Efficiently Save Time Industrial Microwave Chicken Meat Thawing Machine For Factory Use

Industrial microwave thawing has the characteristics of overall temperature recovery of frozen materials, small temperature gradient of recovery temperature, that is, good temperature uniformity and short time required, and easy control of temperature rise rate. Industrial microwave thawing characteristics make the frozen material thaw to an ideal state. Shandong Loyal Industrial relies on complete product specifications, excellent product quality and professional services. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company's products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world. If you are interested in the meat defrosting machine, please contact LOYAL immediately, we will provide you with high-quality formulations of meat defrosting, professional technical process guidance, and a full range of professional market analysis.

Efficiently Save Time Industrial Microwave Chicken Meat Thawing Machine For Factory Use Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | LOYAL Microwave Meat Thawing Machine |

| Model Number | Industrial Microwave Chicken Meat Thawing Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Chicken Meat Thawing Machine |

| Payment Terms | L/C,D/A,D/P,T/T, |

| Supply Ability | 25Days Microwave Meat Thawing Machine |

| Delivery Detail | 20days--35days |

| Packaging Details | Export-compliant microwave equipment packaging |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sale Team | Industrial Microwave Date Drying Sterilizing Machine Team |

| Honor | A number of national microwave equipment patents |

| Technology | 8 Years Of Microwave Technology |

Efficiently Save Time Industrial Microwave Chicken Meat Thawing Machine For Factory Use Detail Introduction :

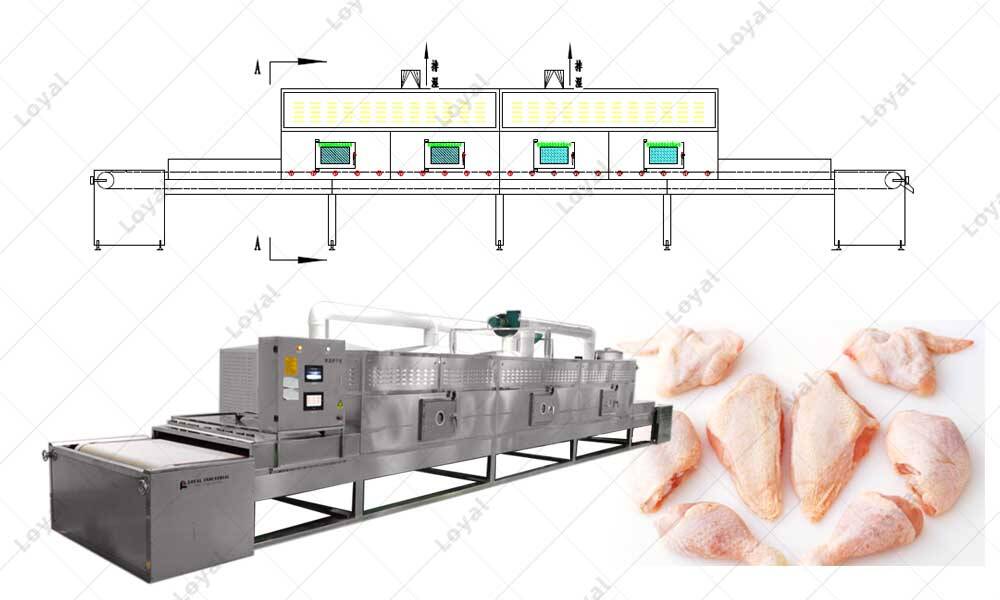

Introduction Of Industrial Microwave Chicken Meat Thawing Machine

To thaw chicken, refers to raising the temperature of frozen chicken from a deep freeze to below a value of zero degrees. It is generally about -5°c, at which time the food can be sliced and divided. For thawing, the temperature must be raised to room temperature or higher than 0°c to make the food out of the frozen state. The use of microwave technology has many distinct advantages over conventional methods. Microwave thawing processing time is greatly shortened, easy to control, color and freshness can be maintained, less loss of nutrients and water, low bacterial content, less energy consumption, small footprint, improved labor conditions and environment. Microwave thawing process: Food is quick-frozen at -20°c ----- microwave thawing and heating at -4°c will break the crystals.

Technical Parameters Of Industrial Microwave Chicken Meat Thawing Machine

| Industrial microwave thawing for chicken breast | |

| 1. Model | LY |

| 2. Microwave Frequency | 915±25mhz |

| 3. Microwave Power | 75kw (continuously adjustable) |

| 4. Transmission Speed | 0.1~3m/min frequency conversion speed regulation |

| 5. Microwave Leakage | ≤5mw/cm2(gb5959.6-87) |

| 6. Thawing Amount | 0.5~1.5t/h |

| 7. Appearance Size Of Equipment | L×w×h8000×5000×2300(mm) |

| 8. The Material Can Pass Through The Maximum | 400×200(mm) |

| 9. Working Environment | Temperature 5 ~ 40 ℃, relative humidity below 90%, no corrosion, no open flame, indoors. |

| 10. Control Method | Touch screen, plc control |

| 11. Standard | Comply with gb 10436-1989 workplace microwave radiation hygiene standard |

| 12. Safety | Comply with gb/5226.1-2002 mechanical safety mechanical electrical equipment |

| 13. Effects | The frozen material can be heated and returned to temperature as a whole, which reduces the temperature unevenness between the thawing layers of the frozen product, and there is no recrystallization phenomenon of the frozen product when it is thawed by the conventional method; |

| 14. Time | The thawing process takes a short time, and microorganisms such as bacteria are not easy to reproduce and grow; |

| 15. Microwave Heating Has No Thermal Inertia | The temperature rise rate of the frozen material is controlled by the microwave output power, or the microwave energy supply rate, which is synchronized with each other. |

| 16. Temperature | The final temperature of microwave thawing is generally suitable to be -2─-4 c. At this time, the frozen product can be cut with a knife without dripping water. |

How To Quickly Defrost Chicken Breast?

The high power density 915mhz microwave penetrates meat products to ensure uniform temperature inside and outside after thawing. It only takes 10 minutes to go from -18°c to -2°c. It is the best way to thaw meat products at present, and the thawed meat products include: Beef, chicken, fish, shrimp slips, pork and other products.

Traditional Chicken Thawing VS Chicken Industrial Microwave Thawing

| Industrial Meat Thawer Food Thawer Microwave Thawing | |

| Traditional Chicken Defrost | Chicken industrial Microwave Thawing |

| Traditionally, water thawing method and natural thawing method are generally used for thawing. Energy is mainly transferred through heat conduction. Since the heat conduction method is first heated by the surface of the material, the surface of the frozen product is easily heated to generate water, which reduces the thermal conductivity and causes the thawing speed to slow down. | The chicken microwave thawing machine heats the frozen material as a whole, and the temperature rises from the deep-freezing temperature (below -19~-22 c) to a temperature close to the freezing point (about 0~-4 c). Microwave thawing has the characteristics of overall temperature recovery of frozen materials, small temperature gradient of recovery temperature, that is, good temperature uniformity and short time required, and easy control of temperature rise rate. |

| Industrial Meat Thawer Food Thawer Microwave Thawing Meat Defrosting Machine | |||||||||

| Method ¶meter | Temperature And Humidity Control | Color | Time | Water Loss | Order Of Magnitude Of Harmful Flora | Power Consumption | Water Consumption | Sewage Treatment | Maturity |

| Air nature | No | Dim | 24 Hours | 5% | 1000 | 0 | 0 | High cost | High |

| Thaw | No | Gray | 8-10 hours | 3~5% | 10000 | 0 | 18~25 tons | High cost | High |

| High frequency | Temperature control | Fresh Meat | 0.5 Hours | ≤1% | 1000 | 45~55kw-h | 0 | None | Low |

| Low Temperature And High Humidity | Temperature And Humidity Control | Glossy | 13~20 Hours | 0.5% | 100o | 18kw·h | 0.2 tons | Lower | High |

| Microwave | Temperature Control | Fresh Meat | 0.2 Hours | <0.01% | 100 | 25~35kw-h | 0 | None | High |

Customer Purchase Case Of Automatic Frozen Meat Defrosting Microwave Thawing Machine Equipment For Chicken

Shandong Loyal Industrial relies on complete product specifications, excellent product quality and professional services. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company's products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world. If you are interested in the meat defrosting machine, please contact LOYAL immediately, we will provide you with high-quality formulations of meat defrosting, professional technical process guidance, and a full range of professional market analysis.

Customer Cases For Frozen Shrimp Microwave Thawing Machine Pork Beef Sheep Meat Defrosting Equipment For Factory In 2021 | |

| 1 | 1t/h Cost Of Microwave Drying Equipment Sold In Russia |

| 2 | 1t/h Industrial Microwave Price For Factory For Sale In Puerto Rico |

| 3 | 1t/h Meat Tempering Systems For Sale In Bolivia |

| 4 | Senegal 1t/h Industrial Fully Automatic Industrial Sized Microwave |

| 5 | 1t/h Industrial Sized Microwave For Sale In Côte d'Ivoire |

| 6 | China 300t/Year Industrial Fully Automatic Industrial Sized Microwave |

Customer Case Of Frozen Meat Thawing Machine Tuna Defrosting Equipment At 2021 | |

| 1 | 1t/h Microwave Drying Equipment For Factory In Uzbekistan |

| 2 | 1000kg/h Industrial Microwave Drying Equipment For Sale In Senegal |

| 3 | Mozambique 1t/h Fully Automatic Microwave Industrial Microwave Tempering And Defrosting Equipment |

| 4 | Bangladesh 2t/h Chicken Equipment Defrosting Frozen Pork Fish Prawn Chicken Thawing Machine Microwave Thawing Equipment Meat Defrosting Machine |

Dealed Customer Have Technology Of Microwave Drying Equipment At 2021 | |

| 1 | 1t/h Thai Automatic Microwave Thawing Equipment Machine For Chicken Meat For Factory |

| 2 | Uzbekistan 1t/h Microwave Defrosting For Chicken Equipment Tunnel Type Industrial Microwave Defrosting Machine Thawing Machine For Meat Chicken Beef Unfreeze Equipment |

| 3 | USA 1t/h Microwave Thawing Defrosting Machine Chicken Breast |

| 4 | 800kg/h Chicken Thawing Room For Defrosting Machine Frozen Meat Microwave Thawing Machine Equipment For Sale In Nigeria |