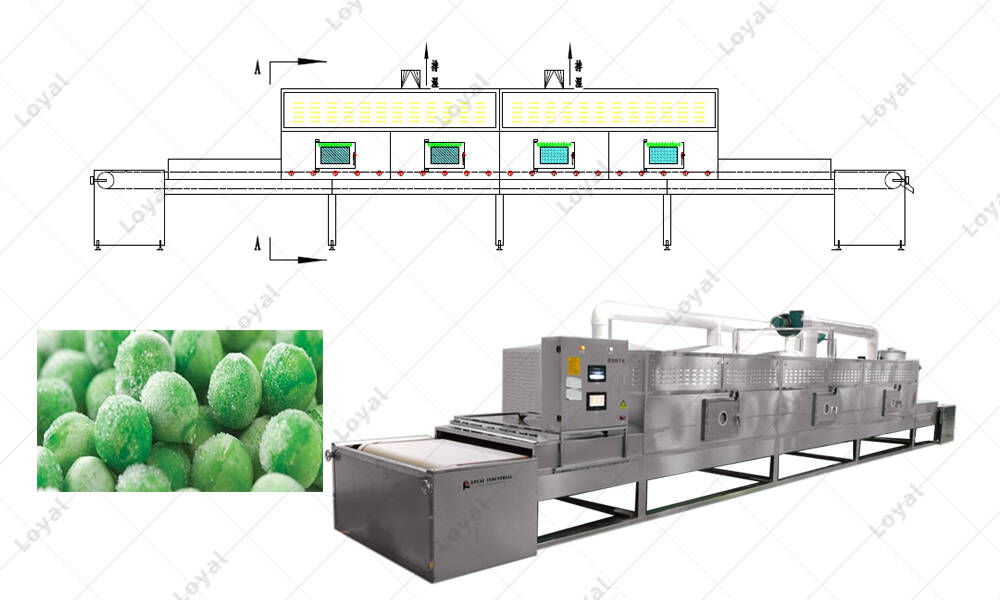

PLC Control Industrial Microwave Frozen Fruit Thawing Machine

As a high-tech-oriented modern technology-based industrial microwave quick tempering and defrosting equipment for frozen fruit enterprise integrating r&d and manufacturing, we produce quick defrost machine for frozen fruit, microwave heating equipment, and microwave sterilization equipment. We have a strong technical development team of industrial microwave thawing machine, and have more than ten years of technical reserves for industrial microwave thawing machine production technology research. We are a leading microwave equipment manufacturer in the domestic industry. Microwave Frozen Fruit thawing equipment can be production according to customer process characteristics and capacity. Defrosting equipment for fruit in the structure performance thaw effect can be fully comparable with import equipment in the structure, performance and thaw effect, but the price is much lower then imported equipment. Microwave Frozen Fruit thawing equipment can be production according to customer process characteristics and capacity.

PLC Control Industrial Microwave Frozen Fruit Thawing Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | LOYAL Microwave Fruit Thawing Machine |

| Model Number | Microwave Frozen Fruit Thawing Machine production line |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Frozen Fruit Thawing Machine |

| Payment Terms | L/C,D/A, |

| Supply Ability | 25Days of Microwave Fruit Thawing Machine |

| Delivery Detail | 20days--35days |

| Packaging Details | Export-compliant microwave equipment packaging |

| Sale Team | Microwave Drying Sterilizing Machine Technical Team |

| Honor | A number of national microwave equipment patents |

| Technology | 8 years of microwave technology |

| Process | Ten years of microwave equipment manufacturing process |

PLC Control Industrial Microwave Frozen Fruit Thawing Machine Detail Introduction :

How To Defrost Frozen Fruit?

915 MHz Time saving automatic frozen fruit vegetables jam fruits heating defrosting machine line thawing equipment can heat the frozen products(-18 ºC) within a few minutes. When the frozen product come out from the tunnel equipment, it will get defrosted, but without any leakage of the original liquid and no lose of nutrients.

Features Of Full Automatic Frozen Fruit Microwave Thawing Machine:

Microwave thawing equipment used for frozen fruit, meat and seafood(fish,shrimp etc)thaw, stable equipment performance, reliable quality with CE certificate, bring huge economic efficiency for users, get user's high praise deeply, is the ideal high-tech frozen fruit thaw equipment. Defrosting equipment for fruit in the structure performance thaw effect can be fully comparable with import equipment in the structure, performance and thaw effect, but the price is much lower then imported equipment. Microwave Frozen Fruit thawing equipment can be production according to customer process characteristics and capacity.

What’s The Parameters And Price Of The Industrial Microwave Thawing Equipment For Frozen Fruit?

Technical Parameter Of Microwave Frozen Fruit Tempering And Defrosting Equipment : | |

Product Name | Microwave Thawing Machine |

Device Type | Transmission Belt |

Microwave Frequency | 2450±50Mhz |

Power | 00Kw |

Size | 8.4m*1.1m*1.7m |

Transmission Speed | 0-5m/Minute |

Input Voltage | Three-Phase ac 380V |

Weight | 1300kgs |

Cabinet Color | Silverh White |

The Whole Material | Industrial Grade Stainless Steel |

Microwave Leakage Limit | ≤1mw/Cm² |

Working Time | 24hours |

Compared With Traditional Water Thawing, What’s The Advantages Of PLC Control Industrial Microwave Frozen Fruit Thawing Machine?

Compared With Traditional Water Thawing, The Advantages As Below: | |

| 2 | Fast Speed And Short Time; |

| 2 | High Product Quality; |

| 3 | Heating Evenly; |

| 4 | The Thermal Heating Process With Automatic Balance Performance; |

| 5 | Responsive And Easy To Control. |

| 6 | No Waste Of Water |

| 7 | No Waste Of Water |

| 8 | No Waste Of Water |

| 9 | No Waste Of Water |

| 10 | No Flood Liquid |

| 11 | 1-2 Labors Control, Save Labor Cost |

| 12 | Low Power Consumption |

| 13 | Easy Operation |

| 14 | Compact Size |

What’s The Applications Of Our 2450Mhz Microwave Quick Defrost Machine For Frozen Fruit?

| Other Applications Of Our 2450Mhz Microwave Equipment | |

| 1 | Chemical Material, Medicine Tablet Or Pill, Such As Watered Pills, Water-Honey Bolus, Honeyed Bolus, Condensed Pill And Tibetan Pill, Etc. |

| 2 | All Kinds Of Teas, Herbs, Flowers, Green Leaves,Etc. |

| 3 | Various Dried Meat, Like Beef, Pork, Chicken, Duck, Fish Etc. |

| 4 | Powder For Various Material, Such As Spices, Other Food Additives. |

| 5 | Agricultural Products, Such As China Date, Nuts, Grains, Peanut, Etc. |

| 6 | Snack Food, Fruit Seeds, Grains, Peanuts, Chips, Etc. |

| 7 | Wet Spinning Linen Yarn Etc. |

How About The Loyal Cooperated Customers Of Industrial Microwave Quick Defrost Machine For Frozen Fruit?

| Cooperated Customer Request Engineer Installation Microwave Thawing Equipment For Frozen Fruit At 2021 | |

| 1 | Spain 300T/Year Microwave Tempering And Defrosting Machine For Frozen Grapes |

| 2 | 1T/H Microwave Thawing Equipment For Frozen Strawberries In Puerto Rico |

| 3 | 1T/H Industrial Microwave Frozen Blueberries Thawer For Sale In Bolivia |

| 4 | Senegal 1T/H Quick Tempering And Defrosting Equipment For Frozen Cherry Manufacturing Equipment |

| 5 | 1T/H Microwave Thawing Equipment For Frozen Grapes For Sale In Côte d'Ivoire |

| 6 | 1T/H Industrial Microwave Frozen Pineapple Thawing Machine Sold In Russia |

| Customers Who Buy Microwave Tempering And Defrosting Equipment For Fruit For The Second Time | |

| 7 | 100kg/H Industrial Frozen Cherry Defrosting Machine Equipment For Sale In Uzbekistan |

| 8 | 100kg/h Industrial Automatic Microwave Tempering And Defrosting Equipment For Freezing Kiwi For Sale In Senegal |

| 9 | Mozambique 1T/H Automatic Microwave Quick Defrost Machine For Frozen Fruit Machine |

| 10 | Bangladesh 2T/h Industrial Automatic Continuous Industrial Microwave Quick Defrost Machine For Frozen Fruit Raspberries |

| 11 | 1T/H Microwave Frozen Cherry Defrosting Machine Equipment |

| 12 | Uzbekistan 1T/H Microwave Frozen Pineapple Thawing Machine |

| 13 | USA 1T/H Tempering And Defrosting Equipment For Frozen Raspberries |

| 14 | 50kh/h Industrial Microwave Frozen Cherry Defrosting Machine Equipment For Sale In Nigeria |

| Customers Who Purchase Microwave Thawing Machine For Frozen Fruit Through The Introduction Of Old Customers At 2021 | |

| 15 | Algerian Microwave Frozen Fruit Thawing Machine 300kg/h Production Line |

| 16 | Sudan 200kg/h Microwave Thawing Machine For Frozen Raspberries |

| 17 | Moldova Small 200kg/h Microwave Tempering And Defrosting Equipment For Fruit Food Thawing |

| 18 | 200kg/h Continuous Industrial Microwave Thawing Machine For Frozen Grapes Sold In Ukraine |

| 19 | USA 150Kg/H Microwave Frozen Pineapple Thawing Machine |

| 20 | Austria Sells Industrial Microwave Frozen Fruit Thawing Machine 100kg/h |

| Cooperated Agent Of Microwave Thawing Machine For Frozen Fruit At 2021 | |

| 21 | Nigeria 150Kg/H Microwave Frozen Fruit Thawing Machine Machinery |

| 22 | Industrial Vegetable Microwave Frozen Pineapple Thawing Machine For Sale In Pakistan 100kg/h |

| 23 | Austria Sells Industrial Microwave Food Thawing Machine Machine 100kg/h |

| 24 | 500Kg/H Microwave Thawing Machine For Frozen Kiwi For Sale In Botswana |

| 25 | Nigeria 250kg/h PLC Control Microwave Frozen Pineapple Thawing Machine |

| 26 | Algerian Microwave Thawing Machine For Freezing Grapes 300kg/h |