Industry Multi-function Automatic Biscuit Production Line, Biscuit Making Machine Specifications :

| Price | Contact Us |

| Brand Name | Loyal |

| Place of Origin | Shandong, China |

| Min.Order Quantity | 1 set |

| Payment Terms | L/C,D/P,T/T,Western Union,MoneyGram |

| Supply Ability | 20days / Biscuit Line |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' requirement |

| Certification: | CE,ISO9001,SGS,BV |

Industry Multi-function Automatic Biscuit Production Line, Biscuit Making Machine Detail Introduction :

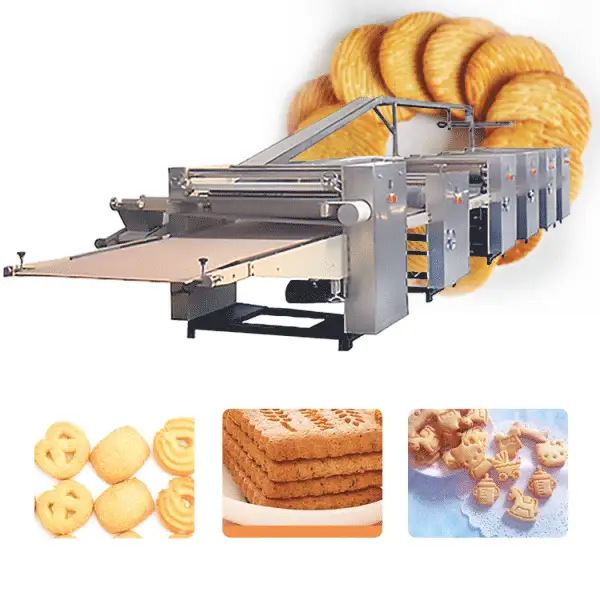

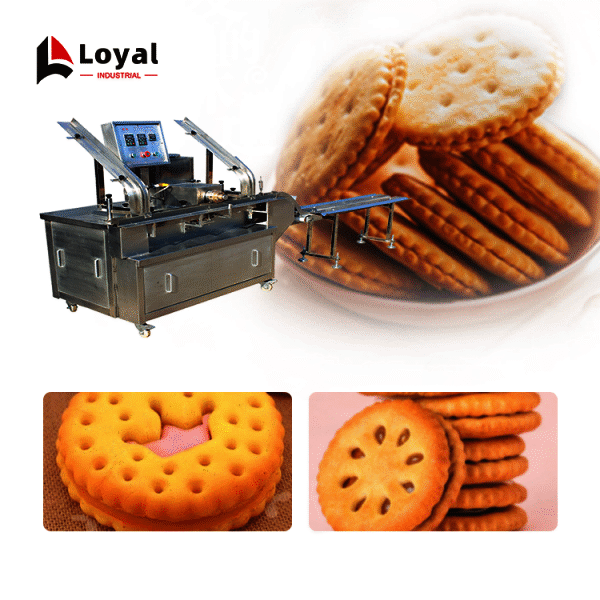

Fully Automatic biscuit manufacturing machine can make many different type of biscuits. Such as cream biscuit, sandwiching biscuit,soda cracker biscuit,vegetable biscuit etc., There are diversify heating source for your operation (electric, gas, fuel oil) .

A Biscuit Production Line is a highly specialized industrial setup designed for the mass production of biscuits, encompassing various types of cookies and similar baked goods. This production line integrates multiple stages of biscuit making, including dough mixing, sheeting, molding, baking, and cooling, followed by packaging. Modern biscuit production lines are equipped with advanced automation technology to ensure efficiency, consistency, and quality.

As one professional biscuit manufacturing machine manufacturer,we can offer small, medium and large biscuit production lines . The biscuit making machine has reasonable price, reliable quality and professional service!Our company provides customers full set service .Cost accounting, machine design, cookie recipes, machine installation and debugging, design cookie molds according to customer requirements.You can rest assured of our prices,our biscuit machine price is reasonable.

APPLICATIONS OF INDUSTRY MULTI-FUNCTION AUTOMATIC BISCUIT PRODUCTION LINE

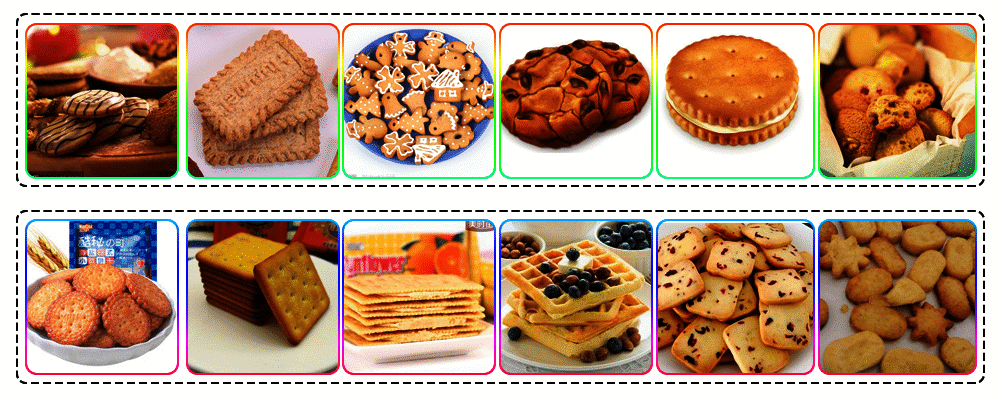

Our biscuit making production line can product:

Every kinds of biscuit in different shape and taste. Such as ~

Soft Biscuit ,Hard Biscuit Cream biscuit, layer biscuit, soda cracker, calcium biscuit, multi-vitamin biscuit, vegetable biscuit, sugar-free biscuits,Baby Biscuit,Milk Biscuit,Chocolate bisucit,etc.

TECHNICAL PARAMETERS OF INDUSTRY MULTI-FUNCTION AUTOMATIC BISCUIT PRODUCTION LINE

| TECHNICAL PARAMETERS OF INDUSTRY MULTI-FUNCTION AUTOMATIC BISCUIT PRODUCTION LINE | |||||

| Host Model | LY-225 | LY-280 | LY-400 | LY-600 | LY-800 |

| Power and voltage | customize | customize | customize | customize | customize |

| Installed Capacity | 28.5KW | 55KW | 110KW | 220kw(gas type 25kw) | customize |

| Heating Source | Electrical | Electrical | Electrical, Gas | Electrical,Gas | Electrical, Gas |

| Baking temperature | 200-300℃ | 200-300℃ | 200-300℃ | 200-300℃ | 200-300℃ |

| Production capacity | 50~60Kg/h | 100kg/h | 150-200Kg/h | 400-500kg/h | 600-900kg/h |

HOW DOES THE BISCUIT MACHINE PRODUCE BISCUITS?

The main raw material of biscuit is wheat flour, in addition to sugar, starch, oil, dairy products, eggs, essence, leavening agent auxiliary materials. The above raw and auxiliary materials are made into dough by the dough mixer, which is rolled into dough sheets by the rolling mill, pressed into cake billet by the molding machine, and finally baked in the oven and cooled into crisp and delicious biscuits.

According to the formulation and production process of different cookies can be divided into two categories, that is, Hard cookies and soft cookies.

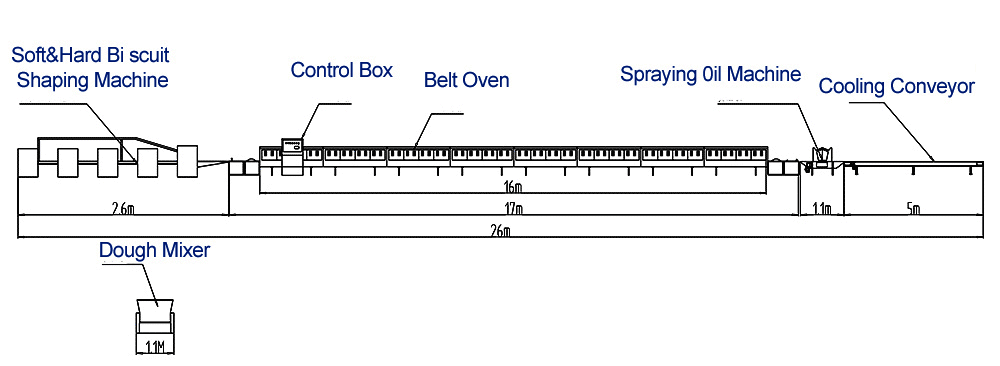

Flow Chart Of Automatic Biscuit Making Production Line

Flour Mixing---Soft Biscuit Forming---Biscuit Baking---Oil Spraying---Biscuit Stacking ---Cooling And Sterilization ---Biscuit Packing

INDUSTRY MULTI-FUNCTION AUTOMATIC BISCUIT PRODUCTION LINE, BISCUIT MAKING MACHINE

WHAT WE CAN OFFER OF INDUSTRY MULTI-FUNCTION AUTOMATIC BISCUIT MAKING MACHINE?

| WHAT WE CAN OFFER OF INDUSTRY MULTI-FUNCTION AUTOMATIC BISCUIT MAKING MACHINE? | |

| Biscuit Machine Name: | Quantity |

| Full Steel Flour Press | 2set |

| Scraper Conveyor | 1set |

| Soft Biscuit Forming Machine | 1set |

| Sugar and Salt sprayer Machine | 1set |

| Inlet Oven Machine | 1set |

| Baking Tunnel Oven-GAS | 42M |

| Outlet Oven Machine | 1set |

| Peeling Machine | 1set |

| Oil Sprayer | 1set |

| 180°Swerving Machine | 1set |

| Biscuit Cooling and Conveying Machine | 25m |

| Stacking Machine | 1set |

| Packing Table | 8M |

| Control Cabinet | 1 sets |

| Biscuit Mould | 2 sets |

LOYAL SERVICE

Service for Pre-sale

| Service for Pre-sale |

| 1.Provide technical parameter |

| 2.Factory layout and size suggestion |

| 3.Provide general formulation |

| 4.Custom-Design service |

| 5.Professional Advice about Market, machines, materials, packing |

| 6. Suggesting professional ship agent or helping book ship as customer request. |

| 7. 24 hours online service |

| Service for Pre-sale |

| 1.Allocation chart as the buyer's request will be supplied. |

| 2.Operation manual will be supplied after shipment. |

| 3.One year w arrantee, life time maintenance with cost price. |

| 4.Free easy broken spare parts will be sent with container . |

| 5.First installation can be done by engineer. |

| 6.Training workers in customer's factory. |

Service for After-sale

Engineers available to service machinary overseas

| Service for After-sale |

| 1.Free consultation service before, during, and after sales; |

| 2.Free project planning and design services; |

| 3.Free debugging of equipment until everything is functional; |

| 4.Free management of equipments' long distance shipping; |

| 5.Free training of equipment maintenance and operating personally; |

| 6.Free new production techniques and formulas; |

| 7. Provide 1 year complete warrantee and lifetime maintenance service |

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

30% is paid by T/T as the down payment, 70% is paid by T/T orL/C before shipment

Q:Guarantee?

Within 12 months

Q:Contact Information?

Any question please contact us! Welcome to Jinan.

Our Advantages

15 years history on food machinery.22 experienced engineers is working for us whose job is to research new machines, design for clients,24Hours’service and 15 after sales service personnels help our clients to solve all the errors of our machines as soon as possible

Novel design, compact structure, high degree of automation,complete from feeding calendering, forming, waste recycling, drying, oil injection, cooling, all at once

Provide users with hundreds of molds and dozens of process formulas.If you have any questions, please contact us, we will treat it with integrity.Looking forward to getting in touch with you.

Packing&Shipping --Biscuit Making Machine

Shipment: Within 25-30 working days from the date of receipt the down payment.

Packing by Good quality material

Shipping by 20ft container or 40ft container

Introduction Of Our Factory--Biscuit Making Machine

Shandong Loyal Industrial Co., Ltd,which is a professional food machine manufacturer with more than 15 years' experiences.

We located at Jinan,China,---the beautiful Spring city at north of china.

LOYAL’S FACTORY PHOTO

22 experienced engineers is working for us whose job is to research new machines, design for clients, commission equipments for clients.24 Hours' service and 15 after sales service personnels help our clients to solve all the errors of our machines as soon as possible. With the development of our company,our products have been exported to more than eighty countries,such as the United States,,Poland,Canada,Mexico,Brazil and so We are committed to improve our service and keep the good quality in order to satisfy every customer.

THE FOLLOWING IS LOYAL HONOR

Our company has already exported countries

Asia {Japan,Thailand, Vietnam,Indonesia, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan}

Africa { Nigeria, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe,Angole,Senegal,Libya}

Europe { Russia, Ukraine }

North America(USA)

South America { Canada, Brazil, Bolivia }

2021 Customer Order Letter Biscuit Production Line Form:

Our Letter Biscuit Production Line is summed up by a number of 25 technical engineers who have more than ten years of experience. Loyal love letter biscuit making machine has a number of letter biscuit project technology patents, which can provide you with the most detailed formula and process documents, which can save letter biscuit manufacturing plant cost while improving good development in the biscuit manufacturing industry.

| Customers Have Biscuit Formula Request Of Letter Biscuit Production Line | |

| 1 | Spain 300T/Year Industrial Salt Biscuit Making Machine |

| 2 | 1T/H Letter Biscuit Machine For Sale In Puerto Rico Plant |

| 3 | 1T/H Love Letter Biscuit Making Machine For Sale In Bolivia Factory |

| 4 | Senegal 1T/H Industrial Letter Biscuit Manufacturing Equipment |

| 5 | 1T/H Letter Biscuit Machine For Sale In Côte d'Ivoire Factory |

| 6 | 1T/H Industrial Salt Biscuit Making Machine Sold In Russia Agent |

| Cooperated Customer Request Engineer Installation Oreo Letter Biscuit Machine At 2021 | |

| 7 | 100kg/H Industrial Letter Biscuit Production Line For Sale In Uzbekistan |

| 8 | 100kg/h Industrial Automatic Letter Biscuit Machine For Sale In Senegal Fctory |

| 9 | Mozambique 1T/H Automatic Biscuit making Machine |

| 10 | Bangladesh 2t/h Industrial Automatic Letter Biscuit Production Line |

| 11 | 1T/H Letter Biscuit Production Line |

| 12 | Uzbekistan 1T/H Salt Biscuit Making Machine Equipment |

| 13 | USA 1T/H Letter Biscuit Production Line |

| 14 | 50kh/h Industrial Letter Biscuit Manufacturing Plant For Sale In Nigeria Agent |

| Second- Cooperation Customers Of Automatic Letter Biscuit Making Plant At 2021 | |

| 15 | Algerian Letter Biscuit 300kg/h Production Line |

| 16 | Sudan 200kg/h Letter Biscuit Production Line |

| 17 | Moldova Small 200kg/h Oreo Letter Biscuit Machine |

| 18 | 200kg/h Letter Biscuit Machine Sold In Ukraine Plant |

| 19 | Nigeria 150Kg/H Letter Biscuit Processing Line |

| 20 | Austria Sells Industrial Letter Biscuit Machine 100kg/h |

| Cooperated Agent Of Love Letter Biscuit Making Machine At 2021 | |

| 21 | Nigeria 150Kg/H Letter Biscuit Making Machinery |

| 22 | Vegetable Letter Biscuit Making Machine For Sale In Pakistan 100kg/h |

| 23 | Austria Sells Industrial Letter Biscuit Machine 100kg/h |

| 24 | 500Kg/H Small Letter Biscuit Machine For Sale In Botswana Factory |

| 25 | Sudan 250kg/h Oreo Letter Biscuit Machine |

| 26 | Algerian Letter Biscuit 300kg/h Production Line |