Stainless Steel 3D Cereal Pellets Snack Production Line

Our 3D Cereal Pellets Snack Production Line is summed up by a number of 25 technical engineers who have more than ten years of experience. Loyal Snack Pellet Production Line has a number of 3D snack pellets project technology patents, which can provide you with the most detailed formula and process documents, which can save Snack Pellet Production Line costs while improving good development in the extruded snack pellets manufacturing industry. As one professional 3D Cereal Pellets Snack Machine manufacturer,we can offer small, medium and large equipment for sale. The multifunctional 3D Cereal Pellets Snack Machine has reasonable price, reliable quality and professional service!Our company provides customers full set service. Cost accounting,3D Cereal Pellets Snack Machine design, 3D Cereal Pellets Snack Machine recipes, machine installation and debugging, design 3D Cereal Pellets Snack Machine request according to customer requirements.

Stainless Steel 3D Cereal Pellets Snack Production Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 3days--7days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Capacity: | 80-500kg/h |

| Equipment Material: | Stainless Steel/Carbon Steel |

| HS Code: | 84388000 |

| Applicable Industries: | snack pellet Manufacturing Plant, snack pellet Beverage Factory, 3d snacks pellets |

| Condition: | New |

| Extruder machine suppliers: | Loyal Factory |

| Installation: | Engineer Guide |

| Function: | Multifunction |

| Place of Origin: | Shandong, China |

| Voltage: | customizable |

| Key Selling Points: | Competitive Price |

Stainless Steel 3D Cereal Pellets Snack Production Line Detail Introduction :

What’s The 3D Cereal Pellets Snack Production Line?

Product Application Of The 3D Cereal Pellets Snack Production Line:

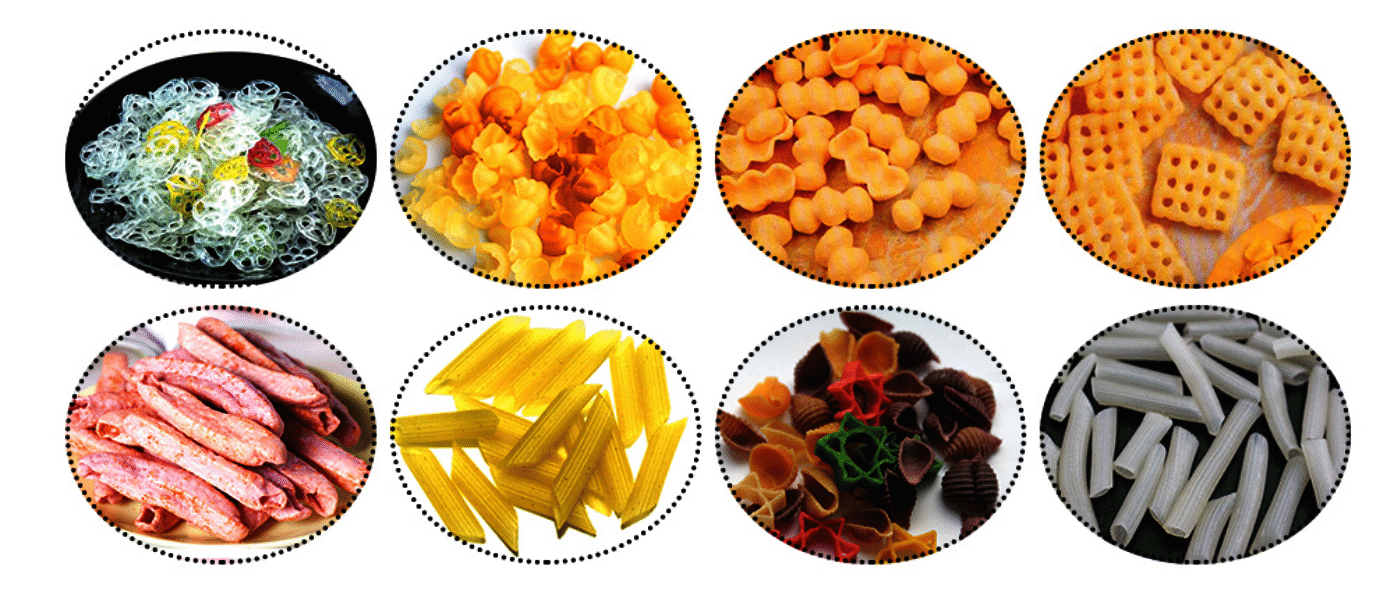

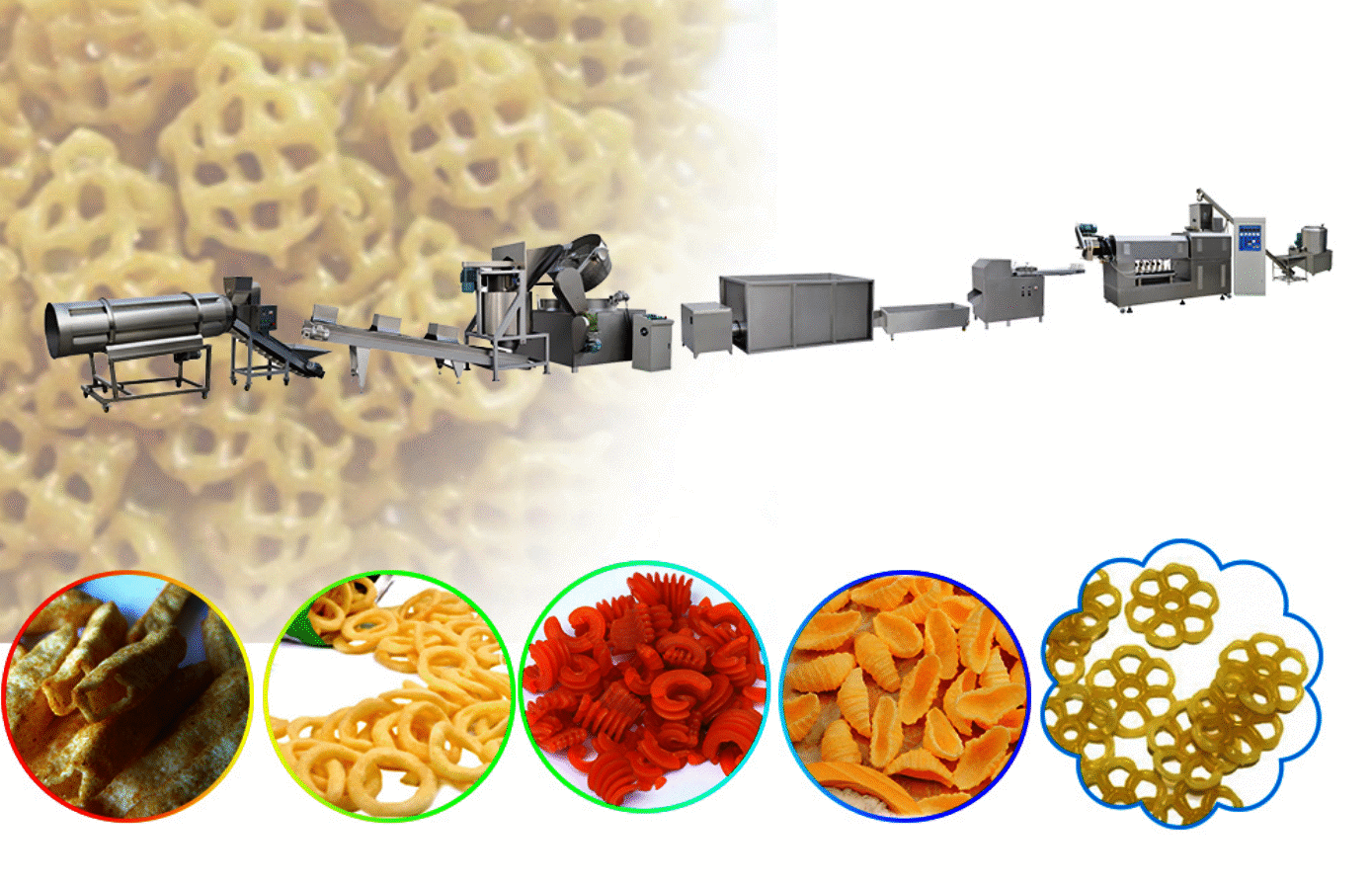

Today, there is a broad range of snack pellet in the market, thanks to the innovation technology with 2D & 3D pellet snacks machines, which processes a wide range of products in numerous styles, textures, shapes, and tastes. The 2D & 3D pellet snacks machines can produce products like: Punched pellets, Laminated pellets, Die distant cut pellets, Die face cut pellets, Wheat Pellets, Multi-cereal pellets, Potato pellets. In this article, we give the overview of 3D pellets machine, highlighting how they work, their features, benefits, productivity. Read on to make out whether this device is worth investing in or not.

How Are 3D Snack Pellets Made?

This snack pellet production line is the newly designed for pellet food products both 2D and 3D snack pellets. The raw materials are wheat flour, potato starch, potato flour, corn satrch, cassava starch, etc. This snack pellet extruder in big capacity is combined together two processes, one is pre-cooking the materials, and the other is extruding. With platform on the middle and safety guard on the top, it is easy to operate and observe during working. Such snack pellet extruder structure can make bigger capacity than the usual extruder, and also can deal with all kinds of raw materials for pellet food. 3D Cereal Pellets Snack Production Line’s multi-functional feature makes it more and more popular to those customers who want bigger capacity.

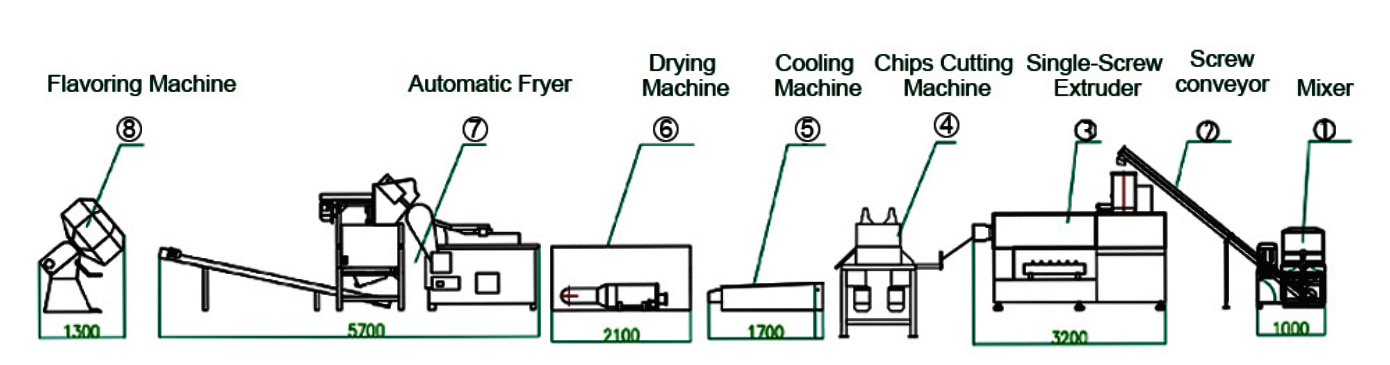

Flow Chart Of 3d Snacks Pellets Machine:

Flour Mixer - Screw Conveyor - Extrusion Machine - Shaping And Cutting Machine- Drying Machine - Frying Machine - Seasoning Machine - Cooling Machine - Packing Machine.

What Is The Recipe Of The Extruded Snack Pellets?

| Below Is The Ratio Of Raw Materials Required In 3D Cereal Pellets Snack Production Line: | |

| Potato Starch: | 45% |

| Whole Potato Flour: | 15% |

| Cornstarch: | 25% |

| Tapioca Starch: | 10% |

| Flour: | 5% |

| White Sugar: | 35% |

| Msg: | 3.5% |

| Salt: | 3.5% |

| Baking Soda: | 2% |

Depending on user’s recipe, ingredients such as flour, fibers, starches, and liquids are added to the batch mixer in their correct order then they are cooked, formed, cut and processed to produce an even mixture. This snack pellets manufacturing process takes place under regulated temperature and pressure. The biggest advantage of this extruder pellet machine is that it combines all the processes like mixing, baking, forming, cutting and drying are into one incorporated entity, reducing the hassle of moving products from one container to another, for further processing, like in traditional snack pellet extruder. Several shapes of the end product can be attained using the 2D & 3D variations of the snack pellet production line, depending on their die inserts. For instance, shapes like cones, wheels, animals and stars can be formed.

Parameters And Price List Of Snack Pellet Production Line:

What’s The Cost Of The Different Capacity Extruder Pellet Machine? | |||||

Model Of 3D Cereal Pellets Snack Production Line | Installed Power Of 3D Cereal Pellets Snack Production Line | Power Consumption Of 3D Cereal Pellets Snack Production Line | Capacity Of 3D Cereal Pellets Snack Production Line | Dimension Of 3D Cereal Pellets Snack Production Line | Price (USD) Of 3D Cereal Pellets Snack Production Line |

LY-65 | 60kw | 45kw | 100kg/h | 22000x2280x4550mm | 21,000-26,000 |

LY-70 | 70kw | 55kw | 200kg/h | 37000x3280x4550mm | 26,000-34,000 |

LY-75 | 90kw | 75kw | 300-400kg/h | 48000x4280x4550mm | 38,000-47,000 |

LY-80 | 110kw | 85kw | 500-800kg/h | 52000x8280x4550mm | 48,000-51,000 |

What’s The Main Machine In The food pellet making machine?

| Detailed Information Of The Main Machine In The 3D Cereal Pellets Snack Production Line: | |

Flour Mixer | Mixer Makes The Raw Material Adding To Water And Other Chemical Additive Fully Mixed |

Screw Conveyor | Screw Conveyor Can Not Only Convey On The Level But Also By Any Angel These Materials Can Be Conveyed In The Stainless Steel Roller Without Leaking, Dust Pollution |

| Snack Pellet Extruder | The Machine Is Composed Of Feeding System, Extrusion System, Heating System, Transmission System And Control System. It Adopts Advanced Screw Extrusion Technology And Uses High Temperature And High Pressure To Mature And Expand The Material Into One-Time Completion. |

| Pulling And Cutting Machine | 1. The Cutter Is Used To Cut Rectangular Tubes And Round Tubes. 2. The Pulling And Cutting Machine Consists Of Two Parts: The Cutting System And The Conveying System. 3. The Machine Is Easy To Operate, And The Length Of The Frequency Control Is Adjustable. |

| Hot Air Circulation Oven | To Dry Out The Extra Moisture Inside Of Snack Pellet. |

Continuous Fryer |

4. Belt Easy Lift Out Of The Fryer To Be Convenience Washing |

| Rolling Flavoring Machine | Spray Seasoning Oil And Powder Onto The Snacks So As To Make The Snacks Tasteful. |

2021 Customer Order Food Pellet Machine Form:

Our 3D Cereal Pellets Snack Production Line is summed up by a number of 25 technical engineers who have more than ten years of experience. Loyal Snack Pellet Production Line has a number of 3D snack pellets project technology patents, which can provide you with the most detailed formula and process documents, which can save Snack Pellet Production Line costs while improving good development in the extruded snack pellets manufacturing industry.

Which Market Did The Loyal 3D Snack Pellets Making Machine Sold To?

| Customers Have 3D Snack Pellets Formula Request Of 3D Pellet Snack Machine | |

| 1 | Spain 300T/Year Industrial 3D Cereal Pellets Snack Production Line Customer's Factory |

| 2 | 1T/H 3D Snacks Pellets Making Machine For Sale In Puerto Rico Pellet Machinery Agent |

| 3 | 1T/H 3D Pellet Snack Production Line For Sale In Bolivia |

| 4 | Senegal 1T/H Industrial 3D Pellet Snack Manufacturing Equipment |

| 5 | India 1T/H 3D Cereal Pellets Snack Production Line |

| 6 | 1T/H Industrial 3D Snack Pellets Production Line Fryums Making Machine Sold In Russia |

| Cooperated Customer Request Engineer Installation 3D Extruded Snack Pellets Machine At 2021 | |

| 7 | 100kg/H Industrial 3D Snacks Pellet Making Machine For Sale In Uzbekistan Customer's Factory |

| 8 | 100kg/h Industrial 2D And 3D Pellet Making Machine For Sale In Senegal Pellet Machinery Agent |

| 9 | Mozambique 1T/H Automatic 3D Pellet Making Machine Pellet |

| 10 | Bangladesh 2t/h Industrial Automatic 3D Snack Pellet Machine |

| 11 | 1T/H 3D Pellet Snack Production Line |

| 12 | Uzbekistan 1T/H 3D Snack Pellet Machine Manufacturing Equipment |

| 13 | USA 1T/H 3D pellet Snack Production Line |

| 14 | 50kg/h 3d Snack Pellets/Indian Pani Puri/Gollapa Pellets/Fried Snacks Production Line Making Machine For India |

| Second- Cooperation Customers Of 3d Pellet Snack Machine At 2021 | |

| 15 | Algerian 3D Snack Pellet Extruder Machine 300kg/h Production Line |

| 16 | Sudan 200kg/h 3D Snacks Pellet Making Machine |

| 17 | Moldova Small 200kg/h Automatic 2D And 3D Snacks Fryums Pellet Making Machine |

| 18 | 200kg/h 3D pellet Snack Machine Sold In Ukraine |

| 19 | Nigeria 150Kg/H 3D Snack Pellet Extruder Machine Customer's Factory |

| 20 | Austria Sells Industrial 3D Pellet Snack Machine 100kg/h |

| Cooperated Agent Of 2d 3d Snack Pellet Machine At 2021 | |

| 21 | Nigeria 150Kg/H 3D pellet Snack Making Machinery |

| 22 | Vegetable 2d 3d Snack Pellet Machine For Sale In Pakistan 100kg/h |

| 23 | Austria Sells Industrial 3D pellet Snack Machine 100kg/h |

| 24 | 500Kg/H 3d Snack Pellets/Indian Pani Puri/Gollapa Pellets/Fried Snacks Production Line Making Machine For Sale |

| 25 | Sudan 250kg/h Small 3D Pellet Production Line Agent |

| 26 | Algerian 3D Pellet Snack 300kg/h Production Line |