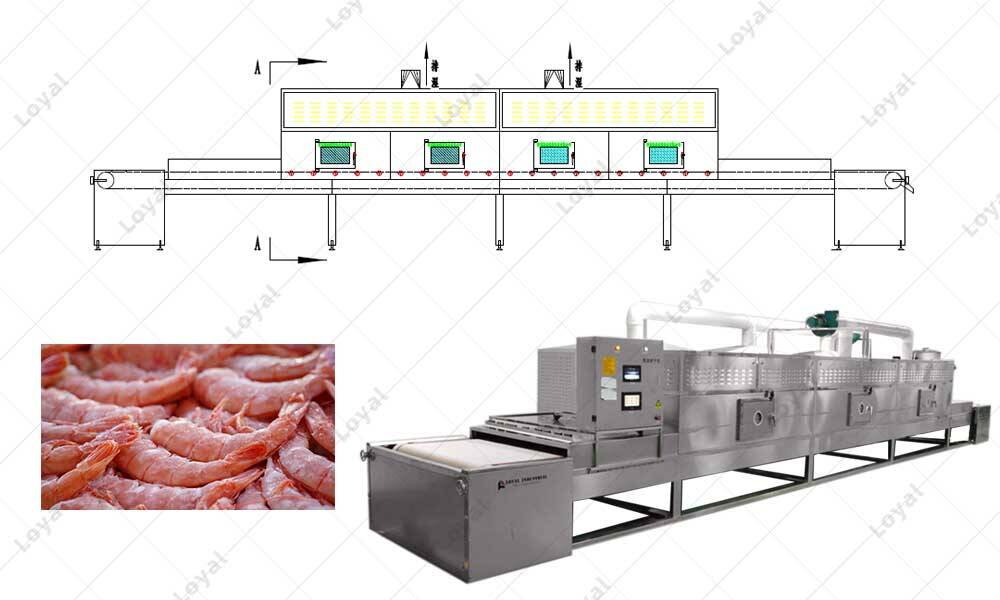

High Quality Rapidly Thawing Microwave Thawing and Sterilization Equipment for Frozen Seafood

The industrial automatic microwave Seafood thawing equipment can not only realize the freezing and processing of frozen products, but also complete thawing and curing, and also has a bactericidal effect. Compared with the traditional production thawing technology methods, the frozen Seafood microwave thawing machine use a microwave source with a frequency of 2450MHZ or 915MHZ. When heating, the microwave penetrates the material inside and outside and heats at the same time, without heat conduction, industrial microwave frozen Seafood thawing machine can be thawed with packaging, fast speed, low energy consumption, environmental protection and hygiene. Microwave Seafood thawing equipment can defrost beef, lamb, frozen meat, seafood and other products, and sterilize the process to maintain taste and color!

High Quality Rapidly Thawing Microwave Thawing and Sterilization Equipment for Frozen Seafood Specifications :

| Price | Contact the technical team of microwave drying equipment |

| Brand Name | LOYAL Microwave Thawing Equipment |

| Model Number | Microwave Thawing and Sterilization Machine for Seafood |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Thawing Equipment |

| Payment Terms | L/C,T/T, |

| Delivery Detail | 20days--35days |

| Packaging Details | Film wooden box |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sale Team | Industrial Microwave Date Drying Sterilizing Machine Team |

| Technology | 8 Years Of Microwave Technology |

High Quality Rapidly Thawing Microwave Thawing and Sterilization Equipment for Frozen Seafood Detail Introduction :

Industrial Microwave Seafood products Tempering Tunnel Oven thawing devices, frozen food(raw material) is thawed at room temperature or heated room (or hot water). Since frozen food has a higher thermal conductivity than non-frozen food, the heat transfer in the melting process is from the surface to the inside. When the thawing temperature is constant, the heat conduction of the outer layer is slower than the inner layer when the food is thawed, and the thawing time is longer, which will quickly cause the loss of juice and affect the quality of thawed food. Using microwave energy to have intense penetration at low temperature and the dielectric characteristics of ice, microwaves are used in industry to soften and adjust the temperature of frozen meat to obtain new meat-like quality and facilitate better use of meat raw materials and further processing after thawing.

How Does Frozen Seafood Defrosting Thawing Machine Equipment Work?

Put the thawed material into the thawing tank filled with water, and use the bubbles to stir the water, so as to achieve the purpose of the rapid thawing machine. There is a constant temperature pool next to the thawing pool. Water flows into the thawing machine from the constant temperature pool. As the frozen products are thawed, the products on the conveyor belt are discharged in the direction of discharge, and the water temperature in the thawing pool slowly drops. And then from the thawing pool into the constant temperature pool, so recycling, saving and environmental protection.

Technical Parameter of Microwave Thawing Equipment

Technical Parameter Of Frozen Seafood Defrosting Thawing Machine Equipment | |||

| Model | Power | Thawing Capacity | Size (LXWXH) |

| JY-25KW | 25KW | 300-400kg/h | 9x1.5x2.4m |

| JY-50KW | 50KW | 600-800kg/h | 12x1.5x2.4m |

| JY-75KW | 75KW | 1000-1200kg/h | 15x1.5x2.4m |

| JY-100KW | 100KW | 1200-1500kg/h | 18x1.5x2.4m |

What Are The Parts Of The Frozen Seafood Defrosting Thawing Machine Equipment?

| Types And Components Of Frozen Seafood Microwave Thawing Machine | |||

| Standard Control Type | Computer Automatic Control Type | ||

| 1. | Thawing Tank | The steam angle seat valve and the temperature sensor are used for linkage control | It is controlled by computer touch screen and PLC automatic execution.

|

| 2. | Lifting Device | ||

| 3. | Stainless Steel Chain Plate | ||

| 4. | Motor | ||

| 5. | Sub-tank | ||

| 6. | Gulang Air Pump | ||

| 7. | Electric Control Part | ||

What are the advantages of frozen Seafood microwave thawing machine?

1.Rapid thawing and high efficiency: Since microwaves can be heated directly into the material without conduction, it only takes 2 minutes for a piece of meat in 25 kg to rise from -15 to -4 degrees, and the thawing time is changed from "hour" to "minute".

2.Saving investment, environmental protection and pollution-free: It saves a large number of shelves and floor space required by natural defrosting, which can be defrosted in the package, reducing the requirements on sanitary environment. The waste water resources during thawing of water can be avoided to prevent the pollution of oily sewage and the loss of lipids.

3.Ensure the nutrition of materials without corruption: Because before microwave thawing, it is the process of cold storage, which avoids the mass reproduction of bacteria in the process and the material defrosting and exudation, and reduces the rate of meat loss.

4.Wide application: It can defrost beef, lamb, frozen meat, seafood and other products, and sterilize the process to maintain taste and color!

What Kind Of frozen Seafood microwave thawing machine Has Been Loyal Sold In 2021 ?

Customer Case Of Frozen Seafood Microwave Thawing Machine In 2021 | |

1 | 100kg/h Frozen Meat Microwave Thawing Machine With Tempering And Defrosting Equipment For Sale Senegal Agent |

2 | Tunnel Type Microwave Continuous Fast Frozen Seafood Thawing Machine For Sale Nigeria Factory |

3 | Tunnel Type Microwave Continuous Fast Frozen Meat Thawing Machine For Sale Burkina Faso |

4 | 50kw Industrial Microwave Frozen Seafood Thawing Machine For Sale Botswana |

| Automatic Microwave Frozen Seafood Tempering And Defrosting Equipment For Sale To America |

Customer Case Of Microwave Thawing Machine At Discount Prices In 2021 | |

1 | 800-1000kg/H frozen Seafood Oysters Microwave Industrial Microwave Tempering And Defrosting Thawing Machine For Sale Mozambique |

2 | Industrial Frozen Meat Microwave Tempering And Defrosting Equipment Defrosting Machine For Sale Austria |

3 | Duck Meat Continuous Microwave Thawing Machine For Sale Moldova Agent |

4 | 500kg/h Frozen Seafood Microwave Thawing Machine For Sale Ukraine |

5 | Automatic Frozen Food Thawing Defrosting Machine For Meat Products Freezing For Sale Singapore |

frozen Seafood microwave thawing machine