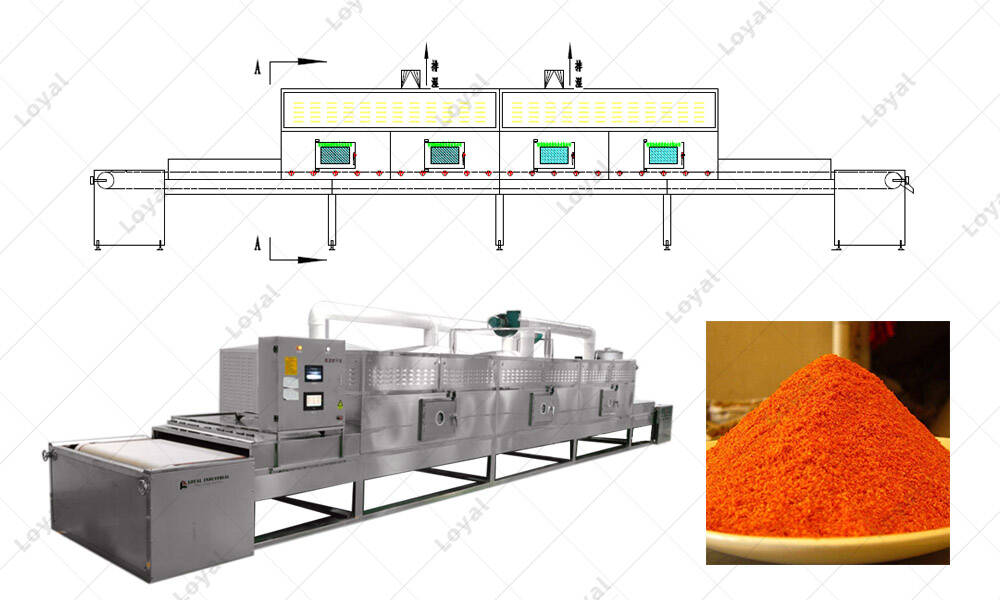

Continuous Paprika Powder Microwave Sterilization Drying Machine

As a manufacturer of chili powder drying and sterilizing machine, our microwave tunnel chili powder drying equipment uses electricity or steam as energy, and uses magnetrons to convert electrical energy into microwaves to directly heat materials without shrinking. Smoked paprika tunnel dryer adopts microwave drying paprika powder process for drying, which is a new type of drying technology equipment. The advantages of microwave drying paprika powder are fast drying and good quality. Shandong Loyal's paprika powder microwave dryer has become the first choice of many paprika powder customers. The tunnel type chili powder microwave drying equipment can directly dry the crushed chili sauce into chili powder, and the chili powder tunnel microwave sterilization drying machine can also directly add a cooling device, to achieve better drying effect.

Continuous Paprika Powder Microwave Sterilization Drying Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Continuous Paprika Powder Microwave Sterilization Drying Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Delivery Detail | 20days/Microwave equipment assembly completed |

| Packaging Details | Export-compliance microwave equipment packaging |

| Team | Professional microwave technology team |

| Sale Team | Microwave Drying Sterilizing Machine Technical Team |

| Honor | A number of national microwave equipment patents |

| Process | Ten years of microwave equipment manufacturing process |

| Technology | 8 years of microwave technology |

Continuous Paprika Powder Microwave Sterilization Drying Machine Detail Introduction :

As a manufacturer of chili powder drying and sterilizing machine, our microwave tunnel chili powder drying equipment uses electricity or steam as energy, and uses magnetrons to convert electrical energy into microwaves to directly heat materials without shrinking. Smoked paprika tunnel dryer adopts microwave drying paprika powder process for drying, which is a new type of drying technology equipment. The advantages of microwave drying paprika powder are fast drying and good quality. Shandong Loyal's paprika powder microwave dryer has become the first choice of many paprika powder customers.

Introduction Of Continuous Microwave Chili Powder Sterilization Drying Machine

The fresh chili is crushed and ground into chili sauce or powder. The tunnel type chili powder microwave drying equipment can directly dry the crushed chili sauce into chili powder, and the chili powder tunnel microwave sterilization drying machine can also directly add a cooling device, to achieve better drying effect. In addition, Shandong Loyal can be customized according to your needs. The dried chili powder is cooled, weighed and packaged, and a complete chili powder production line can be completed.

What Is Technical Parameter Of Industrial Microwave Paprika Powder Dryer For Sale?

Technical Parameter Of Industrial Microwave Paprika Powder Sterilization Machine | |||||

Model | Dehydrated | Input Power | Size | Microwave Output | Sterilization |

LY-12 | 12kg/hr | 18kw | 7200x650x1800mm | 12kw | 100-150kg/hr |

LY-15 | 15kg/hr | 20kw | 8300x720x1800mm | 15kw | 120-180 kg/hr |

LY-20 | 20kg/hr | 26kw | 8500x750x1800mm | 20kw | 180-250 kg/hr |

LY-30 | 30kg/hr | 36kw | 10500x950x2000mm | 30kw | 280-350 kg/hr |

LY-40 | 40kg/hr | 46kw | 10500x1050x2000mm | 40kw | 380-450 kg/hr |

LY-50 | 50kg/hr | 58kw | 12200x1200x2000mm | 50kw | 480-550 kg/hr |

How Is Advantages Of Industrial Microwave Chili Paprika Tunnel Dryer?

Compared with the traditional chili powder dryer, our paprika powder microwave dryer has more advantages.

Advantages Of Chili Powder Microwave Dryer | ||

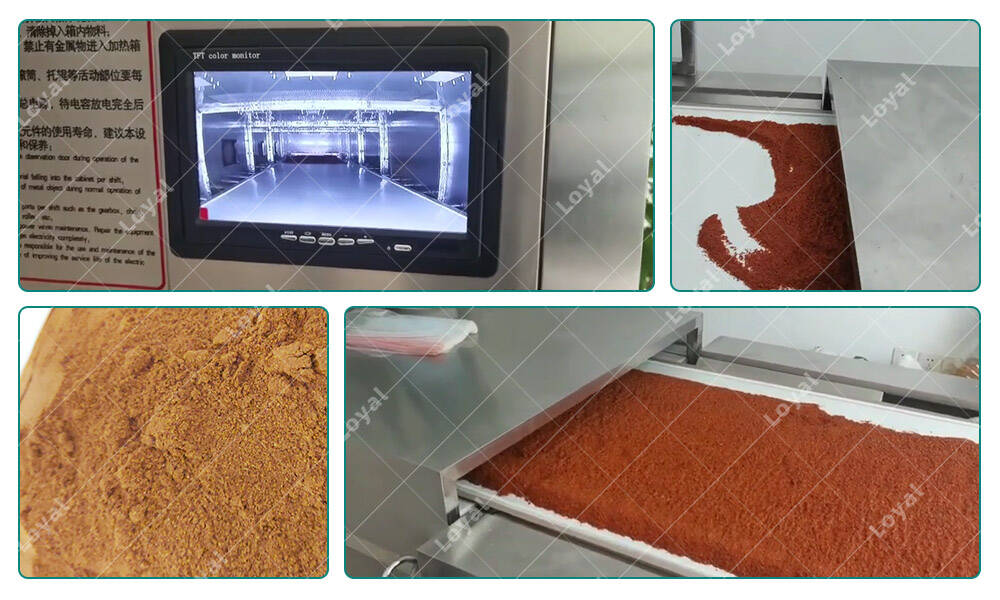

1 | Selective heating. | Using chili powder tunnel microwave sterilization drying machine, uniform heating and uniform drying can be achieved, and the heating treatment is transparent and the effect is thorough. |

2 | Low energy consumption and high efficiency. | The microwave directly acts on the material, so there is no additional heat loss, the thermal efficiency is high, and the production environment is also significantly improved. Compared with far-infrared heating, paprika powder microwave sterilization drying machine can save 30% of electricity. |

3 | The time is short and the speed is fast. | Microwave heating is a process in which the heated object itself becomes a heating body without heat conduction. The object can be heated uniformly in a short time, and the drying time is shortened. |

4 | Easy to control and advanced technology. | Compared with the conventional method, the equipment is ready to use; there is no thermal inertia, and the operation is flexible and convenient; the microwave power is adjustable, and the transmission speed is adjustable. In microwave heating and drying, there is no waste water and no waste gas.Microwave drying paprika powder process is a safe and harmless high-tech. |

How About the Application Of Continuous Microwave Paprika Powder Drying Machine?

Chili powder microwave drying and sterilization equipment is mainly used for salty condiments, sweet condiments, bitter condiments, spicy condiments (chili, pepper, mustard, etc.); sour condiments (vinegar, tomato juice, hawthorn sauce, etc.) ), umami condiments (monosodium glutamate, chicken essence, shrimp oil, fish sauce, oyster sauce, etc.), flavor condiments (prickly ash, star anise, cooking wine, onion, garlic, etc.) drying, drying and sterilization.And the industrial microwave paprika powder drying machine also can be used in drying and sterilizing all kinds of paper products,gray cardboard,paper,cardboard boxes,paper pulp,honeycomb paperboard,pulp model etc.

Application Of Industrial Sweet Paprika Drying Equipment | |

1 | All kinds of teas,herbs, flowers, green leaves,etc. |

2 | Gel-like materials, such as silicone, rubber and latex, etc. |

3 | Agricultural products,such as china date,nuts,grains,peanut,etc. |

4 | Various dried meat, like beef, pork, chicken,duck, fish etc. |

5 | Powder for various material,such as spices, spicy condiments and other food additives. |

6 | Insects such as locusts, locusts, earthworms, black soldier fly larvae, centipedes, scorpions. |

7 | Chemical material,medicine tablet or pill,such as watered pills,water-honey bolus,honeyed bolus,etc. |

Which Market Did The Loyal Continuous Microwave Sweet Paprika Dehydration Machine?

Customer Case Of Continuous Sweet Paprika Tunnel Dryer At 2021 | |

1 | 500kg/h Thai industrial paprika powder belt dryer for Thailand customer |

2 | 3000kg/h large scale industrial sweet paprika drying equipment for sale in Uzbekistan Plant |

3 | 1500kg/h automatic chili paprika drying equipment for sale in Nigeria Agent |

4 | 600kg/h microwave sweet paprika drying equipment for factory in Canada Factory |

5 | 1000kg/h industrial microwave paprika powder drying equipment for sale in Japan Plant |

6 | English 1000kg/h fully automatic chili paprika microwave drying equipment |

7 | Bangladesh 2000kg/h fully automatic sweet paprika microwave drying equipment |

Customer Case Of Continuous Industrial Chili Powder Dryer At 2021 | |

1 | Continuous industrial paprika powder drying equipment fully automatic 500kg/h in Algerian |

2 | 800kg/h industrial automatic industrial chili paprika belt dryer for sale in Senegal Plant |

3 | 1000kg/h industrial drying paprika powder equipment in pharmaceutical industry sold in Russia |

4 | 1000kg/h cost of paprika powder microwave drying equipment sold in Japan Factory |

5 | 2000kg/h industrial sweet paprika microwave price for factory for sale in Egypt Plant |

6 | 1000kg/h industrial microwave chili paprika price for sale in Bolivia Agent |

7 | Senegal 1000kg/h industrial fully automatic paprika powder industrial sized microwave |

Customer Case Of Industrial Paprika Powder Sterilization Drying Equipment At 2021 | |

1 | 1500kg/h industrial chili paprika drying equipment and systems for sale in Bolivia Plant |

2 | Mozambique 1500kg/h industrial paprika powder drying equipment |

3 | 1300kg/h industrial continuous sweet paprika belt dryer for sale in Brazil Agent |

4 | 1500kg/h Thai microwave red chili paprika drying equipment for factory |

5 | Egypt 1000kg/h fully automatic industrial sweet paprika microwave price |

6 | USA 1200kg/h microwave paprika powder drying equipment |

7 | 800kg/h industrial microwave red paprika powder drying equipment for sale in Japan |