What is the production process of cereal bar?

Cereal bars are the new modern breakfast choice, providing the public with a healthy, nutritious, and convenient way of life. The market demand is very high, and the market sales of the Cereal Bar Production Line are also increasing.

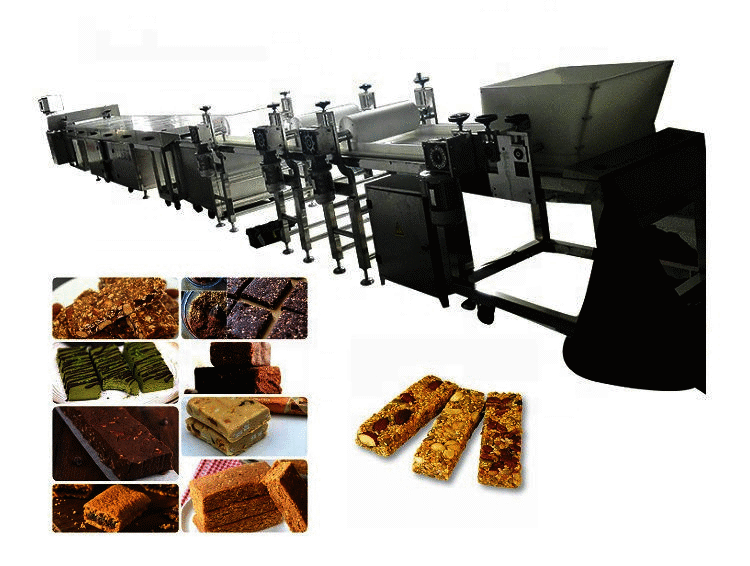

The line is mainly suitable for mixing and forming chocolate, oats, millet, peanuts, nuts, and other granules to make delicious cereal bars. It also provides manufacturers with a very advanced production and processing method. The cereal bars produced are comprehensive in nutrition and rich in taste, and always have an excellent evaluation in the market, and are generally recognized by consumers.

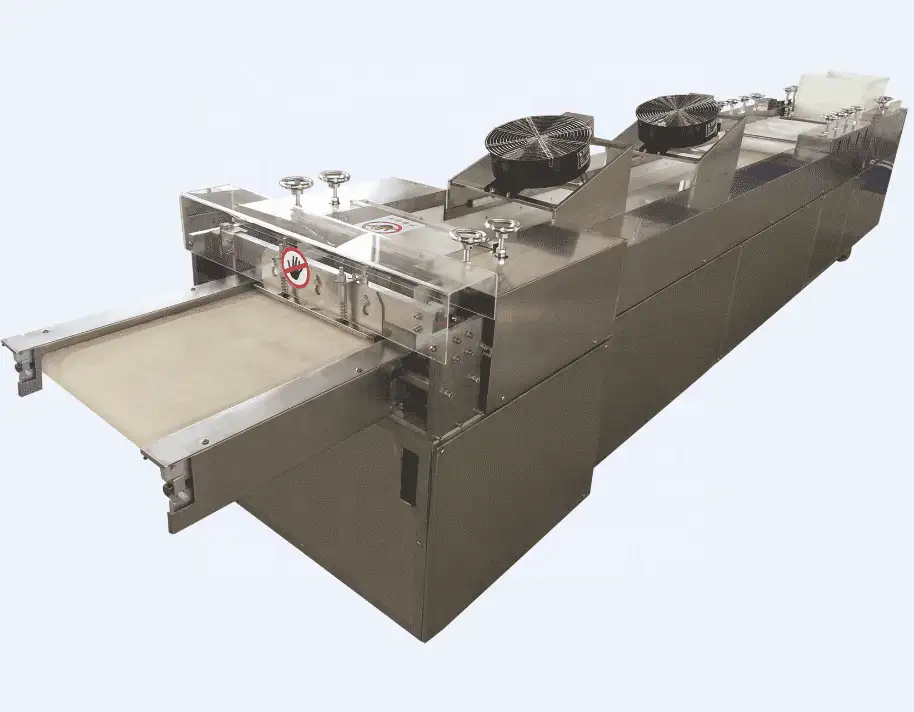

Cereal Bar Production Line adopts the best international frequency converter to control the speed and PLC control system to control the production, which is easy to operate and convenient to use, and is the ideal equipment for the modern food processing industry. Its specific process flow is shown as follows.

1. Boiling sugar: The cereal bar contains more sugar, so it is necessary to transport all kinds of sugar into the boiling sugar pot, add the right amount of water, and heat it, and stir it continuously until the sugar can all melt.

2. Mixing and stirring: The sugar and peanuts, almonds, rice, and oats are fed into the mixer, mixing the ingredients evenly.

3. Pressing into the mold: The mixed materials will be conveyed into the roller press for pressing, and the materials will be pressed into the form of tight flakes.

4. Baking: The pressed materials will be conveyed into the baking machine for high-temperature baking, and the water will be lost quickly in a short time to form a very crispy texture.

5. Cutting and forming: the baked flake form of the material needs to be cut immediately at high temperatures. Otherwise, the cereal bar will become hard and fragile after cooling. Choose different blades to cut the cereal bar into different sizes.

6. Cooling: The cut and formed cereal bar will be transported into the cooling line for cooling. After cooling, the cereal bar becomes more crispy, and the aroma of the cereal is more prominent.

7. Coating: Chocolate, butter, yogurt, and condensed milk are mixed, and the cooled cereal bars are dipped into these mixtures and then cooled and solidified, giving the cereal bars a delicious coating and a unique flavor.

Packaging: Finally, the bars are packaged in a packaging machine.

The Cereal Bar Production Line can automate the entire production process from ingredients to packaging, saving manufacturers a lot of time and effort. The equipment is so easy to operate that ordinary workers can operate it independently after simple training.

Cereal Bar Production Line is one of the best-selling production lines in the modern food processing industry. It is based on the combination of advanced technology at home and abroad, and has been developed through many reforms and innovations, and has a very advanced production process, made of food-grade stainless steel. It can process and produce cereal bars, protein bars, nutrition bars, nougat, and many other food products, which is the ideal choice for manufacturers to expand their market scale!