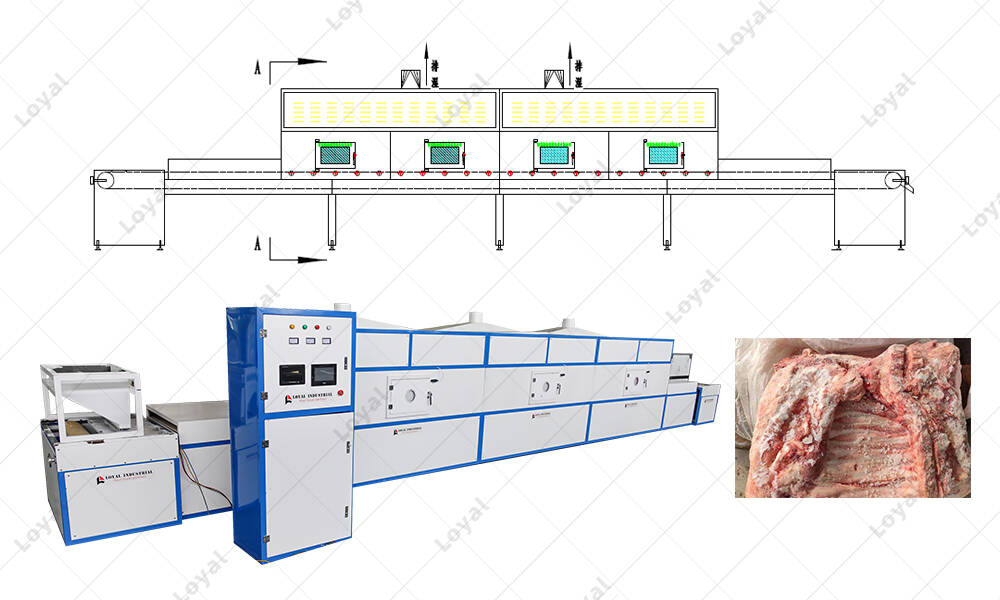

Tunnel Microwave Frozen Meat Mutton Processing Thawing Machine

As a professional tunnel microwave thawing machine suppliers, our frozen meat defrosting thawing machine equipment are widely used for the thawing of frozen seafood, frozen meat, meat products, various fish and fish roe, etc. The industrial automatic microwave thawing equipment can not only realize the freezing and processing of frozen products, but also complete thawing and curing, and also has a bactericidal effect. Compared with the traditional production thawing technology methods, the frozen meat microwave thawing machine use a microwave source with a frequency of 2450MHZ or 915MHZ. When heating, the microwave penetrates the material inside and outside and heats at the same time, without heat conduction, industrial microwave frozen meat thawing machine can be thawed with packaging, fast speed, low energy consumption, environmental protection and hygiene. The processing capacity of the microwave thawing machine is related to the quality of the meat, that is, to the dielectric constant of the meat.

Tunnel Microwave Frozen Meat Mutton Processing Thawing Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Tunnel Microwave Frozen Meat Mutton Processing Thawing Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Delivery Detail | 20days/Microwave equipment assembly completed |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sales Team | Professional microwave technology team |

| Honor | A Number Of National Microwave Equipment Patents |

| Technology | 8 Years Of Microwave Technology |

Tunnel Microwave Frozen Meat Mutton Processing Thawing Machine Detail Introduction :

As a professional tunnel microwave thawing machine suppliers, our frozen meat defrosting thawing machine equipment are widely used for the thawing of frozen seafood, frozen meat, meat products, various fish and fish roe, etc. The industrial automatic microwave thawing equipment can not only realize the freezing and processing of frozen products, but also complete thawing and curing, and also has a bactericidal effect. Compared with the traditional production thawing technology methods, the frozen meat microwave thawing machine use a microwave source with a frequency of 2450MHZ or 915MHZ. When heating, the microwave penetrates the material inside and outside and heats at the same time, without heat conduction, industrial microwave frozen meat thawing machine can be thawed with packaging, fast speed, low energy consumption, environmental protection and hygiene.

The industrial automatic microwave thawing equipment can be used for the thawing of frozen seafood such as meat products, meat mutton, various fish and etc. Microwave thawing technology can maintain the taste of thawed materials through thermal effect and biological effect, and nutrients such as protein and vitamins are not damaged. At the same time, tunnel microwave thawing machine has bactericidal effect and improves product quality. The microwave frequency of the equipment adopts a 915MHz microwave generator, and its penetrating power is far better than that of a 2450MHz microwave source. The processing capacity of the microwave thawing machine is related to the quality of the meat, that is, to the dielectric constant of the meat.

What Is The Best Method For Thawing Frozen Meat?

Mutton meat are a common meat product nowadays. Usually, when families take meat out of the refrigerator, all they have to do is thaw them at indoor temperature or in cold water. In the factory, this method not only takes a long time, but also causes uneven temperature inside and outside, and the meat is dark in color, poor quality and easy to breed bacteria. But the tunnel microwave frozen meat mutton processing thawing machine is a good solution to these problems.

Technical Parameter of Microwave Thawing Equipment

Technical Parameter Of Tunnel Microwave Thawing Machine | |||||

| Model | Power | Output | Specification | Allocation | Control |

| LY-25KW-F(S) | 25KW | 300-400KG/H | 9000X1500X2400MM | Water/air cooling | PLC |

| LY-50KW-F(S) | 50KW | 600-800KG/H | 12000X1500X2400MM | Water/air cooling | PLC |

| LY-100KW-F(S) | 100KW | 1200-1500KG/H | 18000X1500X2400MM | Water/air cooling | PLC |

Notes: 1. Power supply: 380V±10% 50Hz±1% Three-Phase Five-Wire, (must be equipped with a dedicated ground wire) 2. Microwave frequency: 915MHz 3. Input power: 25-125kVA 4. Microwave output power: 20-100kw (adjustable) | |||||

What Is The Principle Of The Frozen Meat Defrosting Thawing Machine Equipment ?

Microwave thawing is under the physical action of electromagnetic waves, using polar molecular vibration to generate elastic collision with surrounding molecules to generate frictional heat, thereby producing the effect of thawing. The main feature of frozen meat microwave thawing machine is that thawing does not thaw (-4℃-0℃). Due to the different dielectric constants of ice and water, the ability to absorb microwaves is also different, so microwave thawing needs to be controlled below zero to prevent the generation of blood water above zero. Tunnel microwave thawing machine is also very beneficial to processing such as cutting, so the food thawed by this method has the advantages of low production cost, high efficiency, no bacterial growth and small footprint.

What Is The Feature Of The Industrial Automatic Microwave Thawing Equipment ?

The Features Of The Frozen Meat Microwave Tempering And Defrosting Machine | ||

No | Features Of Microwave Thawing Machine | Details Description |

| 1 | Rapid Thawing And High Efficiency | Since microwaves can be heated directly into the material without conduction, microwave thawing machine only takes 2 minutes for a piece of meat in 25 kg to rise from -15 to -4 degrees, and the thawing time is changed from "hour" to "minute". |

| 2 | Saving Investment, Environmental Protection, And Pollution-free | Frozen meat defrosting thawing machine equipment saves a large number of shelves and floor space required by natural defrosting, which can be defrosted in the package, reducing the requirements on the sanitary environment. The wastewater resources during the thawing of water can be avoided to prevent the pollution of oily sewage and the loss of lipids. |

| 3 | Ensure The Nutrition Of Materials Without Corruption | Before microwave thawing, it is the process of cold storage, which avoids the mass reproduction of bacteria in the process and the material defrosting and exudation, and reduces the rate of meat loss. |

| 4 | Wide Application | Frozen shrimp meat microwave thawing machine can defrost beef, lamb, frozen meat, seafood, and other products, and sterilize the process to maintain taste and color! |

What Is The Applications Of The Tunnel Microwave Thawing Machine?

Microwave frozen product thawing equipment is mainly used for rapid thawing of meat or non-meat frozen products such as seafood, aquatic food, chicken meat, pork meat, beef, mutton, fruit and other agricultural products.

What Kind Of Tunnel Microwave Thawing Machine Has Been Loyal Sold In 2021

Customer Case Of Frozen Meat Microwave Thawing Machine In 2021 | |

1 | 100kg/h Frozen Sardine Fish Microwave Tempering And Defrosting EquipmentFor Sale Senegal |

2 | Tunnel Type Microwave Continuous Fast Frozen Beef Meat Tempering And Defrosting Equipment For Sale Nigeria |

3 | Tunnel Type Microwave Continuous Fast Frozen Chicken Meat Thawing Machine For Sale Burkina Faso |

4 | 50kw Industrial Microwave Frozen Pork Meat Thawing Machine For Sale Botswana |

| Automatic Microwave Frozen Meat Beef Thawing Machine For Sale To America |

Customer Case Of Microwave Thawing Machine At Discount Prices In 2021 In India Agent | |

1 | 800-1000kg/Hfrozen Seafood Oysters Microwave Thawing Machine For Sale Mozambique |

2 | Industrial Frozen Meat Fruit Vegetables Microwave Tempering And Defrosting Equipment Defrosting Machine For Sale Austria |

3 | Duck Meat Continuous Microwave Thawing Machine For Sale Moldova |

4 | 500kg/h Frozen Beef Microwave Tempering And Defrosting Equipment For Sale In Ukraine Agent |

5 | Automatic Frozen Food Thawing Defrosting Machine For Meat Products Freezing For Sale Singapore |

Transaction Case Customer With Meat Defrosting Machine Technology In 2021 | |

1 | 600kg/H Industrial Microwave Frozen Food Thawing Machine For Sale Puerto Rico |

2 | High Efficiency Thawing Machine For Frozen Sea Meat Food To Bolivia |

3 | 800kg/h Industrial Microwave Frozen Seafood Thawing Machine Cost For Sale Dominica |

4 | New Design Insdustrial Plc Microwave Freezing Meat Defrosting Seafood Thawing Machine For Sale For Sale In Senegal |

5 | Meat Microwave Thawing Frozen Food Defrosting Machine Price In Nigeria |

Repurchase Case Of The Frozen Meat Defrosting Thawing Machine Equipment In 2021 | |

1 | Industrial Microwave Thawing Frozen Food Defrosting Machine Fruits And Vegetables For Sale Thailand |

2 | Uzbekistan Industrial Meat Microwave Thawing/ Defrosting Machine For Sale Uzbekistan (Tashkent) |

3 | 300-500kg/H Tunnel Microwave Frozen Food Thawing Machine For Shrimp For Sale Uzbekistan |

4 | 50kw Microwave Mutton Thawing Unfreezing Machine For Sale With New Technology |

5 | 50kw Microwave Pig Trotters Meat Products Thawing Machine For Sale Zimbabwe |

6 | 80kw Frozen Pork Fish Prawn Chicken Thawing Euiqpment Commercial Tempering And Defrosting Equipment Meat Defrosting Machine For Sale Turkmenistan |

Tunnel Microwave Frozen Meat Mutton Processing Thawing Machine Videos