304 Stainless Steel Complete Biscuit Production Line for Walnut Cake Biscuits Specifications :

| Price | Contact Us |

| Brand Name | Loyal |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C,D/P,T/T,Western Union,MoneyGram |

| Supply Ability | 20days / Industrial Tunnel Continuous Microwave Dryer |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification | CE,ISO9001,SGS,BV |

304 Stainless Steel Complete Biscuit Production Line for Walnut Cake Biscuits Detail Introduction :

In recent years, the consumption of biscuits has been on the list of most food consumption in the world. With the improvement of the mass economy, biscuits are popular with consumers for their deliciousness, rich nutrition and easy storage. The future sales will only increase. Because of this, more and more manufacturers have begun to produce biscuits. If you want to obtain high-quality biscuits. You must use a biscuit production line.

The biscuit production line, is a combination of a series of machinery for the production of biscuits.It mainly including dough mixers, biscuit forming machines, tunnel-type hot air circulation electric ovens, fuel injection machines, cooling lines, packaging machines and other equipment. In order to allow more manufacturers to elaborate. To understand the biscuit production line, Shandong Loyal Industrial Co., Ltd. will give you a detailed introduction.

304 STAINLESS STEEL COMPLETE BISCUIT PRODUCTION LINE FOR WALNUT CAKE BISCUITS DESCRIPTION

The fully automatic biscuit production line adopts advanced foreign technology. And through the continuous practice improvement of our company, we have developed this production line suitable for large, medium and small biscuit manufacturers. The characteristics of this production line

| The advantages of the Biscuit Production Line for Walnut Cake Biscuits |

| 1. Easy to operate, stable operation |

| 2. Save energy |

| 3. No noise, no pollution |

| 4. Fully automatic, saving labor and improving production efficiency. |

| 5. Continuous production, no material loss, cost saving |

HOW TO MAKE BISCUIT ?

| The detail of the Biscuit Production Line | |

| Cookies Material | Cookie Making Machine |

| The main ingredients of cookies | Eggs, flour, butter, sugar, dried fruits, etc. |

| Types of cookies | Butter Cookies ,Chocolate Cookies ,Cranberry Milk Cookies, Chocolate Soft Cookies, Cheese Cake Cookies ,Three Squeeze Cookies, Purple Potato Cookies |

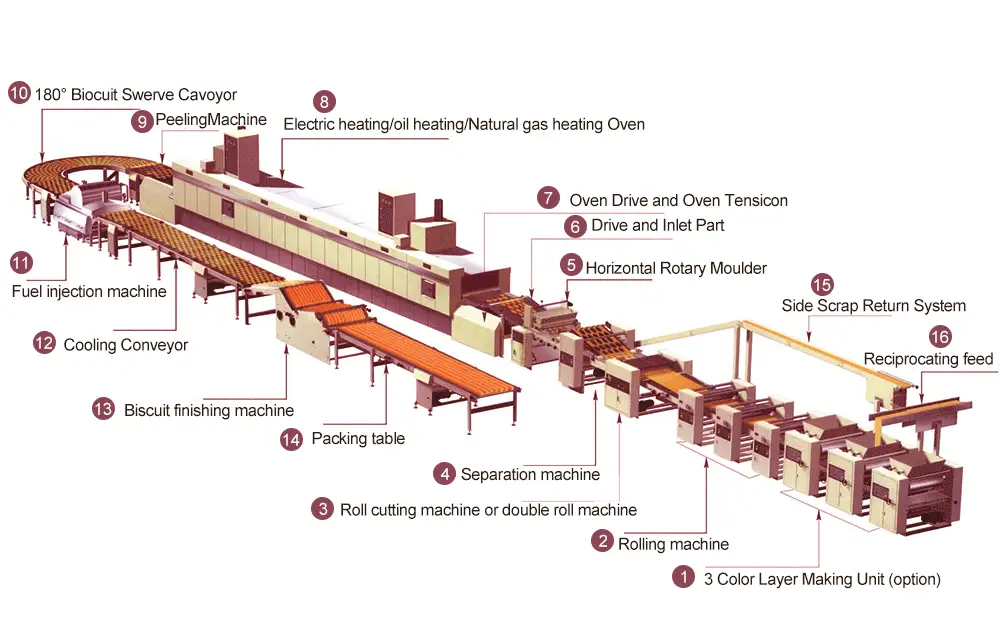

304 STAINLESS STEEL COMPLETE BISCUIT PRODUCTION LINE FOR WALNUT CAKE BISCUITS FLOW CHART:

TECHNICAL PARAMETERS OF 304 STAINLESS STEEL COMPLETE BISCUIT PRODUCTION LINE FOR WALNUT CAKE BISCUITS

| TECHNICAL PARAMETERS OF 304 STAINLESS STEEL COMPLETE BISCUIT PRODUCTION LINE FOR WALNUT CAKE BISCUITS | |||||

| Host Model | LY-225 | LY-280 | LY-400 | LY-600 | LY-800 |

| Power and voltage | customize | customize | customize | customize | customize |

| Installed Capacity | 28.5KW | 55KW | 110KW | 220kw(gas type 25kw) | customize |

| Heating Source | Electrical | Electrical | Electrical, Gas | Electrical,Gas | Electrical, Gas |

| Baking temperature | 200-300℃ | 200-300℃ | 200-300℃ | 200-300℃ | 200-300℃ |

| Production capacity | 50~60Kg/h | 100kg/h | 150-200Kg/h | 400-500kg/h | 600-900kg/h |

WHATS THE 304 STAINLESS STEEL COMPLETE BISCUIT PRODUCTION LINE FOR WALNUT CAKE BISCUITS INCLUDING?

| WHATS THE 304 STAINLESS STEEL COMPLETE BISCUIT PRODUCTION LINE FOR WALNUT CAKE BISCUITS INCLUDING? | ||

| Name | Decription | |

| 1 | Mixer | The dough mixer is a machine that mixes flour and water or other ingredients into dough. It is widely used in making various pastries, biscuits, bread, steamed bread and other doughs. |

| 2 | Biscuit Forming Machine | Generally adopts a new type of biscuit machine that combines roll printing, roll cutting, stacking, extrusion, and wire cutting. The thickness of the dough sheet is controlled by an electronic alarm.So that the operator can correct the deviation in time and reduce defective products. Ensure the smooth progress of production. |

| 3 | Biscuit Drying Oven | Can make the baked mature biscuits of good quality. And can effectively ensure that the color of the whole batch of biscuits is even and consistent. |

| 4 | Oil Sprayer | Can evenly spray cooking oil on the baked biscuits, making the biscuits richer in color and full-bodied. |

| 5 | Cooling Line | Allow the finished biscuits to cool down so that they can be better packaged. |

| 6 | Packaging Machine | The can strictly control the spread of the biscuits to make the thickness and weight of the biscuits consistent. It can realize automatic blister packaging, weighing, bagging, sealing, etc.So that the biscuits are not polluted by human hands. And the production is hygienic and efficient. . |

The biscuit production line produced by Shandong Loyal Industrial Co., Ltd. is of very high quality and has a very high reputation in the industry. Our professionalism is unparalleled in the industry. We support our customers by providing flexible and efficient solutions. Our customers are very competitive in the challenging food market.

It is precisely because of this that our biscuit production line has gained loyal customers from all over the world. The production line has given a satisfactory answer in terms of production quality. The biscuit produced is of stable quality, rich in taste, and less waste. It is deeply loved by customers.

The most important thing is that the production line is easy to operate and high in production efficiency.

The biscuit production line is the key to stand out in the fiercely competitive biscuit industry. We are confident enough to help you. If you need it, please contact us and we will serve you wholeheartedly!

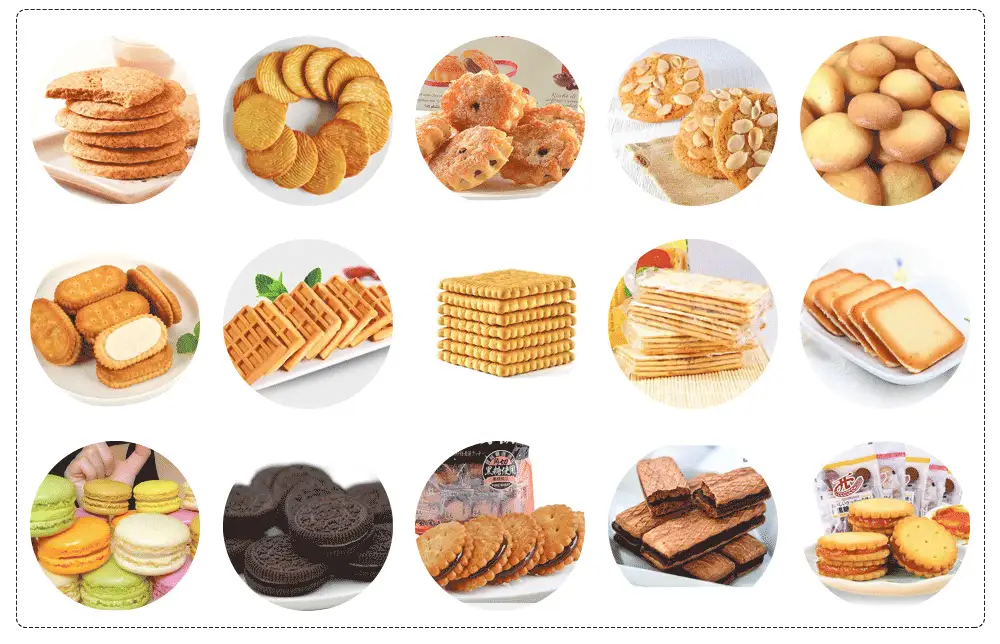

BISCUITS SHOW 304 STAINLESS STEEL COMPLETE BISCUIT PRODUCTION LINE FOR WALNUT CAKE BISCUITS

ADVNTAGES OF LOYAL’S BISCUIT MAKING MACHINE

| Advantage Of Biscuit Making Machine | |

| 1 | The Biscuit Machine Occupies a Small Area And Consumes Less, Small Workshop Can Also Start Production Easily. |

| 2 | Biscuit Machine There Are Many Types Of Molds And Product Designs. One Machine Can Produce Crispy Biscuits, Tough Biscuits, Chocolate Biscuits, Such As Cream Biscuits, Sandwich Biscuits, Soda Biscuits, Animal Biscuits, Vegetable BiscuitsBiscuit Making Machine Can Produce 24 Hours Continuously Every Day. |

| 3 | Fully Automatic Small Biscuit Machine Requires Fewer Workers, 2-3 Workers Can Complete The Whole Process From Raw Material Mixing To Packaging,The Operation Is Simple, And The Workers Can Easily Operate The Machine After Training. |

| 4 | No Industrial Pollution And No Waste. |

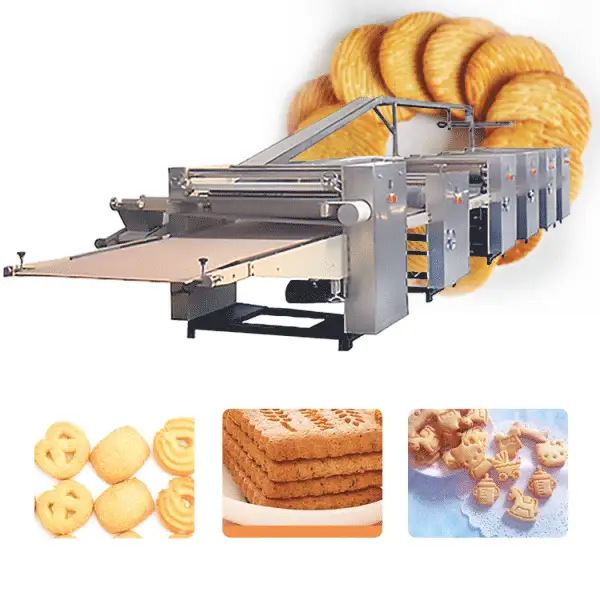

MACHINE PHOTOS Of AUTOMATIC 304 STAINLESS STEEL COMPLETE BISCUIT PRODUCTION LINE FOR WALNUT CAKE BISCUITS

LOYAL SERVICE

Service for Pre-sale

| Service for Pre-sale |

| 1.Provide technical parameter |

| 2.Factory layout and size suggestion |

| 3.Provide general formulation |

| 4.Custom-Design service |

| 5.Professional Advice about Market, machines, materials, packing |

| 6. Suggesting professional ship agent or helping book ship as customer request. |

| 7. 24 hours online service |

Service for After-sale

| Service for After-sale |

| 1.Allocation chart as the buyer's request will be supplied. |

| 2.Operation manual will be supplied after shipment. |

| 3.One year w arrantee, life time maintenance with cost price. |

| 4.Free easy broken spare parts will be sent with container . |

| 5.First installation can be done by engineer. |

| 6.Training workers in customer's factory. |

Engineers available to service machinary overseas

| Engineers available to service machinary overseas |

| 1.Free consultation service before, during, and after sales; |

| 2.Free project planning and design services; |

| 3.Free debugging of equipment until everything is functional; |

| 4.Free management of equipments' long distance shipping; |

| 5.Free training of equipment maintenance and operating personally; |

| 6.Free new production techniques and formulas; |

| 7. Provide 1 year complete warrantee and lifetime maintenance service |

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

30% is paid by T/T as the down payment, 70% is paid by T/T orL/C before shipment

Q:Guarantee?

Within 12 months

Q:Contact Information?

Any question please contact us! Welcome to Jinan.

2021 Customer Order Biscuit Production Line Form:

| Customers Have Biscuit Formula Request Of Letter Biscuit Production Line | |

| 1 | Spain 300T/Year Industrial Salt Biscuit Making Machine |

| 2 | 1T/H Letter Biscuit Machine For Sale In Puerto Rico Factory |

| 3 | 1T/H Love Letter Biscuit Making Machine For Sale In Bolivia Agent |

| 4 | Senegal 1T/H Industrial Letter Biscuit Manufacturing Equipment |

| 5 | 1T/H Letter Biscuit Machine For Sale In Côte d'Ivoire Agent |

| 6 | 1T/H Industrial Salt Biscuit Making Machine Sold In Russia Plant |

| Cooperated Customer Request Engineer Installation Oreo Letter Biscuit Machine At 2021 | |

| 7 | 100kg/H Industrial Letter Biscuit Production Line For Sale In Uzbekistan |

| 8 | 100kg/h Industrial Automatic Letter Biscuit Machine For Sale In Senegal Plant |

| 9 | Mozambique 1T/H Automatic Biscuit making Machine |

| 10 | Bangladesh 2t/h Industrial Automatic Letter Biscuit Production Line |

| 11 | 1T/H Letter Biscuit Production Line |

| 12 | Uzbekistan 1T/H Salt Biscuit Making Machine Equipment |

| 13 | USA 1T/H Letter Biscuit Production Line |

| 14 | 50kh/h Industrial Letter Biscuit Manufacturing Plant For Sale In Nigeria Agent |

| Second- Cooperation Customers Of Automatic Letter Biscuit Making Plant At 2021 | |

| 15 | Algerian Letter Biscuit 300kg/h Production Line |

| 16 | Sudan 200kg/h Letter Biscuit Production Line |

| 17 | Moldova Small 200kg/h Oreo Letter Biscuit Machine |

| 18 | 200kg/h Letter Biscuit Machine Sold In Ukraine Factory |

| 19 | Nigeria 150Kg/H Letter Biscuit Processing Line |

| 20 | Austria Sells Industrial Letter Biscuit Machine 100kg/h |

| Cooperated Agent Of Love Letter Biscuit Making Machine At 2021 | |

| 21 | Nigeria 150Kg/H Letter Biscuit Making Machinery |

| 22 | Vegetable Letter Biscuit Making Machine For Sale In Pakistan 100kg/h |

| 23 | Austria Sells Industrial Letter Biscuit Machine 100kg/h |

| 24 | 500Kg/H Small Letter Biscuit Machine For Sale In Botswana Factory |

| 25 | Sudan 250kg/h Oreo Letter Biscuit Machine |

| 26 | Algerian Letter Biscuit 300kg/h Production Line |