Vegetable Cookies/Sandwich Biscuit Machine 220V/380V With Siemens Motor Specifications :

| Price | Contact Us |

| Brand Name | Loyal |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C,D/P,T/T,Western Union,MoneyGram |

| Supply Ability | 20days / Biscuit Line |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification: | CE,ISO9001,SGS,BV |

Vegetable Cookies/Sandwich Biscuit Machine 220V/380V With Siemens Motor Detail Introduction :

Biscuit manufacturing machine is to add the filling material between the two piece of baked biscuit ,bread .The fillings material can be cream, jam, chocolate, bean filling, etc. We are professional manufactrer for Biscuit manufacturing machine, Our sandwiching machine adopted 304 stainless steel.

Fully automatic, Easy to clean.

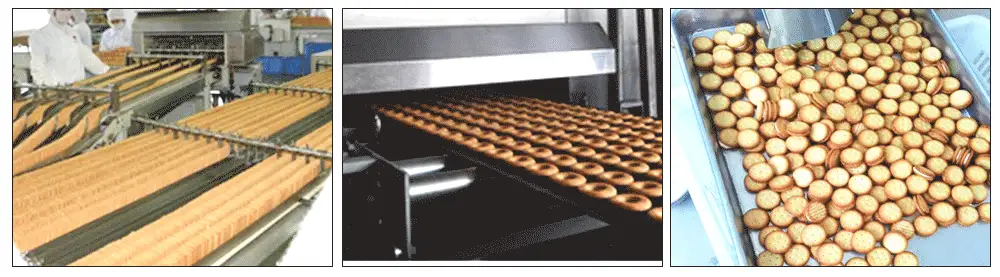

High production efficiency. Beautiful appearance.It can be connected with the packaging machine, To make filling and packaging one time automaitc, And whole line only need one worker operation. Our biscuit machine is of good quality. And the biscuit machine price is low.

DESCRIPTION OF AUTOMATIC VEGETABLE COOKIES/SANDWICH BISCUIT MACHINE 220V/380V WITH SIEMENS MOTOR

| What's the Advantage Of Biscuit Sandwiching Machine? | |

| Item No. | Advantage Of Biscuit Sandwiching Machine |

| 1 | Simple Operation, Good Stability, High Continuous Productivity And Other Characteristics, It Is An Essential Machine For The Production Of Sandwich Biscuits. |

| 2 | Stainless Steel 304 Material |

| 3 | Motor And Electrical Brands Can Be Customized According To Customer Requirements; |

| 4 | There Are Two Types Of Biscuit Sandwiches: 2+1 Type And 3+2 Type For Customers To Choose; |

Vegetable Cookies/Sandwich Biscuit Machine 220V/380V With Siemens Motor

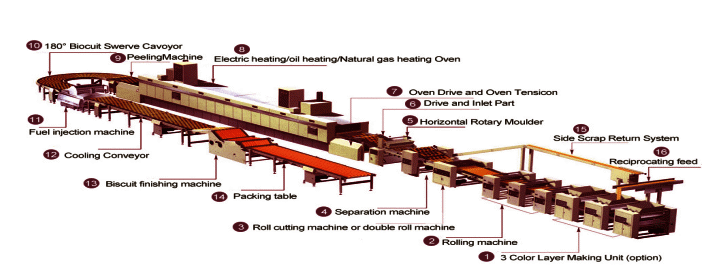

| What machines are included in the Vegetable Cookies/Sandwich Biscuit Machine production line? | ||

| S/N | ITEM | QUANTITY |

| 1 | FLOUR MIXER | 1 SET |

| 2 | ROLL CUT BISCUIT FORM MACHINE | 1 SET |

| 3 | TUNNEL OVEN(ELECTRICAL)12M LENGTH | 1 SET |

| 4 | OIL SPRAYER | 1 SET |

| 5 | NET BELT COOLING CONVEYOR | 1 SET |

| 6 | ELECTRICAL CONTROL BOX | 1 SET |

| 7. | MOLDS FOR BISCUIT | 2 SETS |

| 8. | SPARE PARTS | 1 SET |

TECHINCAL PARAMETERS OF BISCUIT MAKING MACHINE

| TECHINCAL PARAMETERS OF BISCUIT MAKING MACHINE: | |||

| 1+2 Biscuit Sandwich Machine Details | |||

| Package Type | 1 Layer*1 | 1 Layer*2 | 1 Layer*3 |

| Package Speed | 33-300pcs/Min | 33-300pcs/Min | 33-300pcs/Min |

| Package Type | 2 Layer*1 | 2 Layer*2 | 2 Layer*3 |

| Package Speed | 33-300pcs/Min | 33-130pcs/Min | 33-70pcs/Min |

| Machine Size: | 6100*1000*1600mm | ||

| Mainly Power | 7kw | ||

| Weight | 1300kg | ||

BISCUIT MACHINERY ADVANTAGE

| BISCUIT MACHINERY ADVANTAGE |

| A. Easy to operate, stable operation. |

| B. Save energy. |

| C.No noise, no pollution. |

| D. Fully automatic, saving labor and improving production efficiency. |

| E. Continuous production, no material loss, cost saving |

Flour Mixing---Moulding/Shaping--Baking---Oil Spraying---Cooling--Packing

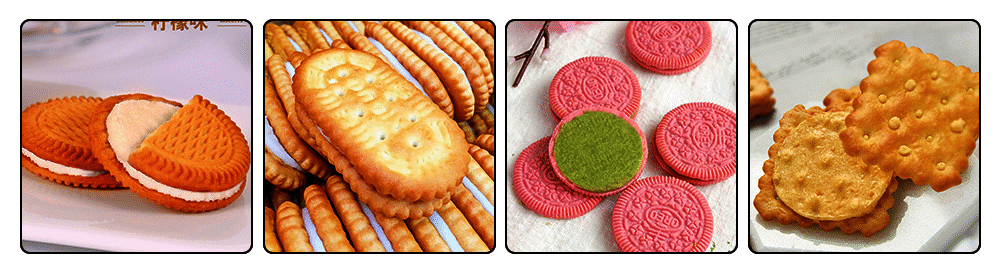

BISCUIT EXAMPLE

According to the requirement of the foreign and domestic market, our company developed and manufactured this new series of lines. The entire procedures are pipeliningwork, including the material feeding, press, shape, waste recycle, material distribute, toast, oil spray and cooling. We'l atrange the technicians to set up the equipmnents anotrain the local workers for the clients.

By changing the mold and process recipe can produce market popular high-end cookies.

Such as cream biscuits, cookies, thin biscuitssoda crackers muttidimensional, animal crackers, Discuits, vegetables, biscuits and so on

ABOUT VEGETABLE COOKIES/SANDWICH BISCUIT MACHINE 220V/380V WITH SIEMENS MOTOR

A sandwich bakery with various fillings made of sugar, fat or jam as the main raw material between two biscuits.It can be made into sandwich biscuits of various flavors, such as chocolate strawberry and other popular flavors.

Sandwich biscuits are more selective than ordinary biscuits, so the market will be larger, and the products produced by the production line will be more popular.More and more people are choosing to establish a biscuit factory to produce all kinds of sandwich biscuits.

LOYAL SERVICE

| LOYAL SERVICE |

| 1.Provide technical parameter |

| 2.Factory layout and size suggestion |

| 3.Provide general formulation |

| 4.Custom-Design service |

| 5.Professional Advice about Market, machines, materials, packing |

| 6. Suggesting professional ship agent or helping book ship as customer request. |

| 7. 24 hours online service |

Service for After-sale

| Service for After-sale |

| 1.Allocation chart as the buyer's request will be supplied. |

| 2.Operation manual will be supplied after shipment. |

| 3.One year w arrantee, life time maintenance with cost price. |

| 4.Free easy broken spare parts will be sent with container . |

| 5.First installation can be done by engineer. |

| 6.Training workers in customer's factory. |

Engineers available to service machinary overseas

| Engineers available to service machinary overseas |

| 1.Free consultation service before, during, and after sales; |

| 2.Free project planning and design services; |

| 3.Free debugging of equipment until everything is functional; |

| 4.Free management of equipments' long distance shipping; 5.Free training of equipment maintenance and operating personally; |

| 6.Free new production techniques and formulas; |

| 7. Provide 1 year complete warrantee and lifetime maintenance service |

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

30% is paid by T/T as the down payment, 70% is paid by T/T orL/C before shipment

Q:Guarantee?

Within 12 months

Why CHOOSE US?

Introduction Of Shandong Loyal Industrial Co.,Ltd.

Shandong Loyal Industrial Co.,Ltd is actually specialist manufacturer of meals equipment, snack foods machines.

22 experienced developers is helping us whose project is to research brand-new machines, design for clients, compensation equipment for customers.

We are professional manufacturer of food machine.

We mainly deal with the manufacture, research and development of the snacks food machinery. According to clients' different demands, we could offer the whole complete processing line for all kinds of expanded snacks, 2D and 3D pellet, potato chips, corn flakes, nutrition powder, pet food and so on. And our technical assistance will help clients produce high quality products all the time.

As a leading supplier of snacks food machine.

Our team are offering and selling the equipment to a lot of nations, such as Malaysia, Indonesia, Pakistan, Sri Lanka, Brazil, Europe, Australia, Africa, South America, etc., and receive good track record coming from the clients. A number of all of them become our representatives in their region.

Packing&Shipping --Biscuit Making Machine

Shipment: Within 25-30 working days from the date of receipt the down payment.

Packing by Good quality material

Shipping by 20ft container or 40ft container

Our workshop of the Biscuit Making Machine

Our company has already exported countries

Asia {Japan,Thailand, Vietnam,Indonesia, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan}

Africa { Nigeria, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe,Angole,Senegal,Libya}

Europe { Russia, Ukraine }

North America(USA)

South America { Canada, Brazil, Bolivia }

Which Market Did The Loyal Vegetable Cookies/Sandwich Biscuit Machine 220V/380V With Siemens Motor Sold To?

| Customers Have Biscuit Formula Request Of Vegetable Cookies/Sandwich Biscuit Machine 220V/380V With Siemens Motor | |

| 1 | Spain 300T/Year Industrial Salt Biscuit Making Machine |

| 2 | 1T/H Letter Biscuit Machine For Sale In Puerto Rico Plant |

| 3 | 1T/H Love Letter Biscuit Making Machine For Sale In Bolivia Factory |

| 4 | Senegal 1T/H Industrial Letter Biscuit Manufacturing Equipment |

| 5 | 1T/H Letter Biscuit Machine For Sale In Côte d'Ivoire |

| 6 | 1T/H Industrial Salt Biscuit Making Machine Sold In Russia Agent |

| Cooperated Customer Request Engineer Installation Oreo Letter Biscuit Machine At 2021 | |

| 7 | 100kg/H Industrial Letter Biscuit Production Line For Sale In Uzbekistan Factory |

| 8 | 100kg/h Industrial Automatic Letter Biscuit Machine For Sale In Senegal Agent |

| 9 | Mozambique 1T/H Automatic Biscuit making Machine |

| 10 | Bangladesh 2t/h Industrial Automatic Letter Biscuit Production Line |

| 11 | 1T/H Letter Biscuit Production Line |

| 12 | Uzbekistan 1T/H Salt Biscuit Making Machine Equipment |

| 13 | USA 1T/H Letter Biscuit Production Line |

| 14 | 50kh/h Industrial Letter Biscuit Manufacturing Plant For Sale In Nigeria Plant |

| Second- Cooperation Customers Of Automatic Letter Biscuit Making Plant At 2021 | |

| 15 | Algerian Letter Biscuit 300kg/h Production Line |

| 16 | Sudan 200kg/h Letter Biscuit Production Line |

| 17 | Moldova Small 200kg/h Oreo Letter Biscuit Machine |

| 18 | 200kg/h Letter Biscuit Machine Sold In Ukraine |

| 19 | Nigeria 150Kg/H Letter Biscuit Processing Line |

| 20 | Austria Sells Industrial Letter Biscuit Machine 100kg/h |

| Cooperated Agent Of Love Letter Biscuit Making Machine At 2021 | |

| 21 | Nigeria 150Kg/H Letter Biscuit Making Machinery |

| 22 | Vegetable Letter Biscuit Making Machine For Sale In Pakistan Factory 100kg/h |

| 23 | Austria Sells Industrial Letter Biscuit Machine 100kg/h |

| 24 | 500Kg/H Small Letter Biscuit Machine For Sale In Botswana Plant |

| 25 | Sudan 250kg/h Oreo Letter Biscuit Machine |

| 26 | Algerian Letter Biscuit 300kg/h Production Line |