Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake

Corn Flakes Making Machine is suitable for the production of various instant breakfast nutritious foods, which can retain the nutrient content of the product to a large extent and provide consumers with natural green food.Breakfast cereals corn flakes, as a convenient, fast, nutritious and relatively balanced food, quickly entered thousands of households. In modern processing, an extruder is usually used to complete the full kneading, steaming, cooking, and pelletizing of the corn flour mixture after adding water. Corn flakes are rich in nutrition and relatively balanced. They are rare cereal breakfast foods and are usually eaten with milk.

Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 3days--7days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Self Cleaning Automatic Corn Flakes Making Machine Twin-Screw Extrusion For Cereal Flake Detail Introduction :

Brief Introduction Of Self Cleaning Automatic Corn Flakes Making Machine

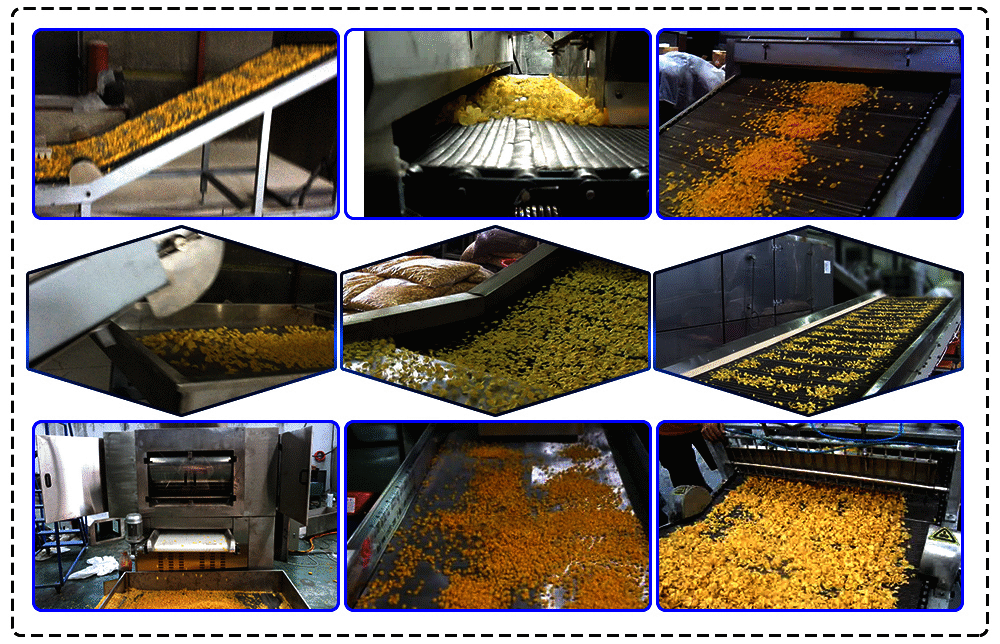

Breakfast cereal corn flakes are a kind of brittle food, with good rehydration, not rotten on the outside, smooth mouthfeel, and strong grain flavor. Corn flakes are mainly made of corn flour, mixed with sugar, various vitamins, and minerals. After adding a certain amount of water, they are fully kneaded, matured, formed, pressed, and baked and seasoned.

Breakfast cereals corn flakes, as a convenient, fast, nutritious and relatively balanced food, quickly entered thousands of households. In modern processing, an extruder is usually used to complete the full kneading, steaming, cooking, and pelletizing of the corn flour mixture after adding water. Corn flakes are rich in nutrition and relatively balanced. They are rare cereal breakfast foods and are usually eaten with milk.

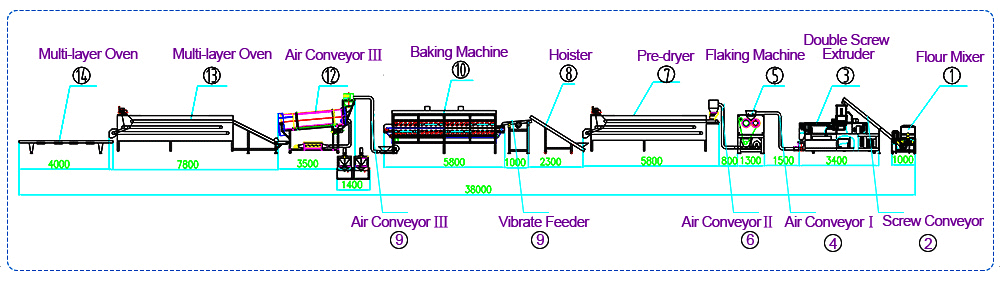

Process Flow Of Of Self Cleaning Automatic Corn Flakes Making Machine

Raw material preparation→powder mixing→conveying→extrusion→conveying→tabletting→conveying→drying→(packaging)

Device Configuration Of Self Cleaning Automatic Corn Flakes Making Machine

Powder mixer→feeding machine→puffing machine→air conveyor→tabletting machine→air conveyor→multi-layer oven→(packaging machine)

Technical Parameters Of Self Cleaning Automatic Corn Flakes Making Machine

| Technical Parameter of Commercial Corn Flakes Making Machine | ||

| Host model | LY70 | LY85 |

| voltage | 380V/50HZ | 380V/50HZ |

| Installed power | 186KW | 240KW |

| Actual power consumption | 116KW | 170KW |

| Production capacity | 180-220Kg/h | 300-500Kg/h |

| Production line length | 50m | 50m |

Process Composition Of Self Cleaning Automatic Corn Flakes Making Machine

| Equipment List of 100kg/h Corn Flakes Making Machine | |

| 1. Flour mixing machine | Add corn flour or corn dregs to nutrient additives and a certain proportion of water to mix evenly. |

| 2. Feeder | convey the mixed raw materials to the feeding hopper of the extruder. |

| 3. Extruder | The raw materials in the feeding hopper enter the extrusion system to produce small spherical particles. |

| 4. Vibrating screen | to disperse the particles and avoid overlapping and pressing together after entering the tablet press. |

| 5. Air conveyor | convey the particles to the tablet press. |

| 6. Tablet press | Press small spherical particles into flakes, namely corn flakes. |

| 7. Air conveyor | convey the corn flakes into the oven. |

| 8. Multi-layer oven | The oven is mostly electric oven. The temperature is adjusted between 0-200 degrees through the control cabinet. The inside is a stainless steel double-layer mesh bag. The baking time can be adjusted according to the speed to remove moisture. |

| 9. Packaging machine | there are vertical packaging machine and combined packaging machine |

Raw Material Of Self Cleaning Automatic Corn Flakes Making Machine

Corn flour, sugar, salt, other nutrients

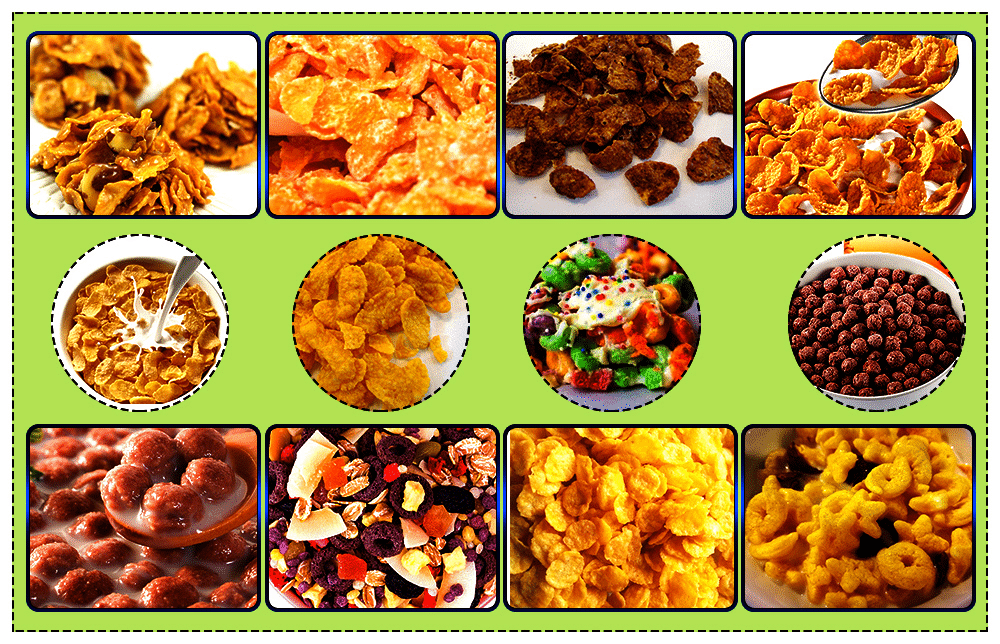

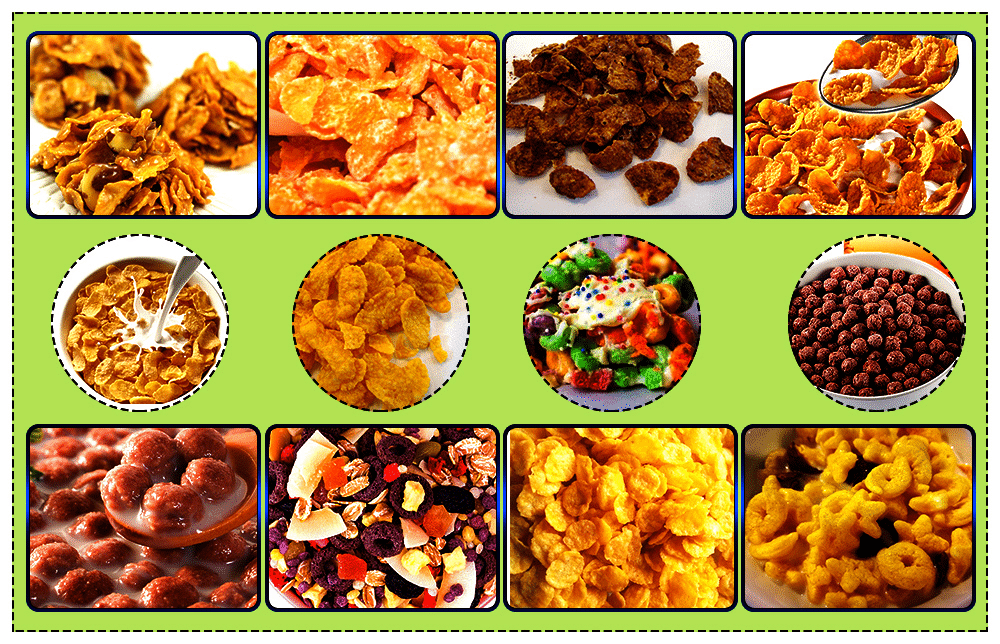

Output Of Self Cleaning Automatic Corn Flakes Making Machine

120-150kg/h, 200-250kg/h,400-500kg/h

Voltage Of Self Cleaning Automatic Corn Flakes Making Machine

Three-phase: 220V/H0HZ;380V/50H; 415V/50HZ can be customized.

Features Of Twin-Screw Extrusion For Cereal Flake

| Features of Corn Flakes Extruder Machinery | |

| 1 | The equipment is hygienic, safe and reliable. |

| 2 | No pollution, no pollution to the environment. |

| 3 | The equipment is integrated with the assembly line, and the appearance is beautiful and generous. |

| 4 | The equipment is easy to operate and has a high degree of automation, saving time and effort, and reducing labor consumption. |

| 5 | It is suitable for the production of various fast breakfast nutritious foods, which can retain the nutrient content of the product to a large extent, and provide consumers with natural green food. |

Technical Of Twin-Screw Extrusion For Cereal Flake

Skills: Material process moisture is relatively low. The energy consumption in the drying process of the oven is reduced, and the heat energy utilization rate is high, which is in line with the sustainable development strategy of mankind (similar baking equipment can reduce energy consumption by 25-40% compared with traditional baking equipment).

Environmental protection: When the materials are in the production state, there is no waste water, waste gas, or waste residue in the production process of equipment connection, and there is no loss of raw materials in the process.

Savings: less labor required per unit of product, small equipment space, large production capacity, large production capacity, stable and continuous production, and small fluctuations in product quality.

Flexible: Wide adaptability, can flexibly change products according to market demand.

Innovation: High-temperature puffing box furnace adopts high-temperature puffing, and the puffing has no paste phenomenon.

Tablet press: The press roller is processed with special materials, and the temperature in the press roller is cooled by water cooling cycle.

Traditional Corn Flakes Making Machine Vs New Corn Flakes Making Machine

| Traditional Corn Flakes Production Line VS New Corn Flakes Production Line | ||

| Features | Traditional Corn Flakes Production Line | New Corn Flakes Production Line |

| Use factory area | Big | Save factory area |

| Save energy | High energy consumption | Low energy consumption |

| safety | Low | High |

| Manual operation | 10 workers | 3-5 workers |

2021 Customer Order of Corn Flakes Making Machine Form:

| Customers Who Understand Corn Flakes Production Line Processing Technology | |

| 1 | Corn Flakes Production Line For Sale In Afghanistan |

| 2 | China Fully Automatic Corn Flakes Production Line For Sale In Argentina |

| 3 | High Quality Most Popular Industrial Corn Flakes Production Line For Sale In Comoros |

| 4 | Corn Flakes Production Line For Sale In Afghanistan |

| 5 | Corn Flakes Production Line For Sale In Argentina |

| Dealed Customers Who Purchase Big Output Corn Flakes Making Machine In 2021 | |

| 1 | Customized Corn Flakes Making Machine For Sale In Congo |

| 2 | 800kg/h Corn Flakes Making Machine For Sale In Denmark |

| 3 | 1000kg/h Corn Flakes Making Machine For Sale In Congo |

| 4 | Customized High Efficiency Corn Flakes Making Machine For Sale In India |

| 5 | 1000kg/h Corn Flakes Making Machine For Sale In Denmark |

| Dealed Customer Have Plant Of Corn Flakes Making Machine In 2021 | |

| 1 | Corn Flakes Making Machine For Sale In Fiji |

| 2 | High Efficiency Corn Flakes Making Machine For Sale In Fiji |

| 3 | High Efficient Industrial Corn Flakes Production Line For Sale In Germany |

| 4 | Corn Flakes Production Line For Sale In Germany |

| 5 | Industrial Corn Flakes Production Line For Sale In Fiji |

| Dealed Customer Whose Intruduction Of Old Customer Of Corn Flakes Production Line In 2021 | |

| 1 | Stainless Steel Corn Flakes Production Line For Sale In Laos |

| 2 | Stainless Steel Corn Flakes Production Line For Sale In Lebanon |

| 3 | Corn Flakes Production Line For Sale In Lesotho |

| 4 | Automatic Stainless Steel Corn Flakes Production Line For Sale In Mali |

| 5 | Fully Automatic Stainless Steel Corn Flakes Production Line For Sale In Nauru |