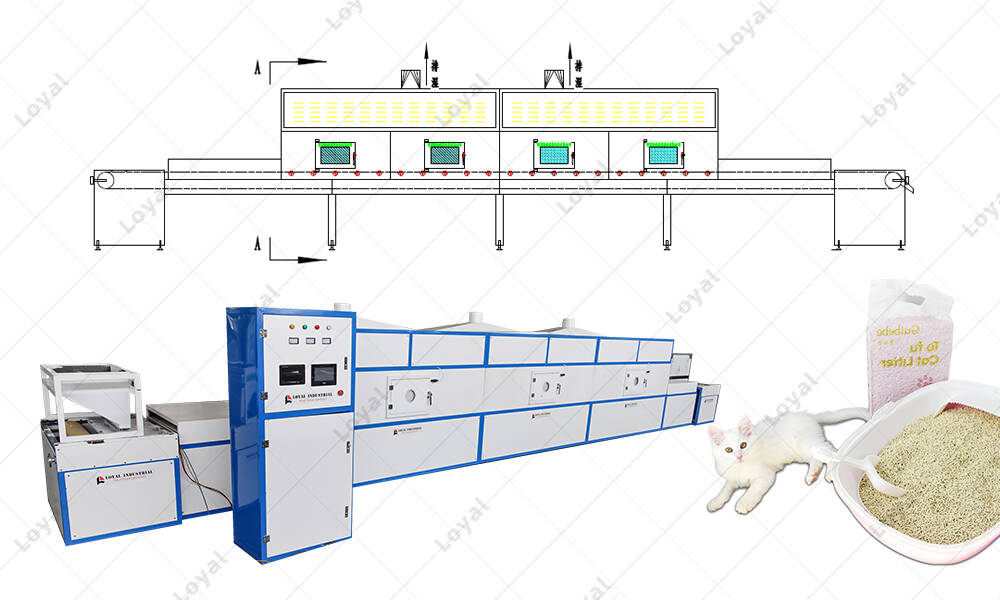

Automatic Industrial Tunnel Tofu Crystal Cats Litter Microwave Sterilizing Drying Machine

Tunnel conveyor belt type automatic industrial tunnel crystal cats litter

tofu crystal cats litter microwave sterilizing drying machine is a new drying method. When drying, the microwave energy directly acts on the medium molecules and converts it into heat energy. Due to the penetrating property of the microwave, the medium can be heated at the same time without heat conduction, so the heating speed is very fast, and the drying speed can be shortened for foods with a water content below 30%. It only takes 3~6 minutes to complete the drying of crystal cat litte, no rolling friction, and the drying temperature is only 45 degrees to 65 degrees. Crystal cats litter handles water well and forms spheres easily.

Automatic Industrial Tunnel Tofu Crystal Cats Litter Microwave Sterilizing Drying Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Tunnel Conveyor Belt Type Automatic Industrial Tunnel Crystal Cats Litter Tofu Crystal Cats Litter Microwave Sterilizing Drying Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Drying Sterilizing Machine |

| Delivery Detail | 20days/Microwave equipment assembly completed |

| Packaging Details | Export-compliance microwave equipment packaging |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sale Team | Professional microwave technology team |

| Honor | A Number Of National Microwave Equipment Patents |

| Technology | 8 Years Of Microwave Technology |

Automatic Industrial Tunnel Tofu Crystal Cats Litter Microwave Sterilizing Drying Machine Detail Introduction :

tofu crystal cats litter microwave sterilizing drying machine is a new drying method. When drying, the microwave energy directly acts on the medium molecules and converts it into heat energy. Due to the penetrating property of the microwave, the medium can be heated at the same time without heat conduction, so the heating speed is very fast, and the drying speed can be shortened for foods with a water content below 30%. Hundreds of times.

Introduction Of Crystal Cats Litter Microwave Drying Sterilizing Machine

Tofu crystal cats litter is generally made of tofu dregs and tofu fiber. A good tofu crystal cats litter is not only better in terms of deodorization, water absorption, and agglomeration, but also safer because the ingredients are mainly tofu dregs. It's okay to eat occasionally.the microwave tofu crystal cats litter dryer of shandong loyal equipment co., ltd. Is a new type of tofu crystal cats litter drying equipment designed according to the characteristics of tofu crystal cats litter and the principle of microwave heating and drying. Microwave drying is different from traditional drying equipment. Microwave drying also has a sterilization function.

How Long Does It Take To Dry a tidy cats litter?

It only takes 3~6 minutes to complete the drying of crystal cat litte, no rolling friction, and the drying temperature is only 45 degrees to 65 degrees. Crystal cats litter handles water well and forms spheres easily.

Parameters Of Microwave Tofu Crystal Cats Litter Drying Sterilizing Equipment Dryer Machine

| Crystal cats litter microwave drying sterilizing machine | |

| 1. Model | Ly-100 |

| 2. Input power | 380v/50hz, three-phase (customized) |

| 3. Microwave input power | 100kw (customized) |

| 4. Microwave frequency | 2450mhz±50hz |

| 5. Rated input power | ≤120kva |

| 6. Height | 80mm |

| 7. Belt width | 800mm (customized) |

| 8. Belt speed | 0.5~10m/min |

| 9. Dimensions (l×w×h) | 17000×1000×1650mm (customized) |

| 10. Working environment | Working temperature 0~40℃, relative humidity≤80% |

| 11. Microwave drying capacity | Dehydration 100kg per hour (customized) |

| 12. Control method | Plc touch screen |

Why We Would Choose Microwave Drying Tofu Crystal Cats Litter?

| Cat Litter Microwave Drying Sterilizing Machine | |

| Traditional crystal cats litter dryer | Microwave crystal cats litter drying sterilizing equipment dryer machine |

| The traditional crystal cats litter dryer is a tumble dryer, which cannot keep the original shape of the crystal cats litter and is easy to damage the size and color of the crystal cats litter. | With a microwave dryer, the water in the crystal cats litter is handled well and spheres are easily formed. |

| Large area, easy to cause waste | The crystal cats litter dryer occupies a small area, is safe and environmentally friendly |

| Low yield and uneven heating | The industrial microwave dryer heats evenly and improves product quality |

| Long heating time, takes 6 hours | Small thermal inertia, instant heating, drying can be completed in 3~6 minutes |

How Do You Dry Flowers In The Microwave With Crystal Cats Litter?

Continuous microwave oven is a multifunctional continuous microwave dryer, microwave tunnel dryer can be used for drying roses and flowers at the same time. For the drying of some mosaic materials, these materials have a large moisture content and their properties are not very stable, so they need to be dehumidified quickly to avoid changes in color or internal components in the external environment for a long time. In order to ensure the appearance and quality of the dried flower, the whole drying process needs to be carried out in an industrial microwave dryer at a low temperature, and the temperature setting range is 45℃~65℃.

Applications Of Microwave Tofu crystal cats litter Drying Sterilizing Equipment Dryer Machine:

| Microwave drying dehydration machine for crystal cats litter production line | |

| 1. Microwave drying | Tenebrio molitor microwave drying machine, paper tray drying machine, bread crumb drying equipment, crystal cats litter drying, insect drying equipment, traditional chinese medicine extract drying machine, microwave drying machine for black soldier flies, microwave drying machine for thermal insulation board, rope drying, yarn drying equipment, fly maggot microwave drying, glass fiber drying, epoxy curing, cotton drying |

| 2. Microwave baking | Low-temperature roasting of whole grains, soybean curing, red bean and barley flour roasting machine, millet microwave roasting, oatmeal microwave roasting equipment, pumpkin seed roasting, sunflower seed roasting, mung bean roasting, walnut microwave roasting, almond opening roasting |

| 3. Microwave fixing | Microwave tea greening, rose greening equipment, dandelion greening machine, mulberry leaf greening machine, honeysuckle greening equipment, chrysanthemum greening equipment, wheat seedlings greening, highland barley seedlings greening |

| 4.Microwave sterilization | Microwave spice sterilization, flour microwave sterilization, microwave nutritional powder sterilization, microwave nut insecticide, wheat germ sterilization, microwave chili powder sterilization, nutrient powder microwave sterilization, walnut powder sterilization equipment, lotus root starch sterilization |

| 5.Microwave heating equipment | Microwave lunch box heating |

| 6. Microwave baking | Microwave prawn roasting machine, microwave small fish roasting machine, prawn roasting machine manufacturers |

| 7. Microwave drying | Bread crumb dryer, honeysuckle drying, tobacco leaf drying equipment, tobacco puffing, powder puff drying equipment, water retaining agent drying equipment, monocrystalline silicon drying equipment |

| 8. Microwave drying of lithium carbonate | Insulation board drying equipment, perlite board drying, calcium chloride dihydrate drying, barium hydroxide drying, starch drying, paper tube drying, industrial salt drying, glass fiber drying, epoxy resin drying |

| 9. Microwave thawing | Meat microwave thawing equipment, microwave beef thawing equipment, microwave prawn thawing equipment, chicken microwave thawing equipment, duck microwave thawing equipment, lamb microwave thawing equipment, frozen meat thawing equipment, microwave seafood thawing equipment, beef microwave slow thawing machine, tunnel microwave frozen mutton thawing equipment, microwave thawing fruit, microwave thawing chicken breast, fruit thawing machine |

| 10. Microwave puffing | Shrimp slices puffing equipment, pork skin puffing, dried tofu puffing, puffing of bean skin |

Customer Cases For Microwave Drying Dehydration Machine for crystal cats litter Production Line For Factory In 2021

Shandong Loyal Industrial relies on complete product specifications, excellent product quality and professional services. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company's products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world. If you are interested in the Microwave Drying Dehydration Machine for crystal cats litter Production Line, please contact LOYAL immediately, we will provide you with high-quality formulations of tidy cats litter drying, professional technical process guidance, and a full range of professional market analysis.

Customer Cases For Microwave Drying Dehydration Machine for crystal cats litter Production Line For Factory In 2021 | |

| 1 | 1t/h Ce Certificated Industrial Energy Efficient Microwave Drying Dehydration Machine for crystal cats litter Production Line Sold In Russia Factory |

| 2 | 1t/h Industrial Microwave crystal cats litter Drying Machine Fish Feed Dehydrator Dog Food Dryer Tunnel Machine For Sale In Puerto Rico Factory |

| 3 | 1t/h Industrial Microwave crystal cats litter Drying Machine Fish Feed Dehydrator Dog Food Dryer Tunnel Machine For Sale In Bolivia Agent |

| 4 | Senegal 1t/h Industrial Microwave crystal cats litter Drying Machine Fish Feed Dehydrator Dog Food Dryer Tunnel Machine |

| 5 | 1t/h Energy Saving Large Industrial Microwave Food Dehydrator Fish Shrimp Dehydration Microwave Dryer For Sale In Côte d'Ivoire Plant |

| 6 | China 300t/Year Pet Food Microwave Drying and Sterilization Machine crystal cats litter Dryer Equipment |

Customer Case Of High Quality Industrial Tunnel Microwave Rice Corn Green Cocoa Beans Drying Machine From Phenix Machinery At 2021 | |

| 1 | 1t/h Industrial Tunnel Belt Conveyor Microwave Paper Powder Tea Herbs Leaves Nut Spice Grain Sterilization Dryer Drying Machine In Uzbekistan |

| 2 | 1000kg/h Pet Food Microwave Drying and Sterilization Machine crystal cats litter Dryer Equipment For Sale In Senegal |

| 3 | Mozambique 1t/h Fully Pet Food Microwave Drying and Sterilization Machine crystal cats litter Dryer Equipment |

| 4 | Bangladesh 2t/h Fully Industrial Microwave crystal cats litter Drying Machine Fish Feed Dehydrator Dog Food Dryer Tunnel Machine |

| 5 | 1t/h Thai Industrial Microwave Oven Roasted Hazelnut Sterilization Machine |

| 6 | Uzbekistan 1t/Htunnel Microwave Wheat Rice Powder Flour Drying Sterilization Sterilizer Machine |

| 7 | Usa 1t/h Industrial Microwave crystal cats litter Drying Machine Fish Feed Dehydrator Dog Food Dryer Tunnel Machine |

| 8 | 800kg/h Indian Spice Microwave Garam Masala Sterilizer Machine Black Pepper Drying And Sterilizing Machine |

| 9 | Dealed Customer Have Technology Of Industrial Microwave crystal cats litter Drying Machine Fish Feed Dehydrator Dog Food Dryer Tunnel Machine At 2021 |

2021Customer Case Of Pay By T/T For China Microwave Tofu crystal cats litter Drying Sterilizing Equipment Dryer Machine From Phenix Machinery | |

| 1 | 1t/h Industrial China Microwave Tofu crystal cats litter Drying Sterilizing Equipment Dryer Machine In Afghanistan |

| 2 | 1000kg/h Industrial Microwave crystal cats litter Drying Machine Fish Feed Dehydrator Dog Food Dryer Tunnel Machine For Sale In Anguilla |

| 3 | Bahrain 1t/h Fully Tunnel Microwave crystal cats litter Drying Machine |

| 4 | Bangladesh Factory 2t/h Fully Tunnel Microwave crystal cats litter Drying Machine |

| 5 | 1t/h Bouvet Islands Industrial Microwave Oven Roasted Hazelnut Sterilization Machine |

| 6 | Central African Republic 1t/H Microwave Tofu crystal cats litter Drying Sterilizing Equipment Dryer Machine |

| 7 | Colombia Plant 1t/h Microwave Tofu crystal cats litter Drying Sterilizing Equipment Dryer Machine |

| 8 | 800kg/h Eritrea Spice Industrial Microwave crystal cats litter Drying Machine Fish Feed Dehydrator Dog Food Dryer Tunnel Machine |

| 9 | Gambia Customer Have Technology Of Full Automatic NMicrowave Tofu crystal cats litter Drying Sterilizing Equipment Dryer Machine Microwave Drying Dehydration Machine for Cat Litter Production Line At 2021 |