CE,ISO9001 Nutrition Bar Manufacturing Equipment For Puffed Rice Bars

As a professional nutrition bar manufacturing equipment manufacturer, our cereal bars production line design a good manufacturing process. The cereal bars production line can take oats, rice, black rice, sugar, nuts, corn, barley, wheat, dry fruit, raspberry, blueberry, passionflower and others as raw materials to make the cereal bar for sales. It is popular in the market because of its delicious taste, crisp texture, rich nutrition and convenient portability. It has also become the main meal replacement food for fitness people. How to make cereal bars easily? Snack bars can be round, square, semicircular or triangular in shape. Because of its delicious taste, crisp taste, nutrition, easy to carry, popular market. At the same time, it has become a major meal replacement for fitness people. Snack bar production line adopts advanced fully automated production technology. Snack bar production line has CE ISO9001 and can be used to produce puffed rice bars.

CE,ISO9001 Nutrition Bar Manufacturing Equipment For Puffed Rice Bars Specifications :

| Price | Contact Us |

| Brand Name | Loyal |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C,D/P,T/T,Western Union,MoneyGram |

| Supply Ability | 20days / Cereal Bar Production Line |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification: | CE,ISO9001,SGS,BV |

CE,ISO9001 Nutrition Bar Manufacturing Equipment For Puffed Rice Bars Detail Introduction :

Cereal bar production line was created to meet the rapidly growing demand for snickers bars, nougat, cereal bars, energy bars, fruit bars, protein bars and other products. Cereal bars can be made with oats, rice, nuts, dried fruit, chocolate, chocolate coated, cream coated, etc. Coordinate with the chocolate spray machine, it can produce all kinds chocolate compound products.

Cereal bars can be round, square, semicircular or triangular in shape. Because of its delicious taste, crisp taste, nutrition, easy to carry, popular market. At the same time, it has become a major meal replacement for fitness people. Cereal bar production line adopts advanced fully automated production technology. Cereals bars making machine has CE ISO9001 and can be used to produce puffed rice bars.

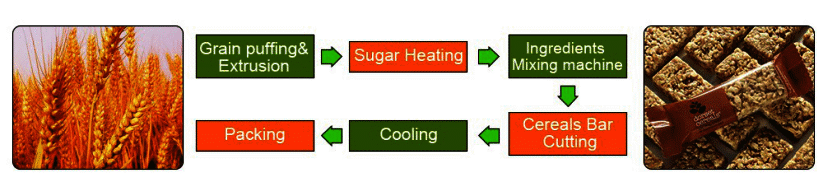

How to produce cereals bar?

CE,ISO9001 Nutrition Bar Manufacturing Equipment For Puffed Rice Bars

Grain puffing&Extrusion→Sugar Heating →Ingredients Mixing machine→Cereals Bar Cutting →Cooling→Packing

| Flow Chart Of Nutrition Bar Manufacturing Equipment | ||

| No. | Machine | Nutrition Cereals Bar Manufacturing Machine Function |

| 1 | Peanut roasting machine | Mainly used for drying and baking products. Such as peanuts, nuts, bean, maize etc. |

| 2 | Sugar Heating Machine | Sugar heating machine is made of stainless steel and has heating devices to melt sugar and other ingredients (salt, cocoa, milk, etc.). It has double layer wall which keeps the temperature of mixture. It has big heated area, high thermal efficiency, short liquid material boiling time and the heating temperature is easy to control. |

| 2 | Ingredients Mixer | Ingredient mixer is mainly used for mixing nuts, grains, syrup and other ingredients together. The inside of the hopper is made of food-grade Teflon material, which is resistant to high temperature and corrosion, so as to avoid the mixture sticking to the inside of the hopper. It is strong and durable, with long service life. And it has Thermostat to maintain mixture temperature. |

| 3 | Feeding Conveyor | To transfer raw material from mixer to cutting machine. |

| 4 | Cutting Machine with Cooling Conveyor | Cutting machine includes hopper, roller (adjust product thickness), fan (cooling products), cutter (cutting length and width), conveying (cooling products after cutting). Product width can be adjusted by the replacement tool. The frequency converter is used to control the production speed, the mixed raw material is evenly flattened by multiple rolls, and the blower can keep the mixture stable. |

| 5 | Pillow Packing Machine | The food contact parts are made of 304 stainless steel, in line with QS and GMP. Suitable for moon cake, bread, biscuits, candy, medicine, daily necessities, hardware accessories, paper boxes, plastic products or various shapes of regular solid goods. |

CEREALS BAR PRODUCTION LINE SPECIFICATIONS :

| CEREALS BAR PRODUCTION LINE SPECIFICATIONS | |

| Brand Name | Loyal |

| Material | Adopt 304 stainless steel. |

| Control system | Adopts advanced computer touch screen, plc control |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C, D/P, T/T, Western Union, Money Gram |

| Supply Ability | 20days / Cereal Bar Production Line |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification: | CE, ISO9001, SGS, BV |

Why To Choose Automatic Cereal Bar Cutting Machine?

| Advantage of Automatic Cereal Bar Cutting Machine | |

| 1 | Adopts advanced computer touch screen, plc control, variable frequency speed control and automatic deviation. |

| 2 | It adopts continuous automatic feeding, flattening,dicing and conveying. |

| 3 | The machine frame is made of standard heavy profiles through welding, ensuring sufficient rigidity and strength. The external part is made of 304 stainless steel. |

| 4 | One line can make cereal bar snack, peanut candy and so on. |

| 5 | Cut the specifications can be adjusted to meet customer’s needs of different products. |

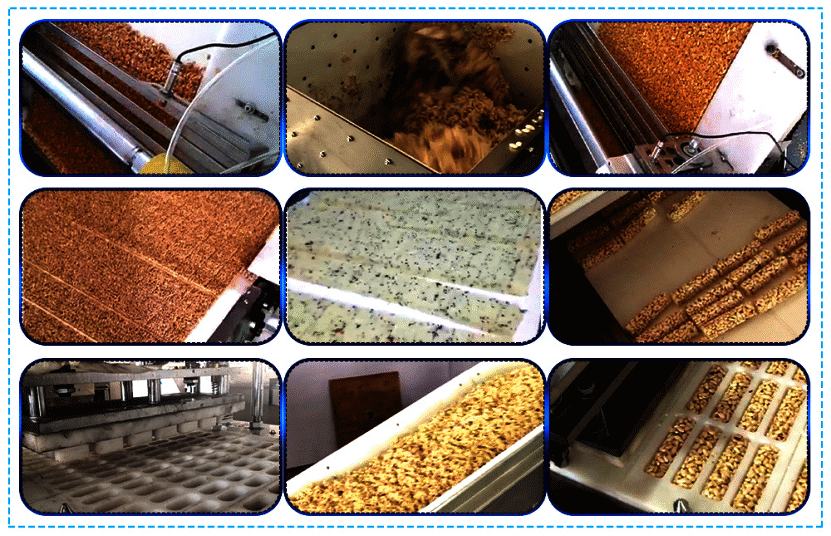

CE,ISO9001 Nutrition Bar Manufacturing Equipment For Puffed Rice Bars

| Nutrition Bar Manufacturing Equipment For Puffed Rice Bars | |||

| Machine Name | Capacity | Dimension | Characteristics |

| 1.Grain puffing machine | 100kg/h | 1320*970*960mm | With a heated area, high thermal efficiency, uniform heating, the liquid material boiling time is short, easy to control the heating temperature. |

| 2.Sugar Cooker | 100L | 1320*970*960mm | This device fitted with a thermostat, the temperature is easy to control. Applies to hospitals, preparation rooms, laboratories, research institutes, can also be used in confectionery, beverages, canned food processing units. |

| 200L | 1550*1200*1100mm | ||

| 3.Mixing Machine | 3-8kg/time | 800*1400*820mm | Material: frame channel steel spray painting treatment, pot body stainless steel, inner wall spraying Teflon, stirring shaft, stirring claw spraying Teflon. |

| 12-20kg/time | 800*1650*1600mm | ||

| 4.Granola bar cutting machine /granola bar press machine | 150-200kg/h | 1880*1110*1160mm | Microcomputer PLC control, adjustable speed and height,Error can be corrected.The horizontal knife is equipped with an air pump auxiliary pressure device, and the cutting effect is good. |

FINISHED PRODUCTS PICTURES:

Application: Peanut nougat, peanut rice cake, Peanut candy, rice candy,sesame bar, cereal bar, nuts bar Satsuma,Rice candy, Rice bar, Frozen rice candy, Sesame candy bar, Peanut brittle(peanut candy bar), Sunflower seeds candy bar, Coarse grains, Cereal bar and other molding and cutting.

Nutrition Bar Manufacturing Equipment For Puffed Rice Bars video