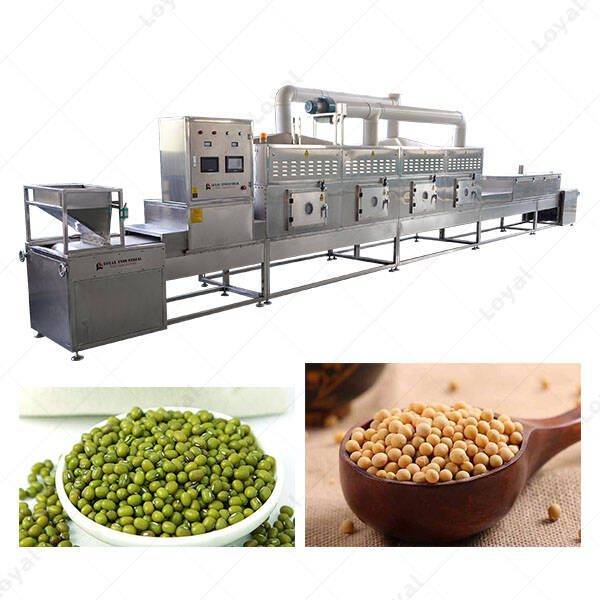

Tunnel Microwave Drying Sterilizing Machine for Grain Millet Mung Beans Buckwheat Red Beans

As one professional Tunnel Microwave Drying Sterilizing Machine manufacturer,we can offer small, medium and large microwave drying and sterilization equipment Drying Machine for sale. The Tunnel Microwave Drying Sterilizing Machine has reasonable price, reliable quality and professional service!Our company provides customers full set service .Cost accounting, Tunnel Microwave Drying Sterilizing Machinee design, Tunnel Microwave Drying Sterilizing Machine recipes, machine installation and debugging, design Tunnel Microwave Drying Sterilizing Machine request according to customer requirements. Microwave heating is the overall heating, that is, heating, the internal and external heating of the material, not the heat of the traditional heating method is conducted from the surface layer of the material.fast, efficient, safe and environmentally friendly.

Tunnel Microwave Drying Sterilizing Machine for Grain Millet Mung Beans Buckwheat Red Beans Specifications :

| Price | Microwave Drying Sterilizing Machine Technical Team |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Microwave Drying Sterilizing Machine |

| Min.Order Quantity | 1set of Microwave Drying Sterilizing Machine |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Drying Sterilizing Machine |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sales Team | Microwave Drying Sterilizing Machine Process Technology Engineer |

Tunnel Microwave Drying Sterilizing Machine for Grain Millet Mung Beans Buckwheat Red Beans Detail Introduction :

Microwave heating is the overall heating, that is, heating, the internal and external heating of the material, not the heat of the traditional heating method is conducted from the surface layer of the material.fast, efficient, safe and environmentally friendly.

The products baked by the microwave baking equipment keep its original color, the grains are puffed and crisp.

The micrwave baking macine foe dried fruit can achieve different functions such as drying, bakiing, sterilization (insecticidal) and puffing by adjusting microwave power, convey speed.

Sterilization Principle Of Industrial Microwave Equipment: | ||

| 1 | The Thermal Effect Of Microwave Energy: | Under The Action Of a Certain Intensity Of Microwave Field, Insects And Bacteria In Food Will Absorb Microwave Energy To Heat Up Due To Molecular Polarization, Thereby Denaturing Their Protein And Losing Biological Activity. |

| 2 | The Non-Thermal Effect Of Microwave Energy: | Under The Action Of a Certain Intensity Of Microwave Field, Insects And Bacteria In Food Will Absorb Microwave Energy To Heat Up Due To Molecular Polarization, Thereby Denaturing Their Protein And Losing Biological Activity. |

| 3 | Microwave Sterilization And Preservation Are The Result Of The Combined Effect Of Microwave Thermal Effect And Non-Thermal Effect: | The High-Frequency Electric Field Also Changes The Membrane Potential And Polar Molecular Structure; It Causes The Proteins And Physiologically Active Substances In The Microorganisms To Mutate And Lose Vitality Or Death. |

How To Choose Tunnel Microwave Drying Sterilizing Machine Of Different Models ?

| The model about Tunnel Microwave Drying Sterilizing Machine | |||||

| No | Model | Power | Dehydration Capacity | Sterilization Capacity | Size(L*W*H) |

| 1 | Ly-12KWSP | 12KW | 12kg/h | 120-150kg/h | 7*0.84*1.75m |

| 2 | Ly-20KWSP | 20KW | 20kg/h | 192-240kg/h | 9.4*0.84*1.75m |

| 3 | Ly-30KWSP | 30KW | 30kg/h | 300-375kg/h | 11.7*0.84*1.75m |

| 4 | Ly-40KWSP | 40KW | 40kg/h | 396-495kg/h | 10.52*1.06*1.75m |

| 5 | Ly-50KWSP | 50KW | 50kg/h | 504-630kg/h | 11.7*1.06*1.75m |

| 6 | Ly-60KWSP | 60KW | 60kg/h | 600-750kg/h | 12.86*1.06*1.75m |

| 7 | Ly-70KWSP | 70KW | 70kg/h | 696-870kg/h | 14.03*1.06*1.75m |

| 8 | Ly-80Kwsp | 80Kw | 80kg/h | 804-1000kg/h | 14.86*1.2*1.75m |

| 9 | Ly-100Kwsp | 100Kw | 100kg/h | 1000-1250kg/h | 15.2*1.2*1.75m |

| 10 | Ly-150Kwsp | 150Kw | 150kg/h | 1500-1875kg/h | 21.05*1.2*1.75m |

Technical Parameters And Price Of Tunnel Microwave Drying Sterilizing Machine

Technical Parameters And Price Of Tunnel Microwave Drying Sterilizing Machine | |||

| Type: | Drying Oven | Application: | Low-Temperature Roasting Of Whole Grains |

| Condition: | New | Place Of Origin: | Shandong, China |

| Brand Name: | Loyal | Voltage: | 380v/440v Customized |

| Power: | 20-200kw | Dimension(L*W*H): | 8640 *1200* 2200mm |

| Key Selling Points: | High Productivity | Warranty: | 1 Year |

What’s The Advantages Of Tunnel Microwave Drying Sterilizing Machine?

The Advantages Of Tunnel Microwave Drying Sterilizing Machine | ||

| 1 | Drying: | The heating rate is fast, the material is heated for a short time, and it is not easy to cause some unnecessary chemical reaction of the material. |

| 2 | Sterilization: | The microwave machine has sterilization function, the fungus, mycetes and others all can be killed. |

| 3 | Keeping fresh: | The color, taste and nutrition of food can be protected well by using the microwave machine. |

| 4 | Safe: | The machine is specially designed,the microwave will not be leaking. And the machine will not generate extra and pollution. |

| 5 | Easy to operate: | By using plc, makes the operation process simple, stable, safe and friendly. |

The Application Of Tunnel Microwave Drying Sterilizing Machine

The Application Of Tunnel Microwave Drying Sterilizing Machine | |

| Soybean Microwave Drying Sterilizing Curing Machine | Oatmeal Microwave Drying Sterilizing Curing Machine |

| Pumpkin Seeds Microwave Drying Sterilizing Curing Machine | Grain Microwave Drying Sterilizing Curing Machine |

| Millet Microwave Drying Sterilizing Curing Machine | Mung Beans Microwave Drying Sterilizing Curing Machine |

| Buckwheat Microwave Drying Sterilizing Curing Machine | Red Beans Microwave Drying Sterilizing Curing Machine |

| Pumpkin Seeds Microwave Drying Sterilizing Curing Machine | Black Sesame Microwave Drying Sterilizing Curing Machine |

Functions of Tunnel Microwave Drying Sterilizing Machine

Functions of Tunnel Microwave Drying Sterilizing Machine | |

| 1 | chemical material,medicine tablet or pill,such as watered pills,water-honey bolus,honeyed bolus,condensed pill and tibetan pill,etc. |

| 2 | all kinds of teas,herbs, flowers, green leaves,etc. |

| 3 | various dried meat, like beef, pork, chicken,duck, fish etc. |

| 4 | powder for various material,such as spices, other food additives. |

| 5 | agricultural products,such as china date,nuts,grains,peanut,etc. |

| 6 | snack food, fruit seeds, grains, peanuts, chips,etc. |

Advantages Of Microwave Drying And Sterilization Equipment Than Traditional Microwave Drying And Sterilization Equipment

Advantages Of Tunnel Microwave Drying Sterilizing Machine | |

| 1 | Fast Speed And Short Time; |

| 2 | High Product Quality; |

| 3 | Heating Evenly; |

| 4 | The Thermal Heating Process With Automatic Balance Performance; |

| 5 | Responsive And Easy To Control. |

| 6 | Compared With Other Drying Methods, It Can Save More Than 30% Energy, And It Dose Not Produceany Pllution. |

Which Market Did The Loyal Industrial Tunnel Microwave Drying Sterilizing Machine for Grain Millet Mung Beans Buckwheat Red Beans?

Customer Case Of Grain Dryer At 2021 | |

1 | 100KG/H Thaimicrowave dryer microwave drying machine for Thailand customer |

2 | 100KG/H small industrial microwave oven for sale in Uzbekistan Plant |

3 | 100KG/H microwave dryer microwave drying machine for sale in Nigeria Agent |

Customer Case Of Millet Dryer At 2021 | |

1 | microwave drying machine 100KG/H in Algerian Agent |

2 | 50KG/H industrial automatic industrial belt dryer for sale in Senegal Factory |

3 | 100KG/H industrial drying equipment in pharmaceutical industry sold in Russia Factory |

Customer Have Factory Case Of Industrial Mung Beans and Red Beans Drying Equipment At 2021 | |

1 | 200KG/H industrial microwave oven for sale in Bolivia Plant |

2 | Mozambique 150KG/H industrial drying equipment |

3 | 300KG/H industrial continuous belt dryer for sale in Pakistan Plant |

4 | Mozambique 250KG/H industrial herbs leaces tea drying equipment |