBP85 | NBP95 |

| Installed Power | 55 KW | 70 KW | 120 KW | 200 KW |

| Power Consumption | 40 KW | 50 KW | 95 KW | 180 KW |

| Output | 100-150 KG/H | 200-250 KG/H | 500-700 KG/H | 800-1000 KG/H |

| Size (L*W*H) | 19000*1300*2200mm | 21000*1300*2200mm | 28500*3500*4300mm | 30000*1500*2600mm |

ADVANTAGES FOR 300-500KG/H NUTRITIONAL POWDER BABY FOOD PROCESSING LINE FOR BEANS MILK POWDER

| ADVANTAGES FOR 300-500KG/H NUTRITIONAL POWDER BABY FOOD PROCESSING LINE FOR BEANS MILK POWDER | |

| 1 | Baby nutrition power processing line transforms the method from raw grain cooking into high-temperature and high -pressure method,and then is extruded fastly, It has characters of high automatic, easy operation. |

| 2 | Infant food machine making the rice powder food are used worldwide to nourish young children be in favor of the absorption. |

| 3 | Infant food machine enable precise cooking of raw materials allow manufacturers to process a wide range of recipes ensuring consistent quality and optimum food safety. |

| 4 | Precise control of all parameters to produce high quality products, Reduced production costs compared to traditional technologies (drum drying) |

| 5 | Compact design, reduced footprint |

| 6 | Food safety and traceability |

DETAILS ABOUT 300-500KG/H NUTRITIONAL POWDER BABY FOOD PROCESSING LINE FOR BEANS MILK POWDER

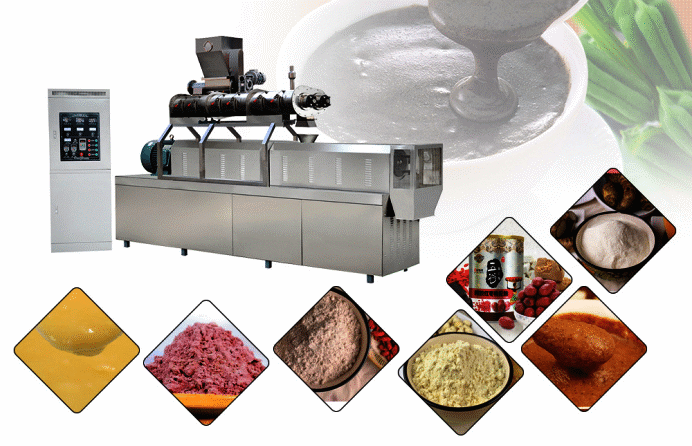

SAMPLES OF 300-500KG/H NUTRITIONAL POWDER BABY FOOD PROCESSING LINE FOR BEANS MILK POWDER

1.Raw Materials: Corn, Beans and All Kinds of Grains

2.The nutritious rice flour production line can make many different kinds of nutrition powder/nutrition porridge for old man, for baby food, baby rice powder, sesame paste, beans powder etc parts sample pictures like below:

LOYAL’S CUSTOMER AND FACTORY

Our company has already exported countries

Asia {Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan}

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine }

North & South America { Canada, Brazil, Bolivia }

Oceania { New Zealand }

LOYAL’S PACKING AND SHIPPING

Packed by standard Fumigation wooden case outside and wrapped by plastic film inside

then shipped by container,which is suitable for long time sea shipment.

20 ft container or 40ft container

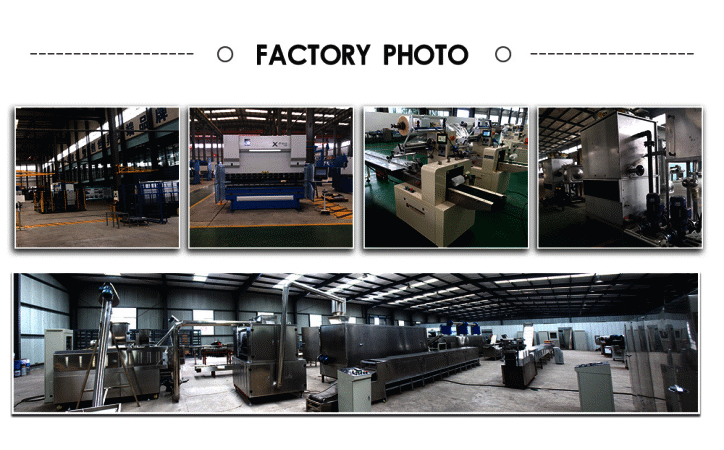

WHY CHOOSE US?

The customer can inform machine related problems to us via telephone, email or fax. All information will be recorded and will be reported to the After-sale Service team. Meanwhile, the sales person will be tracking the case until problem solved. We have a professional After-sale Service team including 10 professional engineers with at least 6 years working experience. They can handle technical consultation about manufacturing process, maintenance, fault diagnosis and troubleshooting, etc.

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001.

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, snack machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, instant noodle machinery, pasta machinery, etc. - food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions and better after-sales service.

LOYAL’S SERVICE

| LOYAL’S SERVICE | |

| Service for Pre-sale | Service for After-sale |

| 1.Provide technical parameter 2.Factory layout and size suggestion 3.Provide general formulation 4.Custom-Design service 5.Professional Advice about Market, machines, materials, packing 6. Suggesting professional ship agent or helping book ship as customer request. 7. 24 hours online service. | 1.Allocation chart as the buyer's request will be supplied. 2.Operation manual will be supplied after shipment. 3.One year warranty, life time maintenance with cost price. 4.Free easy broken spare parts will be sent with container . 5.First installation can be done by engineer. 6.Training workers in customer's factory. |

Engineers available to service machinary overseas.

1.Free consultation service before, during, and after sales;

2.Free project planning and design services;

3.Free debugging of equipment until everything is functional;

4.Free management of equipments' long distance shipping;

5.Free training of equipment maintenance and operating personally;

6.Free new production techniques and formulas;

7. Provide 1 year complete warrantee and lifetime maintenance service

What the Baby Food Powder Machinery Has Been Loyal Sold In 2021?

| Customer Case Of Stainless Steel Commercial Baby Food Powder Machinery At 2021 | |

| 1 | 600kg/h Baby Food Powder Machinery 100kg/h in Belarus manufacturer |

| 2 | 50kg/h Baby Food Powder Machinery for sale in Austria manufacturer |

| 3 | 100kg/h Baby Food Powder Machinery to Sri Lanka |

| 4 | 500-600kg/h Stainless Steel Commercial Baby Food Powder Machinery for customer‘s factory |

| 5 | 100kg/h Stainless Steel Commercial Baby Food Powder Machinery sold in Russia |

| Customer Have Factory Case Of Baby Food Powder Machinery At 2021 | |

| 1 | 200kg/h Stainless Steel Commercial Baby Food Powder Machinery for sale in bolivia for customer’s factory |

| 2 | Mozambique 150kg/h Stainless Steel Commercial Baby Food Powder Machinery to Lithuania |

| 3 | 300kg/h Stainless Steel Commercial Baby Food Powder Machinery for sale in Portugal manufacturer |

| 4 | Mozambique 250kg/h stainless Steel Commercial Baby Food Powder Machinery manufacturer |

| 5 | 600kg/h Stainless Steel Commercial Baby Food Powder Machinery for sale in North Korea for customer’s factory |

Baby Food Powder Machinery video