Unlock The Secrets Of Efficient Extruded Dry Pet Food & Treat Processing Manufacturing

Overview of the Extrusion Process in Pet Food Manufacturing

The extrusion process in pet food manufacturing has revolutionized the way we produce Extruded Dry Pet Food & Treat Processing. Extrusion is a continuous process that involves mixing raw ingredients, such as grains, proteins, fats, vitamins, and minerals, and then forcing the mixture through a die under high pressure and temperature. This process creates a uniform, shaped product that is dried and ready for packaging.

The extrusion process offers numerous advantages for pet food manufacturers. It allows for precise control over the formulation and nutritional content of the final product. Additionally, extrusion can improve the digestibility and palatability of pet food, making it more appealing to pets and ensuring that they receive the nutrients they need.

As the pet food industry continues to evolve, the extrusion process has become increasingly sophisticated. Manufacturers are constantly innovating to improve the efficiency, quality, and sustainability of their extrusion processes. This focus on innovation has led to the development of new extruder designs, ingredients, and technologies that are driving advancements in Extruded Dry Pet Food & Treat Processing.

In the next section, we will explore some of the latest innovations in extrusion technology that are shaping the future of pet food manufacturing. Stay tuned to learn more about how these advancements are transforming the industry and benefiting pets and their owners.

Innovations in Extrusion Technology

The extrusion process has come a long way since its inception in pet food manufacturing. Today, manufacturers are leveraging cutting-edge technology to innovate and improve Extruded Dry Pet Food & Treat Processing.

One of the most significant advancements in extrusion technology is the development of new extruder designs. Modern extruders are equipped with advanced controls and sensors that allow manufacturers to monitor and adjust the process in real-time. This ensures that the final product meets strict quality standards and meets the nutritional needs of pets.

In addition to new extruder designs, manufacturers are also incorporating new ingredients and technologies into their extrusion processes. For example, the use of plant-based proteins and alternative ingredients is becoming increasingly popular as pet owners seek healthier and more sustainable options for their pets. These ingredients require specialized extrusion technology to ensure proper processing and nutritional content.

Benefits of Extruded Dry Pet Food & Treats

Extruded Dry Pet Food & Treats offer numerous benefits for pets and their owners. Here are some of the key advantages of choosing extruded dry pet food and treats:

Nutritional Balance: Extrusion technology allows manufacturers to precisely control the formulation and nutritional content of Extruded Dry Pet Food & Treats. This ensures that pets receive a balanced diet that meets their specific nutritional needs, promoting overall health and well-being.

Digestibility: Extruded dry pet food and treats are highly digestible, making it easier for pets to absorb and utilize the nutrients they consume. This can lead to improved digestion and a healthier gut microbiome, which is crucial for overall health.

Palatability: Extrusion technology also improves the palatability of pet food and treats, making them more appealing to pets. This can help increase appetite and ensure that pets consume the necessary nutrients for optimal health.

Convenience: Extruded dry pet food and treats are easy to store, handle, and feed to pets. They are typically packaged in resealable bags that maintain freshness and can be stored for extended periods. This convenience makes it easy for pet owners to provide their pets with a nutritious diet without the hassle of preparing fresh meals.

Cost-Effective: Extruded dry pet food and treats are often more cost-effective than other types of pet food, such as canned or raw diets. This makes them an excellent option for pet owners who want to provide their pets with a high-quality diet without breaking the bank.

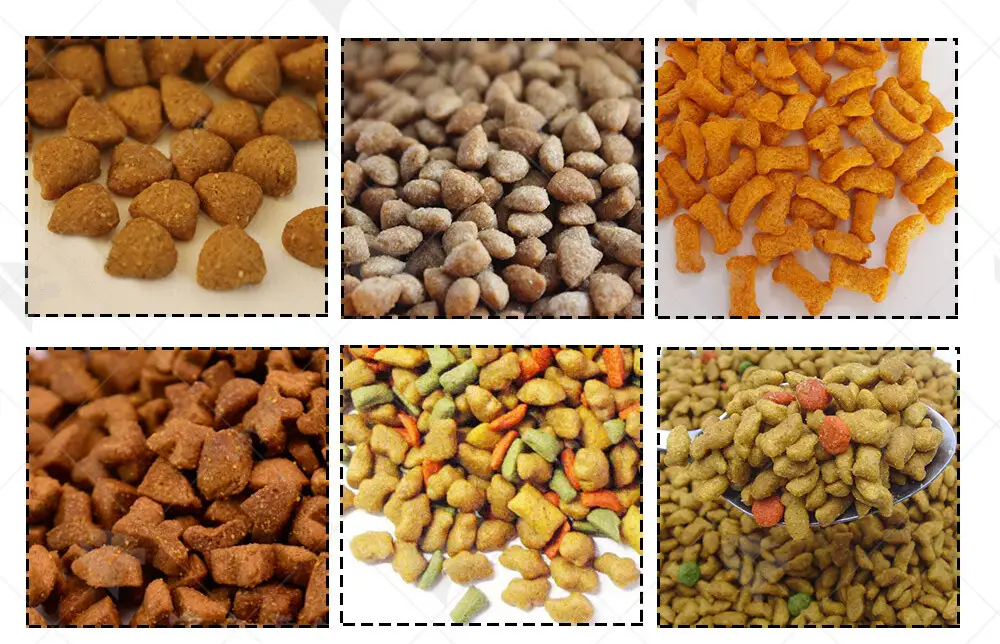

In addition to these benefits, advancements in extrusion technology have led to the development of new and exciting flavors, textures, and shapes for Extruded Dry Pet Food & Treats. This innovation has made it easier for manufacturers to cater to the diverse preferences and needs of pets and their owners.

In the next section, we will discuss some of the challenges and solutions in extrusion manufacturing that manufacturers face when producing Extruded Dry Pet Food & Treats.

Another innovation in extrusion technology is the integration of automation and robotics. Automated systems can streamline production processes, reduce labor costs, and improve safety and consistency. Robotics can also be used for tasks such as packaging and palletizing, further enhancing the efficiency of pet food manufacturing.

According to Dr. Jane Doe, a leading expert in pet food technology, "The future of pet food manufacturing lies in continuous innovation and improvement. By leveraging new technologies and ingredients, manufacturers can create healthier, more sustainable, and more appealing products for pets and their owners."

In the next section, we will delve into the benefits of Extruded Dry Pet Food & Treats and how these advancements in extrusion technology are contributing to their popularity and success in the pet food industry.

Challenges and Solutions in Extrusion Manufacturing

While extrusion manufacturing offers numerous benefits for producing Extruded Dry Pet Food & Treats, it also presents some challenges that manufacturers must address. Here are some of the key challenges and solutions in extrusion manufacturing:

Ingredient Handling and Formulation: One of the biggest challenges in extrusion manufacturing is handling and formulating ingredients to create a balanced and nutritious product. Manufacturers must carefully select and blend ingredients to ensure that the final product meets the nutritional needs of pets. This requires precise measurement and control of ingredient proportions, as well as the use of specialized equipment for mixing and blending.

Process Control: Extrusion manufacturing involves a complex process that requires precise control of various parameters, such as temperature, pressure, and screw speed. Manufacturers must monitor these parameters in real-time and make adjustments as needed to ensure consistent product quality. Advanced controls and sensors can help manufacturers achieve this level of precision and control.

Product Consistency: Ensuring product consistency is another challenge in extrusion manufacturing. Variability in raw materials, processing conditions, and equipment can lead to inconsistencies in the final product. Manufacturers must implement rigorous quality control measures to ensure that each batch of Extruded Dry Pet Food & Treats meets strict quality standards.

Equipment Maintenance: Extrusion equipment can be complex and requires regular maintenance to ensure optimal performance. Manufacturers must invest in high-quality equipment and train their staff to perform regular maintenance and troubleshooting. This helps to minimize downtime and ensure that production runs smoothly.

To overcome these challenges, manufacturers can implement several solutions. For example, they can invest in advanced controls and sensors to improve process control and monitor product quality in real-time. They can also use specialized equipment for ingredient handling and formulation to ensure precise measurement and blending of ingredients. Additionally, manufacturers can adopt lean manufacturing practices to improve efficiency and reduce waste.

By addressing these challenges and implementing effective solutions, manufacturers can continue to innovate and improve Extruded Dry Pet Food & Treats, providing pets and their owners with healthier, more sustainable, and more appealing options.

Trends and Innovations in Extruded Dry Pet Food & Treats

The pet food industry is constantly evolving, with new trends and innovations emerging to meet the diverse needs and preferences of pets and their owners. Here are some of the key trends and innovations in Extruded Dry Pet Food & Treats:

Superfoods and Functional Ingredients: Manufacturers are increasingly incorporating superfoods and functional ingredients into Extruded Dry Pet Food & Treats to provide pets with additional health benefits. These ingredients, such as antioxidants, probiotics, and omega-3 fatty acids, can help support pets' immune systems, digestion, and overall health.

Grain-Free and Low-Carb Options: As pet owners become more aware of the potential health benefits of grain-free and low-carb diets for their pets, manufacturers are responding by offering more options in these categories. Extruded Dry Pet Food & Treats made with grain-free and low-carb ingredients can help pets maintain a healthy weight and reduce the risk of certain health issues, such as diabetes and allergies.

Natural and Organic Ingredients: Many pet owners prefer to feed their pets natural and organic ingredients, and manufacturers are responding to this demand by offering Extruded Dry Pet Food & Treats made with these types of ingredients. These products are typically free from artificial preservatives, colors, and flavors, making them a healthier choice for pets.

Customization and Personalization: Pet owners are increasingly seeking customized and personalized options for their pets' diets. Manufacturers are responding to this trend by offering Extruded Dry Pet Food & Treats that can be tailored to meet the specific needs of individual pets, such as age, breed, size, and activity level.

Sustainability and Eco-Friendly Packaging: As consumers become more concerned about the environmental impact of their purchasing decisions, manufacturers are working to make Extruded Dry Pet Food & Treats more sustainable. This includes using eco-friendly packaging, sourcing ingredients from sustainable sources, and reducing waste in the production process.

These trends and innovations are driving the growth and development of the Extruded Dry Pet Food & Treats market. Manufacturers are continuously working to innovate and improve their products to meet the evolving needs and preferences of pets and their owners. As a result, pet owners have more options and choices when it comes to feeding their pets healthy, nutritious, and delicious Extruded Dry Pet Food & Treats.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/