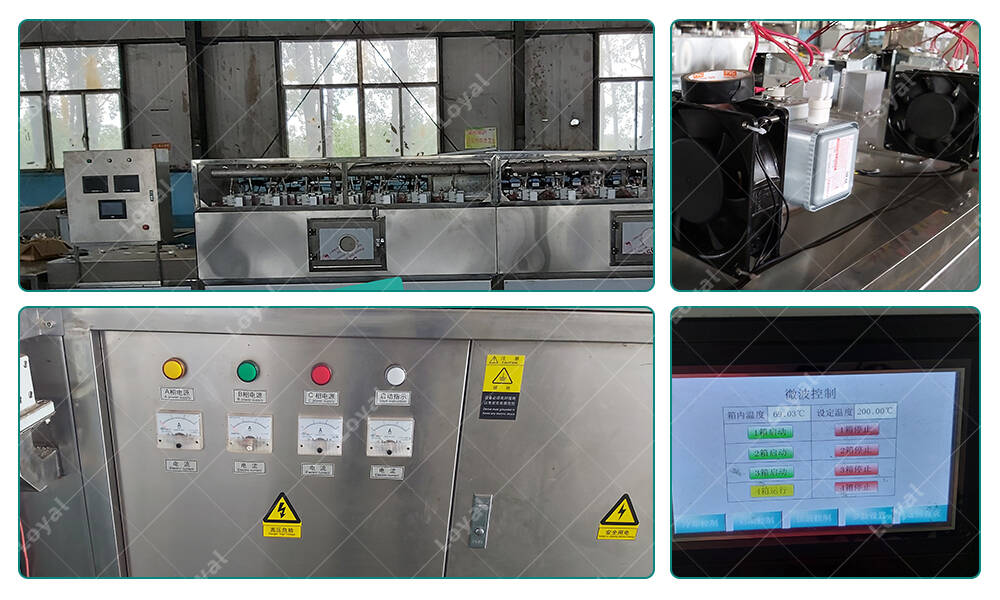

Industrial Tunnel Microwave Food Power Drying Sterilization Machine

As one professional Industrial Tunnel Microwave Food Power Drying Sterilization Machine manufacturer,we can offer small, medium and large microwave drying and sterilization equipment drying machine for sale. Microwave heating is the overall heating, that is, heating, the internal and external heating of the material, not the heat of the traditional heating method is conducted from the surface layer of the material.Fast, efficient, safe and environmentally friendly.

Cereal flour, flour (rice, rice flour, jelly, glutinous rice balls, rice cakes, oatmeal, bread, steamed buns, steamed buns, dumpling wrappers, wonton wrappers, noodles, pancakes, steamed dumplings, corn, cakes, biscuits, mala cakes, phoenix cakes , carrot cake, taro cake....)

Root and tuber powders (potato, taro, sweet potato, lotus root...)

Bean powder (pea, mung bean, red bean....)

Fruits high in starch (bananas, plantains, dates, peaches...)

High-calorie fruits: melons, durians, lychees, longan...powder

Industrial Tunnel Microwave Food Power Drying Sterilization Machine Specifications :

| Price | Check with Industrial Tunnel Microwave Food Power Drying Sterilization Machine Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Industrial Microwave Food Power Drying Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

Industrial Tunnel Microwave Food Power Drying Sterilization Machine Detail Introduction :

As one professional Industrial Tunnel Microwave Food Power Drying Sterilization Machine manufacturer,we can offer small, medium and large microwave drying and sterilization equipment drying machine for sale.

Cereal flour, flour (rice, rice flour, jelly, glutinous rice balls, rice cakes, oatmeal, bread, steamed buns, steamed buns, dumpling wrappers, wonton wrappers, noodles, pancakes, steamed dumplings, corn, cakes, biscuits, mala cakes, phoenix cakes , carrot cake, taro cake....)

Root and tuber powders (potato, taro, sweet potato, lotus root...)

Bean powder (pea, mung bean, red bean....)

Fruits high in starch (bananas, plantains, dates, peaches...)

High-calorie fruits: melons, durians, lychees, longan...powder

The so-called starchy foods mainly refer to carbohydrate-rich foods and root vegetables. Foods rich in carbohydrates include rice powder, wheat powder, corn powder, etc., and root vegetables include potato powder, potato powder, yam powder, etc. In addition, starchy fruits such as various beans and bananas are also included in starchy foods.

The Industrial Tunnel Microwave Food Power Drying Sterilization Machine has reasonable price, reliable quality and professional service!Our company provides customers full set service .cost accounting,Industrial Tunnel Microwave Food Power Drying Sterilization Machinee design, microwave cocoa powder drying and sterilizing machine recipes, machine installation and debugging, design Industrial Tunnel Microwave Food Power Drying Sterilization Machine request according to customer requirements.

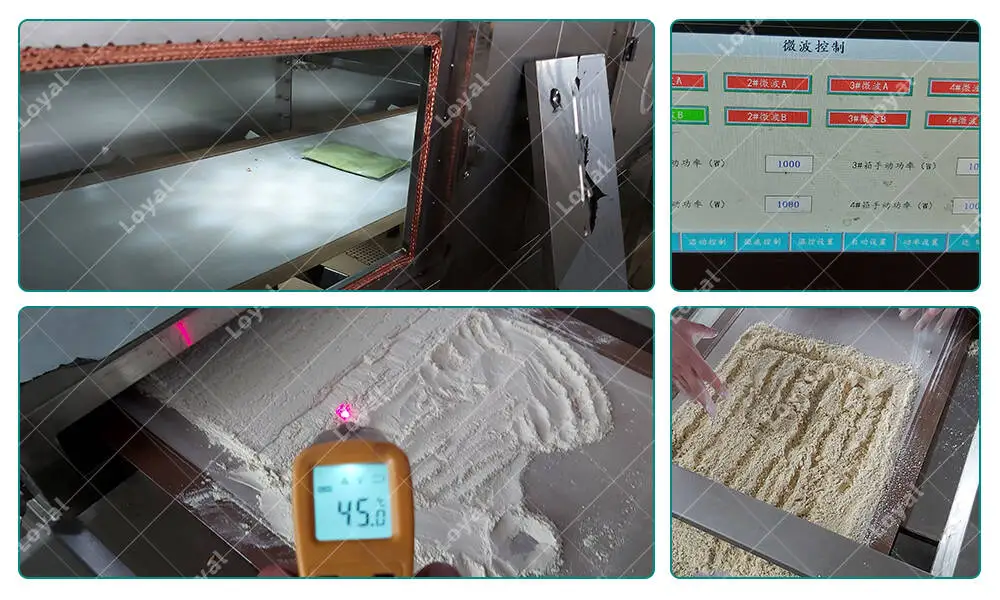

The microwave drying equipment uses microwave to heat the material in a non-contact manner, which overcomes the shortcomings of the traditional process, and the effect is more significant. The relatively hot characteristics of the microwave make the surface and the inside of the material uniformly heated at the same time, the heating speed is fast, and the work efficiency is high. While drying and dehydrating, microwave can also achieve the purpose of sterilizing food.

Microwave heating is the overall heating, that is, heating, the internal and external heating of the material, not the heat of the traditional heating method is conducted from the surface layer of the material.Fast, efficient, safe and environmentally friendly.

Technical Parameters And Price Of Industrial Tunnel Microwave Food Power Drying Sterilization Machine

Technical Parameters And Price Of Industrial Tunnel Microwave Food Power Drying Sterilization Machine | |||

| Type: | Drying Oven | Application: | Low-Temperature Roasting Of Whole Grains |

| Condition: | New | Place Of Origin: | Shandong, China |

| Brand Name: | Loyal | Voltage: | 380v/440v Customized |

| Power: | 20-200kw | Dimension(L*W*H): | 8640 *1200* 2200mm |

| Key Selling Points: | High Productivity | Warranty: | 1 Year |

How To Choose Industrial Tunnel Microwave Food Power Drying Sterilization Machine Of Different Models ?

The model about Industrial Tunnel Microwave Food Power Drying Sterilization Machine | |||||

| No | Model | Power | Dehydration Capacity | Size(L*W*H) | Sterilization Capacity |

| 1 | Ly-12KWSP | 12KW | 12kg/h | 7*0.84*1.75m | 120-150kg/h |

| 2 | Ly-20KWSP | 20KW | 20kg/h | 9.4*0.84*1.75m | 192-240kg/h |

| 3 | Ly-30KWSP | 30KW | 30kg/h | 11.7*0.84*1.75m | 300-375kg/h |

| 4 | Ly-40KWSP | 40KW | 40kg/h | 10.52*1.06*1.75m | 396-495kg/h |

| 5 | Ly-50KWSP | 50KW | 50kg/h | 11.7*1.06*1.75m | 504-630kg/h |

| 6 | Ly-60KWSP | 60KW | 60kg/h | 12.86*1.06*1.75m | 600-750kg/h |

| 7 | Ly-70KWSP | 70KW | 70kg/h | 14.03*1.06*1.75m | 696-870kg/h |

| 8 | Ly-80Kwsp | 80Kw | 80kg/h | 14.86*1.2*1.75m | 804-1000kg/h |

| 9 | Ly-100Kwsp | 100Kw | 100kg/h | 15.2*1.2*1.75m | 1000-1250kg/h |

| 10 | Ly-150Kwsp | 150Kw | 150kg/h | 21.05*1.2*1.75m | 1500-1875kg/h |

What is the working principle of Industrial Tunnel Microwave Food Power Drying Sterilization Machine?

Microwave is a sort of electromagnetic wave which frequency is 300ghz. The water molecule in medium material is polar molecule, under the effect of the repaid change of electromagnetic field, it is polarity orientation will alter with the changes of external electric field with high-speed, causing the movements and friction of molecule, so that the microwave field energy can be converted to heat energy in medium to rise the temperature of materials, accomplishing heating, puffing and a series of physical processes and so microwave is achieved.

Features of Industrial Tunnel Microwave Food Power Drying Sterilization Machine:

Features of Industrial Tunnel Microwave Food Power Drying Sterilization Machine | |

| Microwave output frequency | 2450±50MHz |

| Microwave input apparent power | <70KVA |

| Microwave output power | >50KW |

| Microwave power adjustment range | 10-200KW(adjustable) |

| Temperature | 0~200C(adjustable) |

| Transmisison speed | 0~10m/min(adjustable) |

| Microwave leakage limit | (mW/cm2):<1 |

What’s The Advantages Of Industrial Tunnel Microwave Food Power Drying Sterilization Machine?

The Advantages Of Industrial Tunnel Microwave Food Power Drying Sterilization Machine | ||

| 1 | Drying: | The heating rate is fast, the material is heated for a short time, and it is not easy to cause some unnecessary chemical reaction of the material. |

| 2 | Sterilization: | The microwave machine has sterilization function, the fungus, mycetes and others all can be killed. |

| 3 | Keeping fresh: | The color, taste and nutrition of food can be protected well by using the microwave machine. |

| 4 | Safe: | The machine is specially designed,the microwave will not be leaking. And the machine will not generate extra and pollution. |

| 5 | Easy to operate: | By using plc, makes the operation process simple, stable, safe and friendly. |

The Application Of Industrial Tunnel Microwave Food Power Drying Sterilization Machine

1. Chemical material,medicine tablet or pill,such as watered pills,water-honey bolus,honeyed bolus,condensed pill and tibetan pill,etc.

2.all kinds of teas,herbs, flowers, green leaves,etc.

3.various dried meat, like beef, pork, chicken,duck, fish etc.

4. Powder for various material,such as spices, other food additives.

5. Agricultural products,such as china date,nuts,grains,peanut,etc

6.snack food, fruit seeds, grains, peanuts, chips,etc.

Grains, peanuts, chips,etc.

Which Market Did The Loyal Industrial Tunnel Microwave Food Power Drying Sterilization Machine?

Customer Case Of Powder Drying and Sterilizing Machine At 2021 | |

1 | 100KG/H Thai Millet powder Microwave Drying Sterilizing Curing Machine for Thailand customer |

2 | 100KG/H small industrial microwave oven for sale in Uzbekistan |

3 | 100KG/H microwave dryer microwave drying machine for sale in Nigeria Plant |

4 | 20KW Buckwheat Microwave Drying Sterilizing Curing Machine for sale in Nigeria Factory |

5 | 200KW Grain Microwave Drying Sterilizing Curing Machine for send to India Factory |

6 | 1T/day food sterilizer equipment for chill powder to sale in Canada Agent |

7. | 100kw Red Beans powder Microwave Drying Sterilizing Curing Machine send to Egypt Plant |

Customer Case Of Powder Drying and Sterilizing Machine At 2021 | |

1 | microwave drying machine 100KG/H in Algerian |

2 | 50KG/H industrial automatic industrial belt dryer for sale in Senegal Plant |

3 | 100KG/H industrial drying equipment in pharmaceutical industry sold in Russia Agent |

4 | 5T/day Black Sesame Microwave Drying Sterilizing Curing Machine food sterilizer machine sale in Egypt |

5 | 150kw Pumpkin Seeds powder Microwave Drying Sterilizing Curing Machine send to Iran Agent |

The so-called starchy foods mainly refer to carbohydrate-rich foods and root vegetables. Foods rich in carbohydrates include rice powder, wheat powder, corn powder, etc., and root vegetables include potato powder, potato powder, yam powder, etc. In addition, starchy fruits such as various beans and bananas are also included in starchy foods.

Customer Have Factory Case Of Industrial Powder Drying and Sterilizing Machine At 2021 | |

1 | 200KG/H industrial microwave Cereal flour oven for sale in Bolivia Factory |

2 | Mozambique 150KG/H industrial drying equipment |

3 | 300KG/H industrial continuous belt dryer for sale in Pakistan Factory |

4 | Mozambique 250KG/H industrial herbs leaces tea drying equipment |

5 | 150kw Oatmeal Microwave Drying Sterilizing Curing Machine sterilization in food processing sold to Russia Plant |

6 | 200kw Soybean powder Microwave Drying Sterilizing Curing Machine for sale in Canada |