High Capacity Bugle Snack Food Making Machine Food Bugles Chips Machinery Production Line

As the professional Bugle Snack Food Making Machine supplier, our fried snack machine design good manufacturing process. High Capacity Bugle Snack Food Making Machine Food Bugles Chips Machinery Production Line take wheat flour, corn flour, potato starch and others as raw materials, to make the crispy fried chips snacks in different shape for sale, such as long stick, square chips, screws etc. Fried bugle chips production line uses double screw extruding technique to replace the traditional steam boiling process. The whole bugles chips machinery production line includes mixing, cooking , extruding, and shaping process, no needing boiler, with simple process, high efficiency and little pollution.This fried bugle chips making machine has the functions of self-cleaning, multi-functional, high efficiency, easy operation, and high capacity, which is suitable for newly snacks food production lines and expanded production scale factories with production experience.

High Capacity Bugle Snack Food Making Machine Food Bugles Chips Machinery Production Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Certification | CE ISO9001 |

| MOQ | 1 set/Bugles Chips Machinery Production Line |

| Keywords | Bugles/Salad Chips Machinery Production Line |

| Voltage | 380V/50HZ Three Phase, 440v, 415v, etc |

| Certification | CE ISO9001 |

| Material | Stainless Steel 304 |

| Automation | Fully Automatic |

| After-sales Service Provided | Engineers available to service machinery overseas |

High Capacity Bugle Snack Food Making Machine Food Bugles Chips Machinery Production Line Detail Introduction :

This Fried bugle chips production line achieves mechanized process for traditional handmade wheat food. It not only continues crispy and non-greasy taste, but realizes the infinite innovation of raw material. Only twin screw extruder can accomplish the process of mixing, cooking, puffing, shaping etc. If equip with sala cutting machine, frying machine, we can produce salad chips, crust and other 2D fried snacks food. The fried bugle chips machine equips with pattern processing machine, compound shaping machine, frying machine, we can produce bugles, pillow, goldfish and other 3D fried snacks food For sale.

Fried bugle chips production line uses double screw extruding technique to replace the traditional steam boiling process. It includes mixing, cooking, extruding, and shaping process, no needing boiler, with simple process, high efficiency and little pollution. The raw materials can be rice powder, corn powder, wheat flour individually or their mixture. Only by changing the moulds, shaping or cutting machine, the shapes can be various: sticks, square sheet rib chips, diamond chips, wavy chips, pillow shapes and bugles etc. The taste is good and no greasiness.

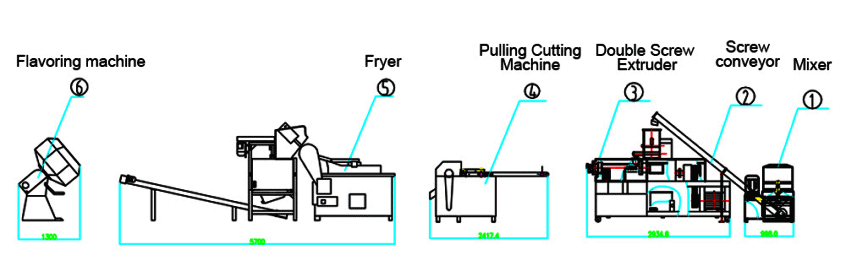

FLOW CHART OF FOOD BUGLES CHIPS MACHINERY PRODUCTION LINE:

Mixer--Screw Conveyor--Double screw Extruder--Cutter--Continuous Fryer--Deoiling Machine--Flavoring Line

Equipment List Of The Industrial Fried Bugle Chips Production Line | |

| Machine Name | Function |

| Mixer | Mix The Material, Make Full Mix |

| Screw Conveyor | Conveying The Material Into The Extruder |

| Double Screw Extruder | Extruding & Puffing |

| Cutter | Cut Off The Products |

| Continuous Fryer | Fryed The Product |

| Deoiling Machine | Make The Products Deoiled |

| Flavoring Line | Mix The Seasoning With Products |

TECHNICAL REFERENCE PARAMETER OF HIGH CAPACITY BUGLE SNACK FOOD MAKING MACHINE :

Technical Parameter Of Full Automatic Fried Bugle Salad Chips Production Line | |||||

Model | Installed capacity | Power | Output capacity | Size (L*W*H) | Price($) For Reference |

LY65 | 88KW | 65KW | 150-200kg/h | 18000x2000x4000mm | 16,500-18,900 |

LY70 | 126KW | 82KW | 200-250kg/h | 22000x2000x4000mm | 22,500-26,500 |

LY70L | 126KW | 82KW | 250-350kg/h | 26000x2000x4000mm | 32,500-38,500 |

Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz.

We can make it according to customers' local voltage according to different countries.

SAMPLE PICTURES OF FRIED BUGLE CHIPS:

The raw materials can be rice powder, corn powder, wheat flour individually or their mixture. Only by changing the moulds, shaping or cutting machine, the shapes can be various, like sticks, square sheet rib chips, diamond chips, wavy chips, pillow shapes and bugles etc. The taste is savory and not greasy.

Fried Bugles Chips Production Line uses wheat flour as main material which are extruded, punched into triangle, fish shapes, and then fried and flavored. Such snacks with crispy taste, rich nutrition and digestible structure are very popular with many people all over the world. And most important, the waste punching chip can be reused after grinded into powder, which can greatly reduce the production cost.

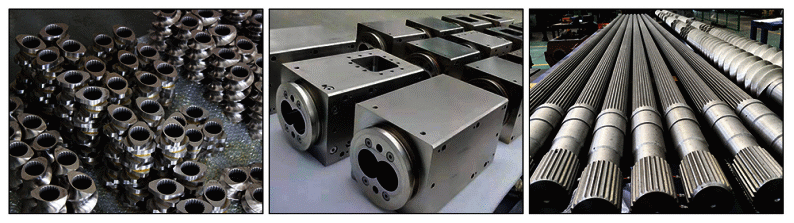

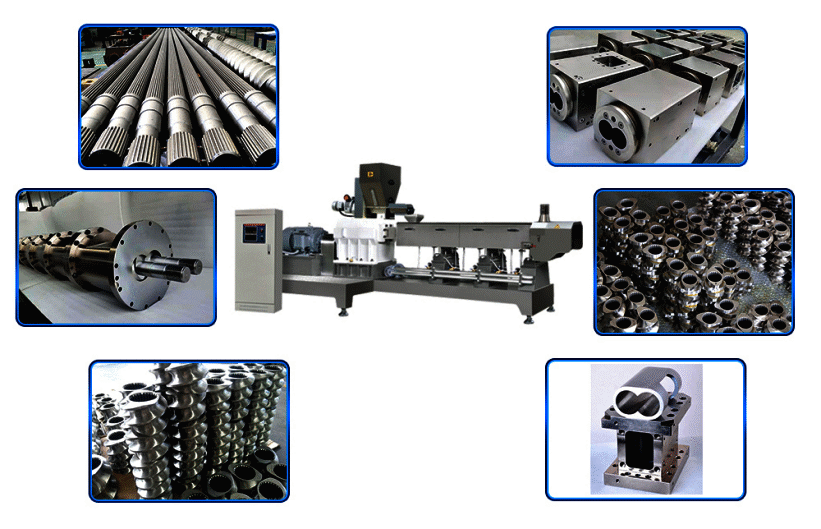

EQUIPMENT MATERIAL OF HIGH CAPACITY BUGLE SNACK FOOD MAKING MACHINE FOOD BUGLES CHIPS MACHINERY PRODUCTION LINE:

1. All Fried bugle chips production line are made of food grade stainless steel

2. Screw: Alloy steel (38CrMoAl)

3. HRC hardness is around 60 --- 62, with good self-cleaning ability, no need to unload or clean the barrel and screw when baking or changing materials.

4. The extrusion cylinder is made of carbon steel, made of 45 steel, stainless steel coating.

5. The gearbox has an automatic lubrication function, which can extend the life of the gear.

6. The cutter is fixed on the die head base and rotates through the V-belt drive.

THE ADVANTAGES OF HIGH CAPACITY BUGLE SNACK FOOD MAKING MACHINE FOOD BUGLES CHIPS MACHINERY PRODUCTION LINE:

The Advantage Of Industrial Fried Bugle Chips Production Line | |

| (1) | Variable frequency speed regulation and high degree of automation. |

| (2) | Runs smoothly and has a long service life. |

| (3) | Materials are made of alloy steel and special craftsmanship. |

| (4) | A long-lasting use time, high pressure and longer screw life. |

| (5) | Self-cleaning function, it can be cleaned without disassembly when stopped. |

| (6) | With automatic temperature control system, so the temperature control more intuitive and the parameters more precise. |

Which Market Of The Fried Bugle Chips Production Line Has Been Loyal Sold In 2021 ?

Customer Case Of Muti-Function Fried Bugle Chips Production Line With Discount Price In 2021 | |

1 | 100-150/H 2D 3D Potato Snack Pellet Food Processing Line Bugles Chips Making Machine For Sale Senegal Suppliers Factory |

2 | 300kg/h Fried 3D Pellet Bugles Chips Snack Food Processing Making Machine For Sale Nigeria |

3 | 100-150Kg/H Double Screw Fried Puff Ball Crispy Bugle Chip Core Filled Maize Flour Small Corn Puff Food Snack Extruder Machine For Sale Burkina Faso Manufacturing Processing |

4 | 150Kg/H Automatic Corn Fried Bugles Chips Production Line For Sale Botswana Agent |

5 | 100-150kg/h Fried Snacks Chips Food Extruder Machine For Sale Philippines Customer Factory Plant |

6 | 800kg/h Automatic Fried Bugles Chips Machine Fry Machine For Sale Pakistan With Discount Price For Sale |

7 | 200-250 Kg/Hautomatic Fried Pellet Machine Corn Snacks Extruder Bugles Chips Snacks Machine Processing Machine Line For Sale Mozambique |

Transaction Case Of The Commercial Bugles Chips Processing Line With High Quality Manufacturer In 2021 | |

1 | 200-250kg/h Commercial Fried Bugles Chips Machine Corn Chips Making Machine Manufacturers Food Production Line For Sale Austrian Agent |

2 | Ly65 100-150kg/h Capacity Small Frying Crispy 3D Corn Bugles Pellets Fried Chips Snacks Food Machine For Sale To Moldova Factory Plant |

3 | 100-150kg/h Bugles Making Extruder Machine Processing Equipment For Sale Ukraine |

4 | Ly-65 Frying Snacks Processing Machine Crispy Bugle Chips Snack Food Processing Machine For Sale Singapore Factory Plant |

5 | 400kg/h Fried Flour Snacks Bugle Chips Machinery Extruder Production Line For Sale Puerto Rico |

Transaction Case Of The Commercial Bugles Chips Processing Line With High Quality Manufacturer In 2021 | |

1 | 200-250kg/h Commercial Fried Bugles Chips Machine Corn Chips Making Machine Manufacturers Food Production Line For Sale Austrian Agent |

2 | Ly65 100-150kg/h Capacity Small Frying Crispy 3D Corn Bugles Pellets Fried Chips Snacks Food Machine For Sale To Moldova Factory Plant |

3 | 100-150kg/h Bugles Making Extruder Machine Processing Equipment For Sale Ukraine |

4 | Ly-65 Frying Snacks Processing Machine Crispy Bugle Chips Snack Food Processing Machine For Sale Singapore Factory Plant |

5 | 400kg/h Fried Flour Snacks Bugle Chips Machinery Extruder Production Line For Sale Puerto Rico |

High Quality Trader Customer Case Of The Industrial Fried Salad Chips Food Equipment Processing Line Price In 2021 | |

1 | 100kg/h Puffed Snacks Flour Fried Salad Chips Food Maker Machine Production Line For Sale Bolivia Agent |

2 | 800kg/H Industrial Fried Bugles Triangle Chips Food Processing Equipment Cost Price For Sale Dominica |

3 | 300kg/h Fried Sticks Food Maker Machine Production Line In Senegal Manufacturers |

4 | 100-150Kg/H Fried Snacks Making Machine Crispy Chips Making Machine Bugles Chips Processing Machinery Price In Nigeria |

5 | 200-250kg/h Double Screw Fried Puff Ball Crispy Bugle Chip Extruder Machine Factory For Sale Cote d'Ivoire |

6 | LY-65 Testing Machine For Bugles Food Making Machine Snack Machine Cost For Sale Cameroon |

7 | LY-70 Cone Shape Fried Corn Bugles Chips Machine Snacks Food Production Line For Sale South Africa Pet Food Suppliers |

OUR SERVICE & TURNKEY SOLUTION

1. ) Consultation service before, during, and after sales;

2. ) Project planning and design service;

3. ) Debugging of equipment until everything is functional;

4. ) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5. ) Training of equipment maintenance and operating personally;

6. ) New production techniques and formulas;

7. ) Provide 1 year complete warranty and life-time maintenance service.

COMPANY INTRODUCTION

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, puffed and fried bugle snack machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, cornflakes prodcution line, instant noodle machinery, pasta machinery, etc. food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions and better after-sales service.

We have sold our fried bugle snack plant to below countries:

Asia {Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan}

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine }

North & South America { Canada, Brazil, Bolivia }

Oceania { New Zealand }

ENGINEERS AVAILABLE TO SERVICE MACHINERY OVERSEAS

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free debugging of equipment until everything is functional;

4. Free management of equipments' long distance shipping;

5. Free training of equipment maintenance and operating personally;

6. Free new production techniques and formulas;

7. Provide 1 year complete warranty and lifetime maintenance service.

OUR HONOR

Loyal brand was famous well-known at global and domenstic market, and it is sold to more than 50 countries and regions, with ISO system, SGS certificate, 10 CE certificates, and 25 patents on Technology Patent, since then, we keep forward on the quality control, new technology developing and the better customer service.