40-1000 KG/H Bread Crumbs Making Machine Continuous Production Line

Bread crumbs making machine is specially designed and developed according to market demand. Bread crumbs making machine is automatically completed from raw materials, extrusion, drying to finished products.40-1000 KG/H bread crumbs making machine continuous production line can produce widely used auxiliary materials. Mainly used in western foods, such as fried steak, frying, chicken legs, etc. It can increase the crispy taste. The working principle of bread crumb extruder machine is different from the traditional bread crumb process. Automatic bread crumbs production factory does not produce waste during the production, so the production cost is reduced.

40-1000 KG/H Bread Crumbs Making Machine Continuous Production Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 10-25 working days. |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

40-1000 KG/H Bread Crumbs Making Machine Continuous Production Line Detail Introduction :

Product Description of Bread Crumbs Panko Making Equipment:

40-1000 KG/H bread crumbs making machine continuous production line is specially designed and developed according to market demand. Bread crumbs making machine is automatically completed from raw materials, extrusion, drying to finished products. They are not only puffed and nice in appearance but also crisp and delicate in taste.

40-1000 KG/H bread crumbs making machine continuous production line can produce widely used auxiliary materials. Mainly used in western foods, such as fried steak, frying, chicken legs, etc. It can increase the crispy taste. The working principle of bread crumb extruder machine is different from the traditional bread crumb process. Automatic bread crumbs production factory does not produce waste during the production, so the production cost is reduced.

Details of Bread Crumbs Production Line

| Details Of Bread Crumbs Making Machine | |

| Bread Crumbs Raw Materials | This 40-1000 KG/H bread crumbs making machine continuous production line adopts cereals flour, corn, wheat, rice, oat, soy, sesame, walnut, black rice etc. |

| Bread Crumbs Machine Voltage | In China: Three phases: 380V/50Hz, Single phase: 220V/50Hz. We can design according to customers' local voltage from different countries. |

| Bread Crumbs Machines Materials: | All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function. |

| Bread Crumbs Machines Application | Food additive for deep fried food, and mainly for frying food surface, such as: fried chicken, fish, seafood (shrimp), chicken, chicken wings, onion rings, etc. Its feature is crispy soft, tasty, delicious and nutritious. |

Equipment List Of Automatic Bread Crumbs Production Factory:

Mixer→Screw conveyor→Twin Screw Extruder→ Multifunctional Shaper→Hoister→Crusher→Air conveyor→Drying Oven→Air conveyor→Sifter

Technical Parameters of Bread Crumbs Making Machine

| Technical Parameters of 40-1000 KG/H Bread Crumbs Making Machine Continuous Production Line | |||||

| Model | Installed Power | Actual Consumption | Main Power | Output | Dimension |

| LY65 | 34kw | 28kw | 22kw | 120-150kg/h | 2400*1200*1800 |

| LY70 | 42kw | 30kw | 30kw | 160-200kg/h | 2600*1200*1800 |

| LY85 | 92kw | 75kw | 75kw | 400-500kg/h | 4500*1600*2000 |

| LY90 | 135kw | 91kw | 75kw | 600-900kg/h | 4500*2000*2000 |

Features of Bread Crumb Extruder Machine:

| Features of 40-1000 KG/H Bread Crumbs Making Machine Continuous Production Line | |

| No. | Features |

| 1 | Different sizes of breadcrumbs use interchangeable screens of different sizes. |

| 2 | Easy to operate, adjustable and reliable. |

| 3 | The bearings and blades are easy to replace and maintain. |

| 4 | Easy to clean, in line with HACCP standards. |

| 5 | Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly. |

| 6 | Double screws feed equal materials forcibly. |

| 7 | Automatic lubrication system can lower down power consumption and prolong the life. |

| 8 | Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption. |

Extrusion Technology Of 40-1000 KG/H Bread Crumbs Making Machine Continuous Production Line

Compared with the traditional fermented bread crumb production line, the extrusion type bread crumb production line has the following advantages.

| Extrusion type bread crumbs production line VS Traditional fermented type bread crumbs production line | ||

| Aspect | Extrusion type bread crumbs production line | Traditional fermented type bread crumbs production line |

| Operation | Easy operation, simple | Have highly request for the teme |

| Finished products | Different shapes, taste more crispy and easy absorption | One shape, easy to be soft |

| Workshop | Small footprint, not too much request for the workshop | Required strictly for the work environment |

| Widely usage | Bread crumbs production line can produce the puffing snacks, bar snacks, pet food by changing the processing and formula | Only can make bread crumb |

Specifications Of Bread Crumbs Making Machine Motor:

| Specifications Of 40-1000 KG/H Bread Crumbs Making Machine Continuous Production Line Motor | |

| Attribute | Value |

| Power Rating | 5.5 kW |

| Frequency Rating | 50Hz |

| Efficiency Class | IE3 |

| AC Motor Type | Squirrel Cage Motor |

| Phase | 3 |

| Output Speed | 2914 rpm, 2920 rpm |

| Number of Poles | 2 |

| Mounting Type | Flange Mount |

| Current Rating | 5.72 A, 9.58 A, 9.84 A |

| Maximum Output Torque | 18Nm |

| Bearing Type | Deep Groove |

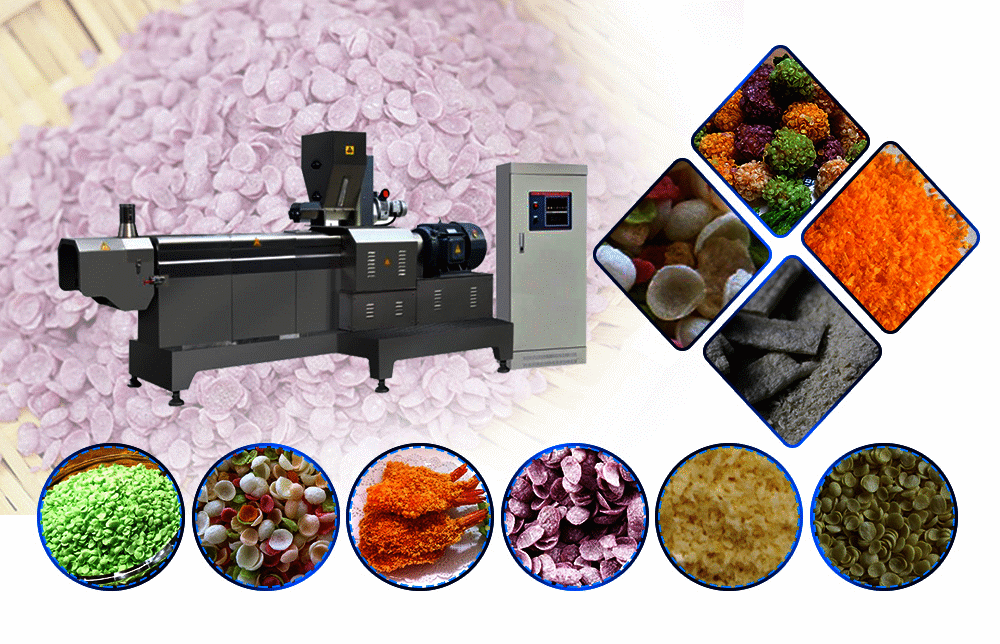

Pictures of Bread Crumbs Samples:

The 40-1000 KG/H bread crumbs making machine continuous production line can produce different shape and size bread crumbs by changing the crusher sieve. The Extruded Bread Crumbs are light and crispy with innovative shapes (small rings, crescent, small stars, balls, granule etc). They are widely used as food coating additives on the surface of frying food like: fried chicken, burger patty, sea foods (shrimp, fish), onion ring etc to obtain a very crispy and savory texture as well as unique and attractive fried foods’ golden color presentation.

Panko is a variety of flaky bread crumb used in many cuisines as a crunchy coating for fried foods, such as onion rings. It is made from bread baked by passing the electric current through the dough placed in the plastic box of Baking Machine's Trolley, yielding bread without crusts, then crushing the bread into bigger sizes bread crumbs. It has a crisper, airier texture than most types of breading made by Extruder and resists absorbing oil or grease when fried, resulting in a lighter coating. Outside Japan, its use is becoming more popular in both Asian and non-Asian dishes: Japanese style Panko breadcrumbs are also unseasoned and they taste great as a lightweight, crispy topping on French toast.

So they are widely used in many cuisines and industrial seafood and meat food process as topping, breading or crumbing. We would like to recommend you our 40-1000 KG/H bread crumbs making machine continuous production line to produce Panko bread crumbs.

2021 Customer Order of Bread Crumbs Processing Line Form

| Customers Who Understand Bread Crumbs Production Line Processing Technology | |

| 1 | Bread Crumbs Production Line For Sale In Afghanistan |

| 2 | China Fully Automatic Bread Crumbs Production Line For Sale In Argentina |

| 3 | High Quality Most Popular Industrial Bread Crumbs Production Line For Sale In Comoros |

| 4 | Bread Crumbs Production Line For Sale In Afghanistan |

| 5 | Bread Crumbs Production Line For Sale In Argentina |

| Dealed Customers Who Purchase Big Output Bread Crumbs Making Machine In 2021 | |

| 1 | Customized Bread Crumbs Making Machine For Sale In Congo |

| 2 | 800kg/h Bread Crumbs Making Machine For Sale In Denmark |

| 3 | 1000kg/h Bread Crumbs Making Machine For Sale In Congo |

| 4 | Customized High Efficiency Bread Crumbs Making Machine For Sale In India |

| 5 | 1000kg/h Bread Crumbs Making Machine For Sale In Denmark |

| Dealed Customer Have Plant Of Bread Crumbs Making Machine In 2021 | |

| 1 | Bread Crumbs Making Machine For Sale In Fiji |

| 2 | High Efficiency Bread Crumbs Making Machine For Sale In Fiji |

| 3 | High Efficient Industrial Bread Crumbs Production Line For Sale In Germany |

| 4 | Bread Crumbs Production Line For Sale In Germany |

| 5 | Industrial Bread Crumbs Production Line For Sale In Fiji |

| Dealed Customer Whose Intruduction Of Old Customer Of Bread Crumbs Production Line In 2021 | |

| 1 | Stainless Steel Bread Crumbs Production Line For Sale In Laos |

| 2 | Stainless Steel Bread Crumbs Production Line For Sale In Lebanon |

| 3 | Bread Crumbs Production Line For Sale In Lesotho |

| 4 | Automatic Stainless Steel Bread Crumbs Production Line For Sale In Mali |

| 5 | Fully Automatic Stainless Steel Bread Crumbs Production Line For Sale In Nauru |