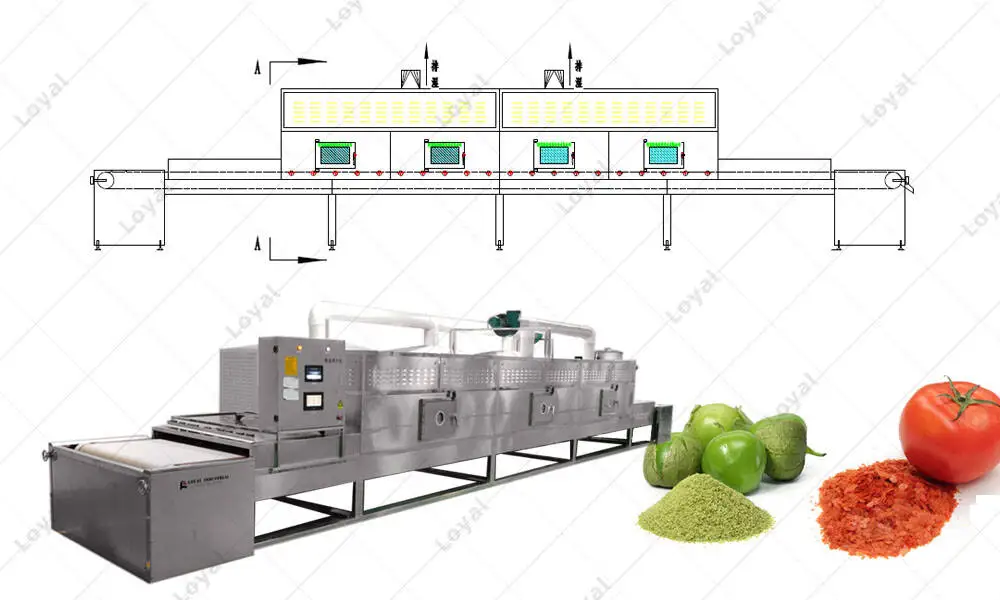

High Quality Continuous Dehydrated Vegetables Powder Microwave Sterilization Machine

As one professional continuous dehydrated vegetables powder microwave sterilization machine manufacturer,we can offer small, medium and large dehydrated vegetables powder microwave sterilization machine for sale. The fruit and vegetable powder microwave sterilization machine has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements.

Vegetable powder microwave drying equipment can dry and dehydrate fresh vegetables. Vegetable powder is made by air-drying or drying fresh vegetables, and then crushing them into powder. With the improvement of people's living standards, vegetable powder as a new food variety is welcomed by people because of its rich nutrition.

High Quality Continuous Dehydrated Vegetables Powder Microwave Sterilization Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | LOYAL Microwave Sterilization Machine |

| Model Number | Continuous Dehydrated Vegetables Powder Microwave Sterilization Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Sterilization Machine |

| Payment Terms | L/C,D/A,D/P,T/T, |

| Supply Ability | 25Days of Microwave Sterilization Machine |

| Delivery Detail | 20days--35days |

| Packaging Details | Export-compliant microwave equipment packaging |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sales Team | Professional microwave technology team |

| Honor | A Number Of National Microwave Equipment Patents |

| Technology | 8 Years Of Microwave Technology |

High Quality Continuous Dehydrated Vegetables Powder Microwave Sterilization Machine Detail Introduction :

As one professional continuous dehydrated vegetables powder microwave sterilization machine manufacturer,we can offer small, medium and large dehydrated vegetables powder microwave sterilization machine for sale. The fruit and vegetable powder microwave sterilization machine has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements.

Vegetable powder microwave drying equipment can dry and dehydrate fresh vegetables. Vegetable powder is made by air-drying or drying fresh vegetables, and then crushing them into powder. With the improvement of people's living standards, vegetable powder as a new food variety is welcomed by people because of its rich nutrition. Vegetables are rich in nutrients, composed of vitamins, minerals and dietary fibers, which can maintain a certain amount of nutrients after being ground into powder.

WHAT ARE THE ADVANTAGE OF CONTINUOUS DEHYDRATED VEGETABLES POWDER MICROWAVE STERILIZATION MACHINE ?

Advantages Of Fruit And Vegetable Powder Process Of Sterilization | |

1 | Whole body made of stainless steel to meet the food safety standards, long service life. |

2 | Uniform heating. Microwave penetrates to the core of the product and heats every part evenly. |

3 | Increasing products quality. The vegetable materials will have more vivid color after microwave treatments. |

4 | Safe and reliable. The equipment only consumes electric energy, with no pollution to the environment and materials, which meets the environmental protection requirements. |

5 | Improving working condition. The PLC touch screen controlling system and human-computer interface operation have greatly enhance the working efficiency. |

6 | Practical, large capacity, high efficiency, energy and cost saving. The energy and cost can save more than 30%. |

HOW MANY KINDS OF DEHYDRATED VEGETABLES POWDER CAN BE DRIED AND STERILIZED BY THIS MICROWAVE STERILIZATION SYSTEMS

Application Of Fruit And Vegetable Powder Sterilization | |

| 1. | Widely applied in the drying and sterilizing of various seasonal root vegetables with low moisture, like sliced carrots/cabbage/peas/potato/pumpkin/onion/Chinese yam/ginger/radish , etc. |

| 2. | Suitable for vegetable drying and sterilizing of supermarket, large vegetable garden, vegetable planting farms, etc. |

TECHNICAL PARAMETER OF CONTINUOUS DEHYDRATED VEGETABLES POWDER MICROWAVE STERILIZATION MACHINE

Technical Parameter Of Continuous Dehydrated Vegetables Powder Microwave Sterilization Machine | ||||

Model | Power | Dehydration Capacity | Sterilization Capacity | Size |

LY-12KW | 12KW | 12kg/h | 120-150kg/h | 7*0.84*1.75m |

LY-20KW | 20KW | 20kg/h | 192-240kg/h | 9.4*0.84*1.75m |

LY-30KW | 30KW | 30kg/h | 300-375kg/h | 11.7*0.84*1.75m |

LY-40KW | 40KW | 40kg/h | 396-495kg/h | 10.52*1.06*1.75m |

LY-50KW | 50KW | 50kg/h | 504-630kg/h | 11.7*1.06*1.75m |

WHICH MARKET DID THE LOYALSMALL SCALE CONTINUOUS DEHYDRATED VEGETABLES POWDER MICROWAVE STERILIZATION MACHINE SOLD?

LOYAL's share of fruit and vegetable powder microwave sterilization machine exported to international markets has steadily increased. According to the export goods trade data in 2021, Loyal's export market share in the international market is 86.5%, of which the vegetable and fruit powder microwave drying equipment export market share is 20.8%, the export market share in the Americas is 30.2%, and the export market share in Asia is 35.5%. If you are interested in a meat dryer, please contact us today, we offer you the most cost-effective turnkey solution.

Customer Have Formula Request Of Dehydrated Vegetables Powder Continuous Microwave Oven | |

1 | China 300t/Year Industrial Microwave Dehydrated Vegetables Powder Tunnel Dryer |

2 | 1T/H Dehydrated Vegetables Powder Microwave Dryer For Sale In Puerto Rico Factory |

3 | 1T/H Dehydrated Vegetables Powder Microwave Dryer For Sale In Bolivia Plant |

4 | 800Kg/H Automatic Microwave Dehydrated Vegetables Powder Dryer For Sale In Argentina |

5 | 2T/H Automatic Microwave Dehydrated Vegetables Powder Dryer For Sale In Benin Factory |

6 | 2T/H PLC Control Dehydrated Vegetables Powder Automatic Microwave Drying Machine For Sale In British Indian Ocean Territory |

7 | 2T/H PLC Control Dehydrated Vegetables Powder Automatic Microwave Drying Machine For Sale In Chile Agent |

Cooperated Customer For Laboratory Machine Of Automatic Microwave Dehydrated Vegetables Powder Dryer | |

1 | Senegal 200Kg/H Industrial PLC Control Dehydrated Vegetables Powder Automatic Microwave Drying Machine |

2 | 100-200Kg/H PLC Control Dehydrated Vegetables Powder Automatic Microwave Drying Machine For Sale In Côte d'Ivoire Agent |

3 | 300-400Kg/H Automatic Microwave Dehydrated Vegetables Powder Dryer For Sale In Sold In Russia |

4 | 500Kg/H Automatic Microwave Dehydrated Vegetables Powder Dryer For Sale In Sold In Denmark Plant |

5 | 600Kg/H Automatic Microwave Dehydrated Vegetables Powder Dryer For Sale In Dominica Factory |

6 | 100-200Kg/H PLC Control Dehydrated Vegetables Powder Automatic Microwave Drying Machine For Sale In Egypt |

7 | 300-400Kg/H Automatic Microwave Dehydrated Vegetables Powder Dryer For Sale In Sold In Ethiopia Plant |

Cooperated Customer Request Engineer Installation At 2021 | |

1 | 1T/H Factory Direct Sale Industrial Tunnel Microwave Dehydrated Vegetables Powder Drying Machine For Sale In Uzbekistan |

2 | 1000kg/h Industrial Automatic Microwave Dehydrated Vegetables Powder Dryer For Sale In Senegal Plant |

3 | Mozambique 1T/H Automatic Microwave Dehydrated Vegetables Powder Dryer Machine |

4 | 1T/H Thai Automatic Microwave Dehydrated Vegetables Powder Drying Machine |

5 | Uzbekistan 1T/H Automatic Microwave Dehydrated Vegetables Powder Drying Machine |

6 | 2T/H Factory Direct Sale Industrial Tunnel Microwave Dehydrated Vegetables Powder Drying Machine For Sale In Germany Plant |

7 | 2T/H Factory Direct Sale Industrial Tunnel Microwave Dehydrated Vegetables Powder Drying Machine For Sale In Guinea Factory |

Cooperated Customer With Microwave Dryer Machine For Dehydrated Vegetables Powder Technology At 2021 | |

1 | Nigeria 500Kg/H Microwave Dryer Machine For Dehydrated Vegetables Powder |

2 | Austria Sells Microwave Dryer Machine For Dehydrated Vegetables Powder 1000kg/h |

3 | Microwave Dryer Machine For Waste Water Dehydrated Vegetables Powder For Sale In Pakistan 1000kg/h |

4 | 1T/H Microwave Dryer Machine For Dehydrated Vegetables Powder For Sale In India Factory |

5 | 2T/H Microwave Dryer Machine For Dehydrated Vegetables Powder For Sale In Israel Palnt |

6 | 2T/H Microwave Dryer Machine For Dehydrated Vegetables Powder For Sale In Jamaica Plant |

7 | 2T/H Microwave Dryer Machine For Dehydrated Vegetables Powder For Sale In Morocco Agnet |