How are biscuits produced?

Cookies are a popular snack food, and there is a huge demand for them. And if you want to produce high-quality cookies, the Biscuit Production Line is the best helper.

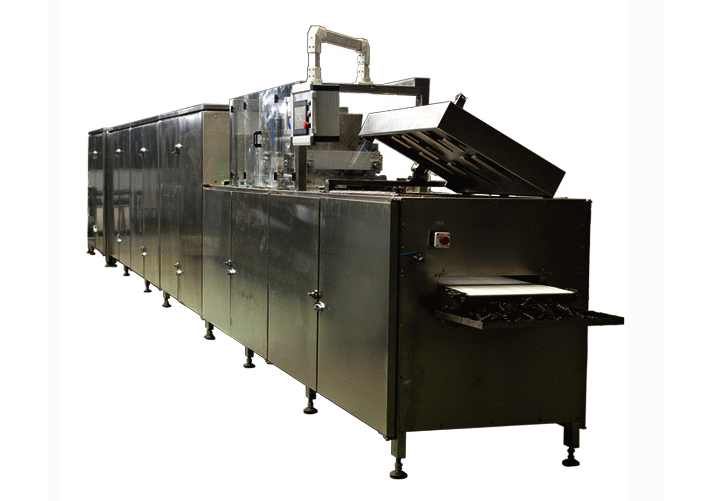

The Biscuit Production Line is professional equipment for cookie production and consists of a combination of different equipment, including baking machines, cookie forming machines, oil sprayers, high-temperature ovens, as well as cooling belts and packaging machines. The application of the equipment is very flexible, as it can be used in combination with the whole production line or only with individual equipment.

The cookies are produced from wheat flour, butter, powdered sugar, milk powder, relaxing agents and eggs, etc., and are then produced as follows.

The ingredients are first mixed according to the cookie recipe, fed into the mixer, and the appropriate amount of milk or water is added to mix the ingredients and knead them into a smooth dough.

The kneaded dough is fed into the cookie forming machine, where it is first rolled into cakes and then cut into fixed shapes, which can be produced in many different shapes, including round, square, figure, and flower shapes, by simply changing the mold.

The cut cookies are transported into the high-temperature oven, where the high temperature will make the cookies ripen quickly. In order to give the cookies a golden color, an oil sprayer is used to spray the cookies with brown oil or canola oil so that the cookies will have a more golden color and look more attractive.

The cookie is then basically finished, and the cookie is transferred into the cooling line to allow the cookie to cool naturally. The temperature of the cookies is kept at about 30 degrees Celsius, and the moisture is reduced to less than 3%, when the cookies will have the richest taste. At the same time, the cooled cookies will be packaged with higher quality, will not easily return to moisture, and will always maintain a crispy texture.

The final step in cookie production is packaging with a packaging machine.

The Biscuit Production Line can be used for various shapes and types of cookies, including chocolate cookies, soda cookies, cream cookies, sandwich cookies, ultra-thin cookies, vegetable cookies, and butter cookies. In addition, the Biscuit Production Line has many advantages that can be of great help to manufacturers.

What are the advantages of the Biscuit Production Line?

1. Food-grade stainless steel material, the equipment is durable, corrosion-resistant, wear-resistant, long service life, easy to clean.

2. Fully automatic production method, high production efficiency, and low labor cost.

3. Compact equipment structure, small footprint, the small workshop can easily manage.

4. The production process is pollution-free, waste-free, environmental protection, and energy-saving.

5. Widely used.

6. 24h continuous automatic production can be realized.

7. Simple operation and installation, easy maintenance.

Biscuit Production Line has obvious advantages and significant economic benefits. Manufacturers can get the highest return with the lowest investment, which is worthy of the trust of most manufacturers of quality production lines.