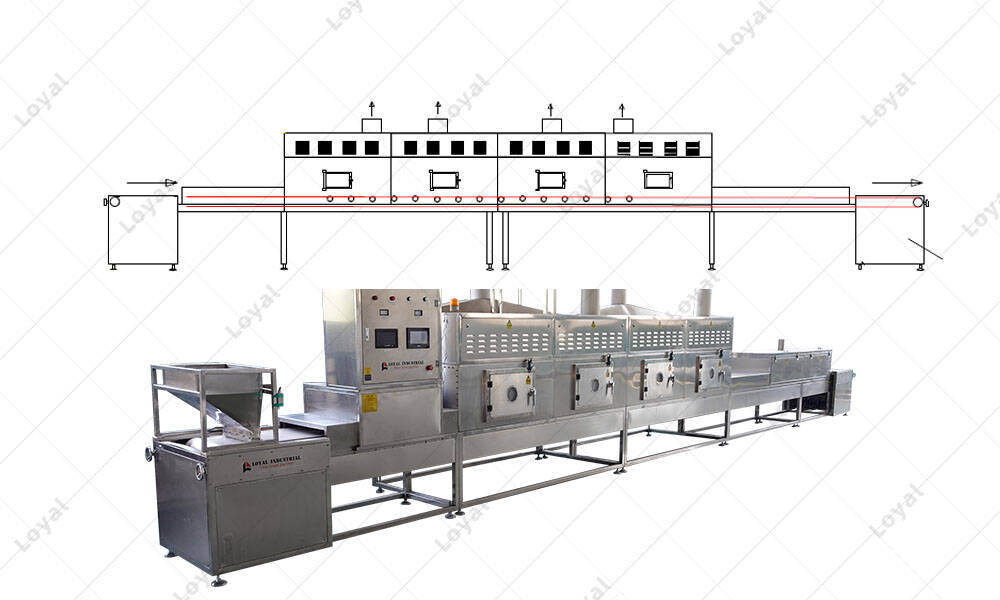

Tenebrio Mealworm Insect Microwave Drying Sterilization Machine

As one professional Tenebrio Mealworm Insect Microwave Drying Sterilization Machine manufacturer,we can offer small, medium and large Tenebrio Mealworm Insect Microwave Drying Sterilization Machin for sale. The Tenebrio Mealworm Insect Microwave Drying Sterilization equipment has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements. Tenebrio Mealworm Insect Microwave Drying Sterilization Machine uses microwave drying to treat Tenebrio molitor. Microwave dryers are widely used in fields such as Tenebrio molitor and silkworm drying. The microwave drying technology is mature and gradually replaces traditional drying equipment. It is the preferred machine for modern enterprises.

Tenebrio Mealworm Insect Microwave Drying Sterilization Machine Specifications :

Tenebrio Mealworm Insect Microwave Drying Sterilization Machine Detail Introduction :

As one professional Tenebrio Mealworm Insect Microwave Drying Sterilization Machine manufacturer,we can offer small, medium and large Tenebrio Mealworm Insect Microwave Drying Sterilization Machin for sale. The Tenebrio Mealworm Insect Microwave Drying Sterilization equipment has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements.

INTRODUCTION OF MAGGOTS CONVEYOR BELT MICROWAVE TUNNEL DRYER

Tenebrio Mealworm Insect Microwave Drying Sterilization Machine uses microwave drying to treat Tenebrio molitor. Microwave dryers are widely used in fields such as Tenebrio molitor and silkworm drying. The microwave drying technology is mature and gradually replaces traditional drying equipment. It is the preferred machine for modern enterprises. . In addition, the microwave dryer also has a sterilization function. Therefore, it can fully meet the deep processing requirements of Tenebrio molitor.

| The advantages of Tenebrio Mealworm Insect Microwave Drying Sterilization Machine | |

| 1. | The drying speed is fast, the aroma of the product is strong, uniform, and the color is bright. Selective heating. |

| 2. | The direction of water vapor in drying and dehydration is from the inside to the outside, so the Tenebrio molitor microwave dryer has a puffing effect, which is more helpful for the subsequent crushing. |

| 3. | Low-carbon environmental protection machinery and equipment, environmental protection, energy saving and high efficiency. |

| 4. | Conducive to control, excellent processing technology. |

| 5. | The Tenebrio molitor drying and sterilizing machine is used for low-temperature sterilization to ensure nutrients and traditional flavors. |

| 6. | Microwave Tenebrio sterilization and drying equipment has a small footprint, energy saving and environmental protection. |

HOW LONG DO DEHYDRATED MEALWORMS LAST?

Dried mealworms will last a very long time if stored without air circulation. Live mealworms will last many months; however, you need to keep them cool. Warm mealworms will mature quickly into pupae and then beetles. Keep them at around 40 degrees.

| Maggots Conveyor Belt Microwave Tunnel Dryer Equipment Parameters | ||

Equipment Model | LY-Microwave Drying Equipment | LY-Microwave Drying Equipment |

Rated Input Apparent Power | customization | customization |

Height of conveyor | 600-1000mm | 600-1000mm |

Inlet and outlet height | 40-100mm | 40-100mm |

Width of conveyor belt | 750±100mm(custom-made) | 1000±100mm(custom-made) |

Microwave leakage standard | ISO≤5mw/cm² | ISO≤5mw/cm² |

Operating frequency | 2450±50HMz | 2450±50HMz |

Transmission speed | 0~10m/min(Adjustable frequency) | 0~10m/min(Adjustable frequency) |

WHAT INDICATORS NEED TO BE REACHED FOR MAGGOTS CONVEYOR BELT MICROWAVE TUNNEL DRYER?

| Indicators Of Maggots Conveyor Belt Microwave Tunnel Dryer | |

| Expansion | If the puffing degree does not meet the requirements, the dried Tenebrio molitor cannot even meet the basic requirements of the outlet, and the ideal puffing degree requires the microwave cavity to have a high power density, which increases the difficulty of design and improves the The parameter requirements for the components are specified. |

| Finished color | The Tenebrio molitor from good microwave drying equipment should be yellow, or close to the color of the worm itself. The first requirement for designers is to understand the industry and have rich design experience, so that the processing technology of Tenebrio molitor can be improved. organically integrated into the design. |

| Dryness | Dryness is the last indicator, and its significance goes without saying. |

CUSTOMER PURCHASE CASE OF MAGGOTS CONVEYOR BELT MICROWAVE TUNNEL DRYER

| Customer cases for Mealworm Microwave Tunnel Drying Machine for factory in 2021 | |

| 1 | 1t/h cost of Maggots Conveyor Belt Microwave Tunnel Dryer sold in russia Factory |

| 2 | 1t/h Maggots Conveyor Belt Microwave Tunnel Dryer for sale in puerto rico Facotory |

| 3 | 1t/h Maggots Conveyor Belt Microwave Tunnel Dryer for sale in bolivia Palnt |

| 4 | Senegal 1t/h Mealworm Microwave Tunnel Drying Machine |

| 5 | 1t/h Mealworm Microwave Tunnel Drying Machine for sale in côte d'ivoire Agent |

| 6 | China 300t/year Mealworm Microwave Tunnel Drying Machine |

| Customer case of microwave drying equipment at 2021 | |

| 7 | 1t/h microwave drying equipment for factory in uzbekistan |

| 8 | 1000kg/h Maggots Conveyor Belt Microwave Tunnel Dryer for sale in senegal Agent |

| 9 | Mozambique 1t/h Microwave mealworm drying equipment |

| 10 | Bangladesh 2t/h Microwave mealworm drying equipment |

| Dealed customer have technology of microwave drying equipment at 2021 | |

| 11 | 1t/h thai microwave drying equipment for factory |

| 12 | Uzbekistan 1t/h Microwave mealworm drying equipment |

| 13 | Usa 1t/h microwave drying equipment |

| 14 | 800kg/h Microwave mealworm drying equipment for sale in Nigeria Plant |

| 15 | Microwave Insect Cricket Grasshopper Tenebrio Molitor Mealworm Superworm machine for sale in Singapore Plant |

| 16 | Industrial Microwave Black Soldier Fly Larva Bsfl Mealworm Drying Baking Oven Machine for sale in USA Factory |

| 17 | Black Soldier Fly Microwave Dryer Bsf Insects Larvae Drying Equipment for sale in Israel Plant |

| 18 | Tunnel Tenebrio Molitor Microwave Drying Sterilization Machine for sale in Mexico Factory |

| 19 | Black Soldier Fly Larvae Mealworm Insect Microwave Drying Sterilization Machine for sale in Malaysia |

| 20 | Insects Dried Tenebrio Molitor Microwave Machine for sale in Netherlands Agent |

| 21 | Microwave Mealworm Larva Black Soldier Fly Locust Dryer for sale in Portugal Agent |