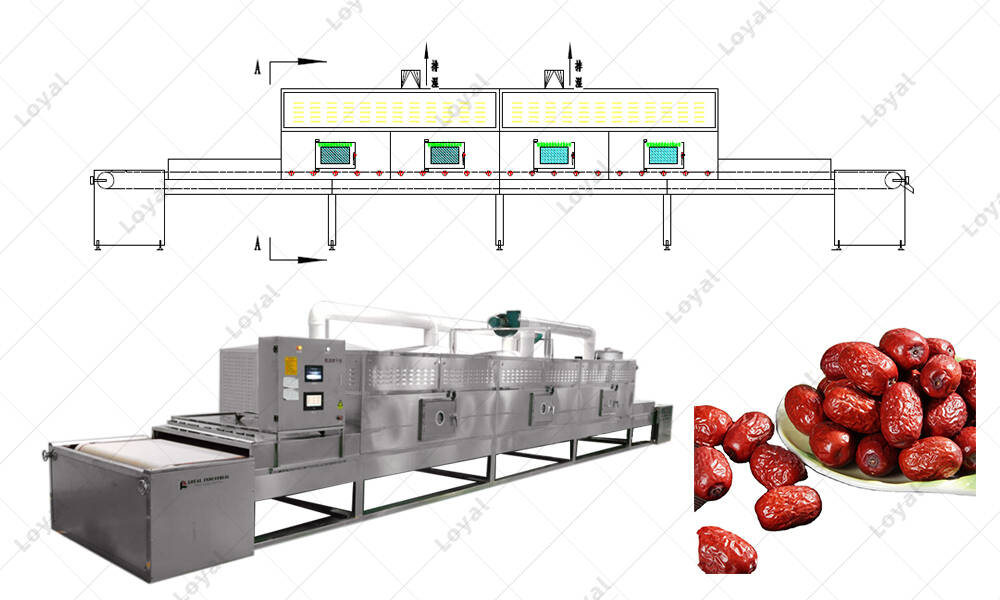

PLC Industrial Microwave Date Drying Sterilizing Machine

As a high-tech-oriented modern technology-based PLC Industrial Microwave Date Drying Sterilizing Machine enterprise integrating R&D and manufacturing, we produce industrial microwave dryer, microwave heating equipment, and microwave sterilization equipment. We have a strong technical development team of industrial microwave dryer, and have more than ten years of technical reserves for industrial microwave oven production technology research. We are a leading microwave equipment manufacturer in the domestic industry. The principle of Loyal continuous microwave oven equipment is to gradually increase the center temperature of the object. , called external heating. And the drying characteristics of industrial microwave dryer for dates, microwave energy can penetrate the inside and outside of the object to heat at the same time, the frequency is 2450MHZ, with 2.45 billion oscillations per second, the molecules rub against each other to generate heat, and self-heating, so as to achieve harmless for the purpose of sterilization and drying.

PLC Industrial Microwave Date Drying Sterilizing Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Industrial Microwave Date Drying Sterilizing Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Team | Industrial Microwave Date Drying Sterilizing Machine Team |

| Sales Team | Microwave Drying Sterilizing Machine Process Technology Engineer |

PLC Industrial Microwave Date Drying Sterilizing Machine Detail Introduction :

As a high-tech-oriented modern technology-based PLC Industrial Microwave Date Drying Sterilizing Machine enterprise integrating R&D and manufacturing, we produce industrial microwave dryer, microwave heating equipment, and microwave sterilization equipment. We have a strong technical development team of industrial microwave dryer, and have more than ten years of technical reserves for industrial microwave oven production technology research. We are a leading microwave equipment manufacturer in the domestic industry.

How Do You Dry Fresh Red Dates?

For the Sanitation and disinsectisation of dates, Conventional heating and sterilization methods such as flame, hot air, electric heating, steam drying, etc. all use the principle of heat conduction to transfer heat from the outside of the heated object to the inside. It takes a certain amount of time for conventional drying and sterilization to bring the central part to the required temperature, and it takes longer for objects with poor thermal conductivity.

The principle of Loyal continuous microwave oven equipment is to gradually increase the center temperature of the object. , called external heating. And the drying characteristics of industrial microwave dryer for dates, microwave energy can penetrate the inside and outside of the object to heat at the same time, the frequency is 2450MHZ, with 2.45 billion oscillations per second, the molecules rub against each other to generate heat, and self-heating, so as to achieve harmless for the purpose of sterilization and drying.

What’s The Parameters And Price Of The Industrial Microwave Dryer For Dates?

Industrial Microwave Oven Price And Equipment Parameters

NO. Model Of Industrial Microwave Drying Machine Power(kw) Of Industrial Microwave Drying Machine Dryer Capacity(kg/h) Of Industrial Microwave Drying Machine Price Of the Industrial Microwave Drying Machine Size(mm) Of Industrial Microwave Drying Machine

1 LY-12KWSP 12 12 11,000-13,000 7010*840*1750

2 LY-22KWSP 22 22 14,000-17,000 9350*840*1750

3 LY-40KWSP 40 40 18,000-21,000 10520*1060*1750

4 LY-50KWSP 50 50 22,000-24,000 11690*1060*1750

5 LY-60KWSP 60 60 25,000-27,000 12860*1060*1750

6 LY-80KWSP 80 80 28,000-30,000 12680*1200*1750

7 LY-100KWSP 100 100 32,000-38,000 15200*1200*1750

8 LY-150KWSP 150 150 40,000-45,000 21050*1200*1750

9 LY-200KWSP 200 200 46,000-50,000 25050*1200*1750

Why Is PLC Industrial Microwave Date Drying Sterilizing Machine So Efficient?

Feature Of Industrial Microwave Dryer

1 High Quality Magnetrons Are Being Used

2 Pid Indicator/Controller For Easy To Understand And Operate User Control

3 Rf/Mw Choke/Timer Provision For Automatic Power Control

4 Stainless Steel Chamber Designed To Avoid Any Kind Of Radiations.

5 Required Electrical & Thermal Safety Features For Microwave Generator

6 Variable Frequency (Belt Speed Control)

7 Variable Power Output (Selectable) Up To 100%

8 Temperature Control

What Products Can The Industrial Microwave Dryer Machine Be Used For?

Microwave Dryer Machine Is Suitable For The Drying, Sterilization, De-Enzyme, Curing, And Puffing Of Various Kinds Of Food. Such As:

Wide Application Of Industrial Microwave Dryer:

1 Drying And Sterilization Of Meats: Chicken, Duck, Fish, Shrimp, Etc.

2 Drying And Serialization Of Various Fruits: Apple, Banana, Lemon, Kiwi, Etc.

3 Drying And Sterilization Of Various Vegetables: Carrots, Cabbage, Peas, Potato, Yam, Etc.

4 Puffing On Various Kinds Of Food: Potato Chips, Prawn Slices, Dried Fish, Etc.

5 Heating, Drying, And Sterilization Of Various Condiments.

6 De-Enzyme And Drying Of Various Flowers: Honeysuckle, Chrysanthemum, Rose, Peony, Etc.

7 Drying And Sterilization Of Various Oral Liquid, Medicinal Materials, Pills, Tablets, Powder, Etc.

8 Microwave Dryer Machine Is Suitable For The Thawing Of Various Quick-Frozen Food.

9 Microwave Dryer Machine Is Suitable For The Drying And Deodorization Of Soybean.

10 Drying And Curing Of Dried Fruit: Peanut, Pistachio Nut, Walnut, Chestnut, Hazelnut, Sunflower Seeds, Almond, Betel Nut, Olive, Etc.

What’s the Advantage of the PLC Industrial Microwave Date Drying Sterilizing Machine?

The Advantage Of The PLC Industrial Microwave Date Drying Sterilizing Machine:

1 Microwave Heating Process Is Clean.

2 Microwave Heat Penetrates Both On The Surface As Well As Internally Within The Object Placed For The Treatment.

3 High Speed Of Heating Reduces Total Time Of Processing.

4 Microwave Heating Process Is Highly Controllable

5 Spontaneous On/Off Control

How About The Loyal Cooperated Customers Of PLC Industrial Microwave Date Drying Sterilizing Machine?

Customers Who Buy Microwave Dryer Machine For Dates For The Second Time

1 Spain 300T/Year Stainless Steel Kunder Dates Drying Machine

2 1T/H Microwave Sterilization Equipment For Dates For Sale In Puerto Rico

3 1T/H PLC Industrial Microwave Date Drying Sterilizing Machine For Sale In Bolivia

4 Senegal 1T/H Continuous Microwave Oven For Dates

5 1T/H Microwave Commercially Microwave Dryer Machine Dried Dates For Sale In Côte d'Ivoire

6 1T/H Industrial Microwave Drying Dates Machine Sold In Russia

Cooperated Customer Request Engineer Installation Microwave Oven For Dates At 2021

7 100kg/H Industrial Drying Red Dates Sterilizing Machine For Sale In Uzbekistan Factory

8 100kg/h Industrial Automatic Microwave Dryer For Dates For Sale In Senegal Plant

9 Mozambique 1T/H Automatic Drying Red Dates Sterilizing Machine

10 Bangladesh 2t/h Industrial Automatic Continuous Industrial Microwave Dryer Sterilizer For Dates

11 1T/H Microwave Dryer For Dates Equipment

12 Uzbekistan 1T/H PLC Industrial Microwave Date Drying Sterilizing Machine Equipment

13 USA 1T/H Industrial Conveyor Belt Type Microwave Dryer Microwave Drying Machine For Dates

14 50kh/h Industrial Microwave Dryer For Dates For Sale In Nigeria Plant

Customers Who Purchase Continuous Microwave Dryer For Dates Through The Introduction Of Old Customers At 2021

15 Algerian Industrial Tunnel Type Date Microwave Dryer 300kg/h Production Line

16 Sudan 200kg/h Microwave Dryer Production Line For Dates

17 Moldova Small 200kg/h Microwave Dryer Equipment For Dates Drying

18 200kg/h Industrial Conveyor Belt Type Microwave Dryer Microwave Drying Machine For Dates Sold In Ukraine Agent

19 Nigeria 150Kg/H Industrial Tunnel Type Date Microwave Dryer

20 Austria Sells Industrial Microwave Oven For Dates 100kg/h

Cooperated Agent Of Plantain Microwave Herbal Drying Machine For Dates At 2021

21 Nigeria 150Kg/H Industrial Tunnel Microwave Drying Red Dates Sterilizing Machine

22 Dates Microwave Dryer For Sale In Pakistan 100kg/h

23 Austria Sells Industrial Microwave Dates Dryer Machine 100kg/h

24 500Kg/H Continuous Industrial Tunnel Type Date Microwave Dryer For Sale In Botswana Factory

25 Sudan 250kg/h PLC Industrial Microwave Date Drying Sterilizing Machine For Dates

26 Algerian Microwave Convection Dryer Dates Dryer 300kg/h

PLC Industrial Microwave Date Drying Sterilizing Machine Video