As a corn flake production line manufacturer, loyal's small corn flakes making machine design drawing is summed up by a number of flakes making machine technical engineers with more than ten years of experience. loyal has a number of project technology patents related to corn flake production, which can be used for you provide the most detailed corn flakes manufacturing recipes and corn flakes manufacturing process documents, saving the corn flakes making machine cost while better developing in the corn flakes manufacturing industry, making your corn flakes manufacturing project profitable of the corn flakes manufacturing industry.

Loyal's services range from the design of the maize flakes making machine to the after sales service of the corn flakes processing line. Loyal can help you make a corn flakes manufacturing business plan according to your actual needs, and provide you with technical training related to corn flakes manufacturing. Loyal helps you make your corn flakes manufacturing project bigger and stronger.

Corn Flakes Production Line Recommend Products

Corn Flakes Production Line Video

Corn Flakes Production Line Detail Introduction

Loyal corn flake production line is developed and manufactured based on the combination of previous experience, listening to customers’ opinions and analyzing the market, which is the result of Loyal careful design and joint efforts. As soon as the corn flakes production line was launched, it was well-received by our customers and was well supported and trusted by them.

At present, the corn flakes processing line sells well. Corn flakes production line not only has a broad market in China, but also popular in foreign countries. Corn flakes production line has been sold to Brazil, Britain, Myanmar, Australia, Pakistan and many other countries, where it gets a very good response.

As a common food in people's daily life, corn flakes are very popular, nutritious and delicious. Consumers also use corn flakes as regular food. Its development prospects are very broad. Therefore, the corn flake production line is a very good choice for investment.

The corn flake production machine is newly made by Shandong Loyal Industrial Co.,Ltd.. After abandoning the shortcomings of the previous equipment, there are many new superior performances. The corn flakes making machine has characteristics of high quality, high efficiency, cost savings and high economic benefits.

Corn Flakes Production Line refers to an industrial setup designed for the large-scale manufacturing of corn flakes, a popular breakfast cereal. This line consists of various specialized machines and equipment organized into several key stages, including raw material handling, mixing, extrusion shaping, baking, cooling, coating, and packaging. Modern corn flakes production lines incorporate advanced automation systems to maintain consistency in production efficiency and product quality.

Corn flakes manufacturing process Flow Chart

Raw materials → screening → wetting → peeling, degerming → crushing → extrusion ripening→ cooling → pressing → baking → spraying → micro-baking → cooling → packaging.

Brief Introductions of the Manufacturing Process

Shandong Loyal Industrial Co.,Ltd. must use the peeled and degermed corn as raw materials. To make bubbles even in the later stages, crush the corn into fine particles of about sixty mesh. Mix the corn flour with steam in the modulator, and then cook and granulate in a puffing machine.

After the particles are cooled, they enter a new type of tablet press, which adopts water-cooled constant temperature. Thus adhesion can be effectively avoided. The patented extruded snacks manufacturing process makes the tablets more uniform in shape and higher thickness uniformity.

After flaking, put them into the high-temperature airflow puffing furnace at 300℃-- 320℃. Within about 2 minutes, fully-puffed corn flakes with even bubbles will be made, whose color is attractive golden yellow.

To make various flavors of corn flakes, spray different flavors of materials evenly on the surface of the puffed corn flakes. Thus different flavors of corn flakes are made. Then put them into the microwave oven for sterilization and drying of the surface coating.

Finally, package the finished products. After the packaging is completed, it enters major supermarkets and is then purchased by consumers

Introduction of corn flakes production line | |

| Name | Brief introduction |

| Raw material | Corn, rice, wheat, oat, barley powder |

| Basic Recipe | Grist powder; sugar; coco; cheese; water |

| Processing flow | Mixing system; Extrusion system; Flaking system; Drying system; Flavoring system; Drying system; Packing system |

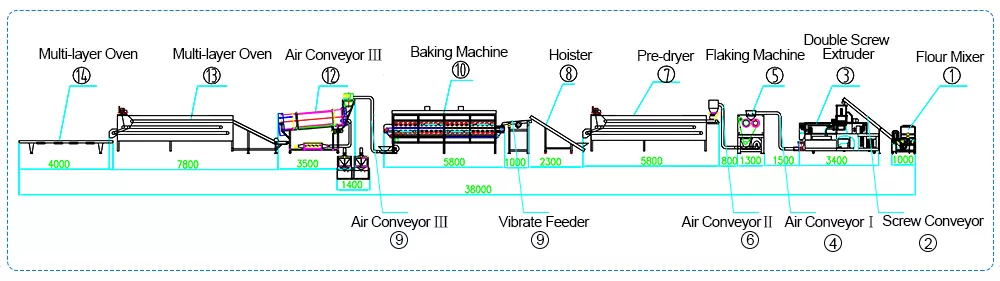

| Equipment involved | Mixer; Screw elevator; Double screw extruder; Air conveyor; Roller dryer; Tablet machine; Air conveyor; Dryer; Hoister; Vibrator; |

| Hot air dryer; Flavoring system; Dryer with cooler. | |

| Final products | Variety shapes are available for ball, tube, stick, ring, |

| fruit loop, star, wheel and flower and heart shape by | |

| adjusting the mould in the extruder ; corn flakes; cereal snacks | |

| Machine material | Stainless steel 304 or as customer’s request |

More Instructions

Our corn flake production line is developed and designed with the latest technology, which is more time-saving and space-saving for production than the previous method of steaming. Corn flakes making machine greatly reduces working time and improves work efficiency.

The products processed by the corn flakes production line are uniform in particle size. It’s very beautiful and highly consistent in maturation. The food produced is nutritionally balanced, healthy and safe, which can meet the needs of consumers. People can eat with great confidence. It is beneficial to health.

If you buy our corn flakes making machine, Loyal can also provide you with a full set of related equipment. Corn flakes making machine helps save you more costs and brings you the maximum economic benefits. Therefore, you can reap the best benefits and get better development.

Perhaps, you are keen to know the corn flakes making machine price. You can rest assured that the corn flakes making machine price we offer will definitely make you satisfied. Loyal offers lower price with the same quality while Loyal offers higher quality with the same price. Loyal will not only provide you with high-performance equipment, but also give you the most favorable price. Loyal assure you of our high cost performance.

Shandong Loyal Industrial Co.,Ltd. enjoys a high reputation both at home and abroad. Loyal is highly trusted and supported by our customers. You can certainly trust us unconditionally. Whether in terms of corn flakes making machine quality or service of corn flakes making machine or any other aspects, Loyal is guaranteed.

If you buy our corn flakes making machine , Loyal will provide the best quality service, including pre-sale, sale and after-sale. In addition, there are a series of technical services of snacks manufacturing process , commissioning services of corn flakes making machine, installation services of corn flakes making machine, etc.. Loyal takes customer’ satisfaction as our pursuit. All our work is committed to making you satisfied and ensuring you free from worries.

If you have a need in this area, do not hesitate to trust and choose us. You will be happy with the choice at this time. We are looking forward to working with you to achieve win-win cooperation.

A Corn flake Production Line: A Complete Buying Guide

I'm sure you've eaten cornflakes before. The market for cornflakes is growing rapidly. Do you want to engage in this industry and make profit from it? Or maybe you already have a corn flake processing plant and are in need of a corn flake production machine. If you are, take a look at the following. This guide will give you a detailed introduction to cornflakes and their production process.

1. Corn Flakes and its Development Prospect.

Corn deep processing equipment process requirements and the importance of the process, for the food processing industry is very important, the requirements of the process is related to the quality of the food added out. For corn deep processing equipment, in the face of different food, the processing process used is different, and the processor must ensure that the material balance, stable quality, easy to operate and improve the quality of food, so the process requirements for processing equipment is very high. Loyal's corn flakes manufacturing machine can meet the product requirements for processing technology.

2. Brief Introduction of Corn Flake Production Line.

Cornflakes, which is a nutritious and convenient food, is produced by the corn flake production line. A prominent feature of cornflakes is that they are rich in complex carbohydrates and dietary fiber, such as vitamins and minerals. And they can also add cocoa and sugar, such as honey and maltose. They can be directly consumed after mixing with functional drinks such as coffee, milk and yogurt. Or you can eat them as sweet and crunchy snacks.

The breakfast corn flake production line is a fully automatic production line developed and produced by combining advanced European technology. The corn flakes production line takes corn, wheat, oats and other kinds of cereals as raw materials. Corn flakes making machine realizes steaming and maturing, granulating by twin-screw extruder. Then through the process of pressing, baking and spraying, it can make crunchy ready-to-eat breakfast corn flakes with original, sweet and salty flavors. The corn flakes production line can also produce various shapes of breakfast cereals.

3. Benefits of Corn Flakes Production Line

(1) The roller gap of the corn flakes processing line is adjusted by turbine and worm gear, and the adjustment effect is accurate and balanced.

(2) The hardness of the alloy coating on the surface of the pressure roller of the corn flakes processing line is high, which greatly improves the service life.

(3) Corn flakes processing line is equipped with adjustable scraper and pressure roller oil injection system to prevent the product from sticking to the pressure roller.

(4) The tablet press of the corn flakes processing line can supply cold water, and is equipped with a water cooling pipe to prevent the overheating of the pressing roller from affecting the product characteristics.

(5) The inlet and outlet shields of the high-temperature oven (which can be called a pass-through oven) of the corn flakes processing line adopt an openable structure, which is convenient for maintenance and cleaning.

(6) The box body of the corn flakes processing line adopts a double-layer aluminosilicate insulation board, and the pipe material adopts an aluminosilicate insulation layer.

(7) The combined hot air blower of the corn flakes processing line blows the high temperature hot air to the material from top to bottom to bake evenly. Each group of hot air blowers has independent air outlet and return air duct, and the thermal efficiency is higher.

List Of Corn Flakes Production Plant | ||

| Mix Machine | Automatic Batching System Of Corn Flakes Production Line | |

| Capacity | 200kg/H-1500kg/H | |

| Usage | Mixing Various Kinds Of Raw Material | |

| Working Principle | Automatic Weighing, Automatic Proportioning, Automatic Mixing | |

The Machines Needed To Make Products Of Different Shapes | ||

| Name | Doule Screw Extruder Of Corn Flakes Production Line | |

| Capacity | 400kg/H-600kg/H | |

| Usage | Raw Material Is Curing And Puffed In Extruder, Becoming Different Shapes Of Products With Moulds Changing. | |

| Working Principle | The Motor Drives The Stirring Cage, Automatic Water Adding Device And Pneumatic Discharge Valve | |

Machines That Dehydrate And Dry Products | ||

| Name | Corn Flakes Manufacturing Machine Drying System | |

| Capacity | 200kg/H-800kg/H | |

| Usage | Drying Products After Extruding | |

| Working Principle | The Heating Source Can Be Electric, Gas, Steam And Fuel. The Material Is Stainless Steel 304. It Consists Of Rack System, | |

| Conmbustion System, Dehumidifier System, Sheet Metal Insulation System And Controlling System. | ||

Machines Needed To Make Corn Flakes | ||

| Name | Tablet Machine Of Corn Flakes Production Line | |

| Capacity | 200kg/H-600kg/H | |

| Usage | Make The Puffing Corn Granules To Corn Flakes | |

| Working Principle | The Motor Drives Two Pressing Rollers Rotating At Acontrary Direction Whose Speed Can Be Adjustable. | |

Machine For Crispy Cornflakes | ||

| Name | Gas Heating Hot Air Roaster Of Corn Flakes Production Line | |

| Capacity | 200kg/H-600kg/H | |

| Usage | Bubbles Will Appear On The Surface Of Corn Flakes , And After Hot Air Drying Corn Flakes Will Be Very Crispy . | |

| Working Principle | Heat Exchanger Is Burned By Gas Or Diesel Burner. Hot Air Is Sprayed By High Pressure Blower , Which Makes Corn Flakes Puffed And Bubbles Instantly. | |

Extruded Snacks Manufacturing Process Machine | ||

| Name | Sugar Coating Machine of Corn Flakes Manufacturing Line | |

| Capacity | 200kg/H-600kg/H | |

| Usage | This Device Is Applicable To A Wide Range Of Puffing Corn Snacks And Fried Snacks In Seasoning And Coating Oil Or Sugar | |

| Working Principle | Spraying Nozzle Can Adjust Oil Amount Equally. The Sugar Coating Is Built Up By Tumbler System. The Tumbler Is Derived By A Motor, Using For Mixing And Melting The Water, Sugar And Other Additives. | |

Machines That Dehydrate And Dry Products | ||

| Name | Drying System of Corn Flakes Manufacturing Machine | |

| Capacity | 200kg/H-600kg/H | |

| Usage | To Take Out The Extra Moisture From The Sugar Coated Corn Flakes | |

| Working Principle | The Heating Source Can Be Electric, Gas, Steam And Fuel. The Material Is Stainless Steel 304. It Consists Of Rack System, | |

| Combustion System, Dehumidifier System, Sheet Metal Insulation System And Controlling System. | ||

4. Limitation of Corn Flakes Production Line

No equipment is perfect. Since there are advantages, there will certainly be some shortcomings. Although the corn flake production line has been improved to a large extent, but it still needs to be improved in some aspects. For example, there are some energy waste or raw material waste in the production process, which will increase the cost.

In addition, with the improvement of people's consumption level, higher demands are also placed on the quality of corn flakes. The corn flake production line should also make improvements to ensure that the produced cornflakes meet the food hygiene and safety standards. Meanwhile, it should be more rationalized to make different kinds of food products so as to meet the different needs of consumers.

5. How Corn Flakes Production Line Works

After years of production and practice, the corn flakes manufacturing process has been greatly improved. The degree of automation is getting higher and higher. Advanced industrial corn flakes making machine and assembly corn flakes production lines have formed the following modern corn flake production process.

Mixing ingredients → twin-screw extrusion maturation → cutting and forming → pre-drying → pressing → high temperature baking → corn flakes

(1) Ingredients. The composition of the corn flakes made by the corn flakes making machine is very important. Make sure the seasoning tastes good. Pay attention to the ratio and content of various nutrients. After being prepared according to a certain proportion, it can be put into the corn flakes making machine for processing.

(2) Extrusion and curing. During the working process of the corn flakes making machine, the extrusion and ripening process of corn flakes is the key to producing high-quality corn flakes. During this process, the corn must be fully cooked without any puffing. Only in this way can you make dense, crisp, and flavorful tortilla chips.

(3) Cut. When the corn flakes production line is working, the material extruded by the twin-screw extruder and curing machine is cut into granular materials of uniform size, which are translucent.

(4) Pre-drying. The molding material is cut into the dryer for pre-drying. After the surface is dried, a certain tension is formed, and it is no longer sticking to each other, which is conducive to the smooth progress of pressing and the next work of the corn flakes making machine.

(5) Repression. The pressing process is also the key to the corn flakes production line. Tablet presses are very demanding. The surface of the roll must have a high smoothness and the roll must be constant temperature.

(6) High temperature baking. Whether the corn flakes product has a hard, brittle, dense structure and outstanding corn-specific flavor, the baking process is very important in the entire corn flakes production line.

(7) After the baked corn flakes are cooled, a corn flake product is prepared. There are some post-processed corn flakes, coated with sugar or chocolate, mainly based on market demand, and loyal's corn flakes production line can meet these requirements.

Corn Flakes Production Line Machine Composition | |||||

Corn Flakes Plant Equipment | Capacity | Voltage | Power | Weight | Dimension |

Corn Flakes Raw Material Mixing Machine | 600-800Kg/H | 220V-3 | 0.75Kw | 100Kg | 650*550*900mm |

Corn Flakes Extrusion Machine | 1000Kg/H | 220V-3/380V-3 | 0.75Kw | 400Kg | 2000*650*1300mm |

Corn Flakes Peeling Machine | 100-150kg/H | 380V/50Hz | 44.0Kw | 300Kg | 2000*2000*1700mm |

Corn Flakes Drying Machine | 300Kg/H | 380V/50Hz | 1.5Kw | 100Kg | 1200*1200*1400mm |

Corn Flakes Seasoning Machine | 1000Kg/H | 380V/50Hz | 0.75Kw | 400Kg | 1900x800x1000mm |

Corn Flakes Packaging Machine | 300Kg/H | 380V/50Hz | 1.5Kw | 200Kg | 1500*700*1600mm |

6. Parts of Corn Flakes Production Line

(1) Mixer. Mix corn meal or corn grits with nutritional additives and a proportion of water. This is the first step in the work of the corn flakes processing line.

(2) Feeder. Feed the mixed material into the hopper of the extruder. This is the second step in the work of the corn flakes processing line.

(3) Extruder. The raw material enters the hopper. In a pressurized system, small spherical particles are produced. This is the third step in the work of the corn flakes processing line.

(4) Vibrating screen. The granules are dispersed after entering the tablet machine, avoiding overlapping and pressing together. This is the fourth step in the work of the corn flakes processing line.

(5) Air conveyor. The granules are transported to the tablet press. This is the fifth step in the work of the corn flakes processing line.

(6) Tablet press. The pellets are pressed into flakes, known as corn flakes. This is the sixth step in the work of the corn flakes processing line.

(7) Blower. Send the cornflakes to the oven. This is the seventh step in the work of the corn flakes processing line.

(8) Multi-layer oven. Ovens are mostly electric ovens. The temperature is adjusted by the control cabinet between 0-200 degrees. The inner pocket is made of stainless steel double mesh. Baking time can be adjusted based on speed to remove moisture. This is the eighth step in the work of the corn flakes processing line.

(9) Seasoning thread. The seasoning line has octagonal cylinder, lifting cylinder, single cylinder and double cylinder. According to the output and product properties, there are oil spraying, sugar spraying and coating equipment. This is the ninth step in the work of the corn flakes processing line .

(10) Packaging machine. The finished pellets are conveyed to the crushing unit. This is the last step in the work of the corn flakes processing line .

7. Support Equipment to Buy with Corn Flakes Production Line

Basically, our corn flake production line can achieve the production of cornflakes. But you also need to buy some supporting equipment. We will provide related supporting equipment according to different needs of customers. Thus we can help you better complete the processing of products.

8. How to Verify Quality of Corn Flakes Production Line

The quality of your corn flakes making machine is a very important issue. You need to pay close attention to quality standards and check for ISO, CE, BV certification, which determines the quality of your corn flakes making machine, its length of service life and the health and safety of the food produced. The current Good Manufacturing Practices (cGMP) will ensure that your corn flakes making machine meets current production specifications.

9. Corn Flakes Production Line Validation Documents

After the verification of the corn flakes making machine, there will be some verification files of the corn flakes making machine, such as IQ authentication file, OQ verification file, FAT file, etc.. Each of these files has their own use. If these are available, it means that the corn flakes making machine is very secure and reliable, so you can buy it with confidence.

10. Industries using Corn Flakes Production Line

The corn flake production line is mainly used in food processing industry. Corn flakes making machine not only can make corn flakes, but also can make other cereals, breakfast cereals, etc.. By adjusting the molds in the filling, it can make various shapes of snacks, such as balls, tubes, sticks, rings, stars, wheels, flowers, hearts, etc.. There are many varieties, flexible configurations and a wide range of raw materials.

11. Types of Corn Flakes Production Line in the Market

Due to the different needs of customers, there are many kinds of corn flake processing equipment on the market. They are semi-automatic, fully automatic, small, medium, large, etc., . The corn flakes production line can also be customized according to the needs of customers, which will always meet the needs of customers.

12. How much Corn Flakes Production Line Cost

Many factors affect the corn flakes making machine price. As the type, performance and cost of the corn flake making machine are different, there is also a certain difference in price. Generally speaking, its price ranges from tens of thousands to hundreds of thousands. If you buy our corn flakes manufacturing machine, we will provide you with the most favorable and reasonable price. The more you buy, the higher the discount you have.

13. Corn Flakes Production Line Maintenance Process

Any equipment should pay attention to its daily care and maintenance. In the use of the corn flake making machine, the first thing you should pay attention to is its daily cleaning. Before using, check whether the corn flakes making machine parts are normal. Ensure that it will not appear damage, so that the work goes smoothly. While using, we should pay attention to observe the working condition of the various parts of the corn flakes making machine to avoid the emergency, such as damage to the corn flakes making machine, wear and tear of the parts, and poor product quality. After using, the corn flakes making machine should be timely added to the lubricant. Regular and proper maintenance can effectively reduce the cost of maintenance and extend the service life of the corn flakes making machine.

14. How to Troubleshoot Corn Flakes Production Line

Some faults may occur when the corn flake production line is in use. You can deal with the problems by following these steps.

(1) Formulate relevant corn flakes making machine management system according to specific corn flakes making machine performance. It is made by the equipment power department and issued to the workshop for implementation, so that the equipment management can be followed by rules.

(2) The corn flakes making machine documentation record forms are made by the equipment department. The operation is recorded by the workshop lead shift leader, including point inspection records, monthly inspection records, quarterly inspection records and other forms.

(3) Strengthen supervision. Set up an inspection team by the equipment department and production department to inspect the workshop from time to time every day.

(4) According to the detailed instructions of each corn flakes making machine, maintain and clean the equipment on time to ensure the maximum utilization of the equipment.

(5) The production department and the corn flakes making machine department will make the relevant corn flakes making machine inspection instructions and issue it to the workshop shift leader, who will be responsible for observing and implementing it to increase the staff’s awareness of equipment maintenance.

15. Future of the Corn Flakes Production Line

Corn flakes are long lasting, portable, and can be eaten directly or processed into other foods. It is very popular and has a broad development market. As the corn flakes making machine for making corn flakes, the corn flake production line also has a broad development prospect.

Under the impetus of science and technology, corn flake making machine has been greatly improved. Overcoming the drawbacks of previous processing methods, corn flakes making machine has more superior performance and can produce higher quality products. It is a very good choice to invest in this area. This is a new development opportunity. The future will have a broader market.

16. More information about Shandong Loyal Industrial Co.,Ltd.

Shandong Loyal Industrial Co.,Ltd. is a professional manufacturer of food machinery, with many years of manufacturing experience. The corn flakes making machines we produce have won the support and trust of our customers. The corn flakes making machines are all very reliable. With superior performance and a variety of types, corn flakes making machine can meet the different needs of our customers.

With the development of Loyal, our products have been exported to more than eighty countries such as the USA, Poland, Canada, Mexico and Brazil. We always try our best to meet the potential needs of our customers. The trend of economic globalization develops with irresistible force. Loyal is willing to cooperate sincerely with enterprises all over the world to achieve a win-win situation.

17. Quality Control of Equipment

(1) Pre-design control of corn flakes production line

On the basis of the test of the corn flakes making machine, the technicians of the corn flakes manufacturing machine will design a reasonable corn flake production line according to the actual situation and requirements of the customer's corn flake production plant, power, location, etc.

(2) Spare parts selection criteria for corn flakes making machine

After strict screening of suppliers' products, suppliers of corn flakes maker machine parts make purchases. On the premise of ensuring the quality of the corn flakes production line, we managed to reduce the cost of the corn flakes making machine. So customers can buy a cost-effective corn flake machine. For the same kind of external components, Loyal guarantees that there will always be 3 suppliers, which truly achieves the survival of the fittest.

(3) Production control of corn flakes production line

After the sales department receives the order, it will be submitted to the corn flake machine technology department, and the corn flakes maker machine technology department will issue the corresponding CAD drawings of the corn flake production line according to the order. According to the CAD drawings of the corn flake production line, the production department arranges relevant departments to purchase the raw materials of the corn flake machine, produce the corn flake making machine, and process the corn flakes manufacturing machine.

18. Our Services

(1) loyal will provide you with consultation on market conditions related to maize flakes making machines, equipment consultation for corn flakes processing lines, consultation on extruded snacks manufacturing process, consultation on raw and auxiliary materials required for corn flakes production lines, and packaging for corn flakes production lines Consultation, etc.

(2) Assist you in the selection of corn flakes making machines, the processing design of the corn flakes processing line, and the optimal layout of the corn flakes manufacturing production line. Helping you build a small scale corn flakes production plant. If you need, the loyal will come to you and help you make a corn flakes manufacturing business plan.

(3) loyal can design the compensation plan for the change of raw materials in the corn flake production line, conduct on-site demonstration, and provide the basic formula for the production of various corn flakes.

(4) loyal can carry out the design, manufacture and application test of a special corn flakes making machine according to your needs, and provide targeted training.

(6) loyal can design a reasonable packaging and transportation plan for you. Send technicians to your factory to install and debug the production line of corn flakes, and train the staff on how is corn flakes made in factories and the manufacturing technology of ready-to-eat cereals . Let you become a professional corn flakes manufacturer.

If you need to buy a corn flake making machine or have other needs, feel free to contact us! Loyal hope our corn flakes making machines and services can help you achieve your personal career goals. We would like to become your long-term partners and heartfelt friends with our sincerity and enthusiasm. Welcome to visit our factory!