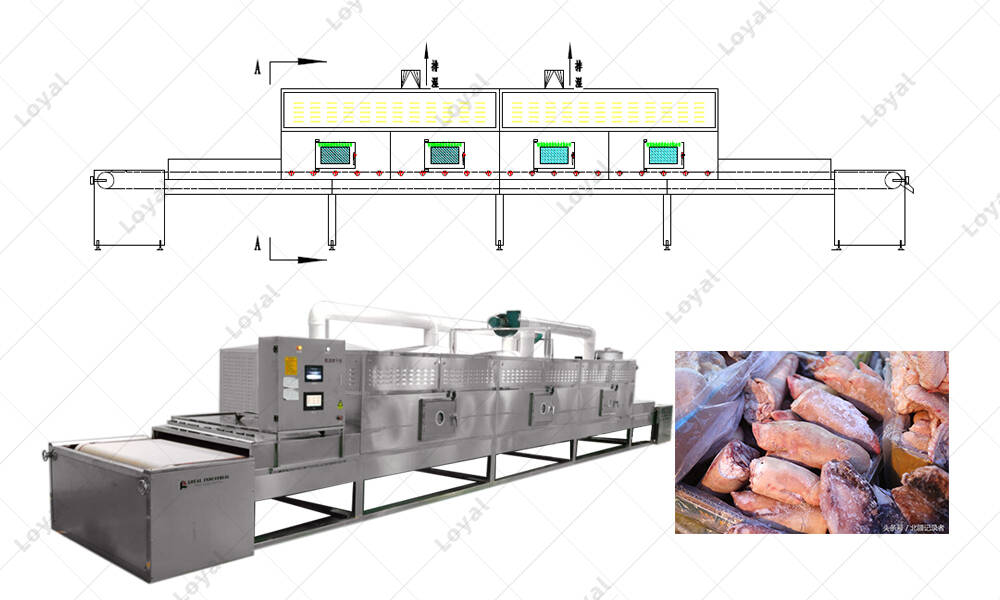

Industrial Microwave Chicken Shrimp Defrosting Equipment

The multifunctional Continuous Microwave Thaw Machine has reasonable price. When air thawing product, boxes are typically thawed on pallets with spacers between the layers. One downside of air thawing is that the process can take multiple days, especially when considering air temperature and velocity. Some other considerable factors include floor space, drip loss and inventory size. Each of these determinants can ultimately increase overall cost. Finally, the process of air thawing has the potential to downgrade overall plant hygiene. In contrast to long-drawn-out process of air thawing, water thawing is a faster overall solution. Water thawing is the technique of choice for many seafood products. It consumes less space than air thawing, yet it is still an unappealing process. Much of the opposition to water thawing frozen product comes from from regulatory concerns. The regulations concerning water usage and waste water quality are valid, and we’ve certainly seen these concerns become increasingly important to food processors and end consumers alike.

Industrial Microwave Chicken Shrimp Defrosting Equipment Specifications :

| Price | Check with Industrial Defrosting Equipment Team Saler |

| Brand Name | Loyal Microwave Industrial Defrosting Equipment |

| Model Number | Industrial Microwave Defrosting Equipment |

| Place of Origin | China |

| Min.Order Quantity | 1set |

| Payment Terms | L/C,T/T, |

| Supply Ability | 25Days of Microwave Defrosting Machine |

| Sale Team | Microwave Industrial Defrosting Equipment Technical Team |

| Honor | A Number Of National Fryer Equipment Patents |

| Technology | 8 Years Of Microwave Technology |

Industrial Microwave Chicken Shrimp Defrosting Equipment Detail Introduction :

The industrial microwave chicken shrimp defrosting equipment method is an internal heating method and is a kind of electric defrosting.

Its principle is that electromagnetic waves act on polar groups of high and low molecules in frozen chicken shrimp, especially on water molecules play a special role. It makes the polar molecules in the high-frequency change of electromagnetic field constantly change the direction of arrangement, change between the molecules to rotate, vibration, collision, friction, generate heat.

The higher the frequency of electromagnetic wave, the greater the collision and friction effect, the more heat generation, the faster the chicken shrimp thawing speed.

Technical Parameters And Price Of Industrial Microwave Chicken Shrimp Defrosting (Machine Industrial Defrosting Equipment):

Industrial Microwave Chicken Shrimp Defrosting Machine | |

| Product | 25 kg blocks of frozen-at-sea, H&G haddock* |

| System | MIP 12 Tempering Tunnel |

| Original Starting Temperature | 7°F (-14°C) |

| Targeted Final Temperature | 26°F (-3°C) |

| Throughput Speed | 140 inches per minute |

| Average Variance | +/- 3°F |

Tempering And Defrosting

Microwave tempering and defrosting are critical to the food processing industry. Since the 1970s, microwave energy has been applied to deep frozen food products, such as beef, poultry, and fish. The process of tempering with industrial microwave systems replaces the need for entire rooms dedicated to the process. In addition to the evident time and space savings, tempering proves beneficial as higher protein yields and flavor compounds remain in the product.

Our food production clients who temper with iindustrial microwave chicken shrimp defrosting equipment see lesser amounts of mess and higher levels of energy efficiency.

Tempering Vs. Thawing

Tempering Vs. Thawing | |

| 1. | The process of microwave tempering is a highly successful alternative to thawing frozen product. Before we completely set aside and discount the practice of thawing, it is important to understand the reasons why food processors thaw their product, and the two associated methods of thawing. |

| 2. | Frozen foods, of course, are heavily reliant upon frozen ingredients. For meats, such as steak or ground hamburger, the process of freezing then thawing permits further processing – from slicing and dicing, to grinding and forming. Food processors portion servings by thawing frozen meats to a desired temperature at which they can then cut or split the product into fractioned amounts. The process of “thawing” involves melting the crystals into the product. There are two methods for tempering frozen product; air and water. |

| 3. | When air thawing product, boxes are typically thawed on pallets with spacers between the layers. One downside of air thawing is that the process can take multiple days, especially when considering air temperature and velocity. Some other considerable factors include floor space, drip loss and inventory size. Each of these determinants can ultimately increase overall cost. Finally, the process of air thawing has the potential to downgrade overall plant hygiene. |

| 4. | In contrast to long-drawn-out process of air thawing, water thawing is a faster overall solution. Water thawing is the technique of choice for many seafood products. It consumes less space than air thawing, yet it is still an unappealing process. Much of the opposition to water thawing frozen product comes from from regulatory concerns. The regulations concerning water usage and waste water quality are valid, and we’ve certainly seen these concerns become increasingly important to food processors and end consumers alike. |

What Are The Different Food Thawing/ Chicken Shrimp Defrosting Technologies?

Before processing or cooking, most frozen foods need to be thawed in order to obtain a suitable result. Here are the most common defrosting methods and their advantages and drawbacks …

Several Forms Of Traditional Chicken Shrimp Thawing | ||

| No. | Forms Of Defrost Machine | Drawbacks |

| 1. | Cold Room Thawing | Thawing In a Cold Room Is One Of The Most Common Methods. Frozen Chicken Shrimp Is Stored In a Room At a Temperature Around 5 ° C With Air Circulation, Until It Slowly Reaches Room Temperature. However, This Simple Solution Has Several Drawbacks: The Defrosting Time Can Last Up To 48 Hours, The Result Is Not Always Homogeneous, But Above All Significant Food Drip losses Occur. |

| 2. | Cold Water Thawing | This Method Is Faster Than Defrosting In a Cold Room, But Requires More Care. Food Should Be In An Airtight Package Or Plastic Bag. If The Bag Leaks, Bacteria In The Water Can Contaminate The Chicken Shrimp. In Addition, The Meat Tissue Can Absorb Water Resulting In a Watery Product. Relatively Efficient For Defrosting Whole Chicken Shrimp, This Method Is Not Well Suited For Other Foods. |

| 3. | Tumbling Thawing | Tumbling Thawing Involves a Rotating Drum Whose Walls Are Slightly Heated. On Some Cases, Cold Steam Under Vacuum Is Added To Improve The Process. This Solution Is Faster Than Cold Room Defrosting As It Takes Hours Instead Of Days. But This Process Is Not Continuous, Which Is Not Really Suitable For Processing Of Large Amount Of Food And Not Adapted At All For Delicate Products Like Fruits And Vegetables. |

| 4. | Open Air Thawing | Although Still Used In Some Places, Open Air Thawing Is Prohibited In Many Countries. This Is Because This Method Is Faster Than Thawing In a Cold Room, But The Surface Of The Food Can Reach Temperatures Where Bacteria Grow Rapidly, Making The Food Unsafe For Consumption, Even After Cooking. In Addition, Significant Driploss Occur With This Solution. It Is Therefore a Method To Be Totally Avoided. |

High-Tech Thawing Microwave | ||

| No. | Forms Of Defrost Machine | Advantages |

| 1. | Microwave thawing | The microwave and radio frequency have the property to thaw the entire mass of a product quickly and homogeneously. Unlike other solutions, where heat is transferred by conduction from the surface of the food to its core, the waves goes through the entire food block. It is called « volumetric heating ». The speed of the process prevents drip-loss or bacterial growth. The defrosting by microwave or radio frequency takes from 3 to 20 minutes instead of hours or days with traditional methods, even for large food blocks. This technology is adapted even for sensitive products like fruits and vegetables. |

Post-Tempering Processes Of Industrial Microwave Defrosting Machine Industrial Defrosting Equipment:

Tempering has a positive impact on processes such as slicing, dicing, grinding, forming and thawing. It is an exacting process, in which temperature increases of up to 15°C can be achieved in 3 minutes or less. In each post-tempering process, there can be effects of under- or over-tempering. This is why it is critical to invest in precise microwave systems.

Post-Tempering Chicken Shrimp Processes | ||

| Process | Effect of Under-Tempering | Effect of Over-Tempering |

| SLICING | Equipment failure Curled and shattered slices Smeared slices | Incomplete slices (strings) Excessive fines Ragged edges |

| DICING | Equipment failure Excessive fines Broken dices | Incomplete dices (strings) Excessive fines |

| PRESSING | Equipment failure Shattered meat Ragged surface Reduced productivity | Blood loss Ragged surface |

| GRINDING | Equipment failure Shattered meat Excessive lines | Blood loss |

| CONTROLLING TEMPERATURE AT PATTY FORMER | Equipment failure Lack of weight control Incomplete forming Lack of patty bind | Lack of weight control Ragged edges Sticky patties Wasted refrigeration |

| CONTROLLING TEMPERATURE OF SAUSAGE BLEND | Unsatisfactory protein extraction Unsatisfactory stuffing Smeared appearance | Protein loss Wasted refrigeration |

What Advantage Of Industrial Microwave Defrosting Machine Industrial Chicken Shrimp Defrosting Equipment?

Although thawing may be viable for certain applications, we overtly recommend the practice of microwave tempering as an effective substitute. A significant benefit of tempering is its ability to improve further processing downstream. After applying microwave heat, those who slice, form, dice, or grind food (particularly meat), will find a more uniformly conditioned product.

Generally, we’ve seen the benefits of microwave tempering range from improved response time, to improved heat balance control.

Taking deep frozen product and increasing temperature for further processing is no easy task. In fact, it is quite demanding. Before industrial microwave systems, facilities dedicated entire rooms strictly for tempering. This commonplace method caused a number of issues – from wasted space, to product spoilage, to labor-intensive cleanup and management. Given that each of these problems indefinitely drive up cost, many food processors moved toward tempering systems as a means of economic efficiency.

Which Market Did The Loyal Industrial Industrial Microwave Defrosting Machine Industrial Chicken Shrimp Defrosting Equipment?

Customer Have Formula Request Of industrial Microwave Defrosting Machine Industrial Defrosting Equipment manufacturers | |

1 | China 300t/year continuous industrial Meat Microwave & Rf Tempering And Thawing Technology |

2 | 200kg/h Plc Industrial Tempering And Defrosting for Sale In Puerto Rico Agent |

3 | 300kg/h lndustrial Meat Defrosting Machine for Sale In Bolivia |

4 | 800kg/h Industrial Quick Defrost Machine for Sale In argentina |

5 | 100kg/h Fully Industrial Defrosting Equipment manufacturers for Sale In Benin |

6 | 500kg/h Plc control fully Automatic Industrial Microwave Defrosting Machine Industrial Defrosting Equipment for Sale In british Indian Ocean Territory |

7 | 200kg/h PLC Control fully Tempering And Defrosting industrial Meat Defrosting Machine for Sale In Chile |

Cooperated Customer For Laboratory Machine Of plc Control industrial Microwave Defrosting Machine Industrial Defrosting Equipment | |

1 | Senegal 200kg/h Industrial Microwave Tempering And Defrosting Equipment |

2 | 100-200kg/h Industrial Microwave Chicken Shrimp Defrosting Equipment For Sale In Côte D'ivoire |

3 | 300-400kg/h Industrial Microwave Chicken Shrimp Defrosting Equipment For Sale In sold In Russia Agent |

4 | 500kg/h Industrial Continuous Microwave Chicken Shrimp Defrosting Equipment For Sale In sold In Denmark |

5 | 600kg/h PLC Industrial Microwave Chicken Shrimp Defrosting Equipment for Sale In Dominica |

6 | 100-200kg/h Tempering And Defrosting Equipment Chicken Shrimp Defrosting Equipment For Sale In Egypt |

7 | 300-400kg/h Tempering And Defrosting Shrimp Defrosting Equipmentfor Sale In sold In ethiopia |

Cooperated Customer Request Engineer Installation At 2021 | |

1 | 300kg/h PLC Control Continuous Dough Snack fryer for Sale In Uzbekistan |

2 | 100kg/h Industrial fully Automatic Industrial Defrost Machine for Sale In Senegal |

3 | Mozambique 400kgt/h Fully Automatic Industrial Defrost Chicken Shrimp Machine |

4 | 200kg/h PLC Control Industrial Tempering And Defrosting Equipment Defrost Chicken Shrimp Machine |

5 | Uzbekistan 100kg/h PLC Control industrial Defrost Machine |

6 | 500kg/h Fully Automatic Industrial Defrost Machine for Sale In germany |

7 | 200kg/h Fully Automatic Industrial Tempering And Defrosting Equipment Defrost Chicken Shrimp Machine for Sale In guinea |

Cooperated Customer With fully Automatic industrial Defrost Machine technology At 2021 | |

1 | Nigeria 500kg/h Tempering And Defrosting Equipment Industrial Quick Defrost Machine |

2 | Austria Sells fully Automatic industrial Quick Defrost Machine 1000kg/h |

3 | Industrial Quick Defrost Machine sale In Pakistan 100kg/h |

4 | 100kg/h Fully Automatic industrial Quick Defrost Machine for Sale In india Agent |

5 | 200kg/h Industrial Tempering And Defrosting Equipment Quick Defrost Machine for Sale In israel |

6 | 200kg/hPLC Control Industrial Quick Defrost Machine for sale in jamaica |

7 | 200kg/h PLC Control Industrial Tempering And Defrosting Equipment Quick Defrost Machine for Sale In Morocco |