Which is the best pasta maker in India?

Pasta, also known as spaghetti, is the most popular pasta in Western dinners. There are many types of spaghetti, each with its own name, and the length varies. The hollow type is called macaroni.

As the legal raw material for pasta, duran wheat is the hardest wheat variety with the characteristics of high density, high protein, and high gluten. The whole pasta made from it is yellow, resistant to cooking, and has a good taste.

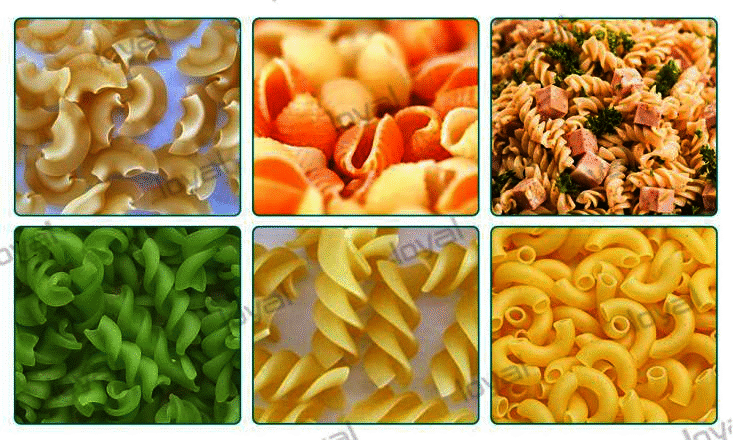

The shape of the pasta varies according to the type. In addition to the ordinary straight powder. There are also screw-shaped, elbow-shaped, butterfly-shaped, hollow-shaped, and shell-shaped. There are thousands of types.

Which is the best pasta maker in India?

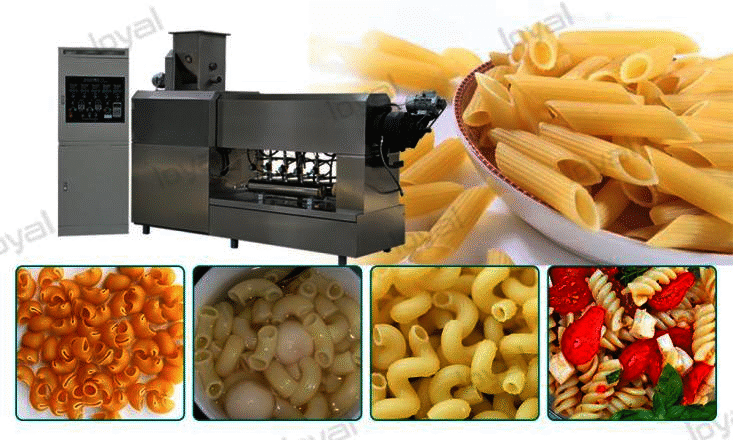

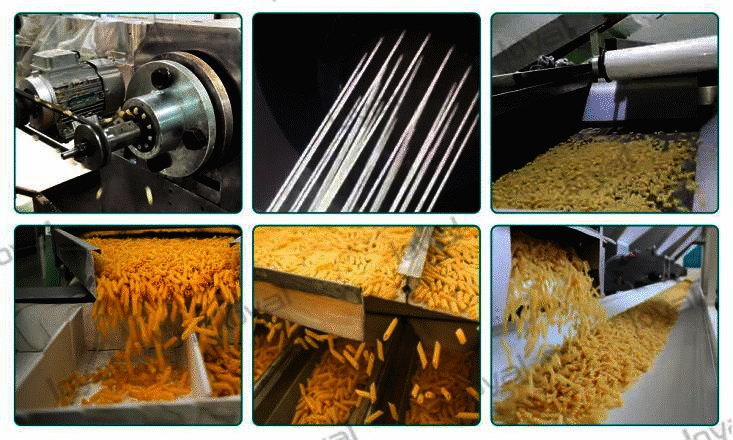

The full-automatic macaroni production line uses durum wheat flour as the main raw material. To form macaroni foods of different shapes through extrusion, maturation, and mold forming. This extruder can be used to produce macaroni in the same shape. Our company adopts continuous vacuum extrusion technology. Which is highly automated. The product is crystal clear and transparent without bubbles. And has a chewy texture. It is the first equipment for macaroni manufacturers.

Process Flow Of Macaroni Making Machine

① Mix noodles Automatically mix the raw materials with a certain amount of water and mix them evenly. The amount of water and the mixing time can be set in advance. And the equipment is easy to operate and clean;

②Automatic feeding Through screw conveying, the dough can fall into the extrusion process evenly and stably. And the conveying speed can be adjusted;

③Extrusion molding The dough is formed by extrusion, and the die diameter and shape are adjustable;

④Pre-cooling The surface of the pasta is cooled quickly by a fan, which is easy to cut;

⑤Cut off Cut the pasta, the length is adjustable;

⑥Pre-dryer The temperature and humidity of the pre-dryer are automatically controlled to save energy consumption.

⑦Automatic drying and cooling In order to achieve a uniform drying effect. The drying tunnel is automatically adjusted according to the drying curve. The dried pasta is cooled to the greenhouse for packaging. So as to ensure the quality of the product and facilitate storage;

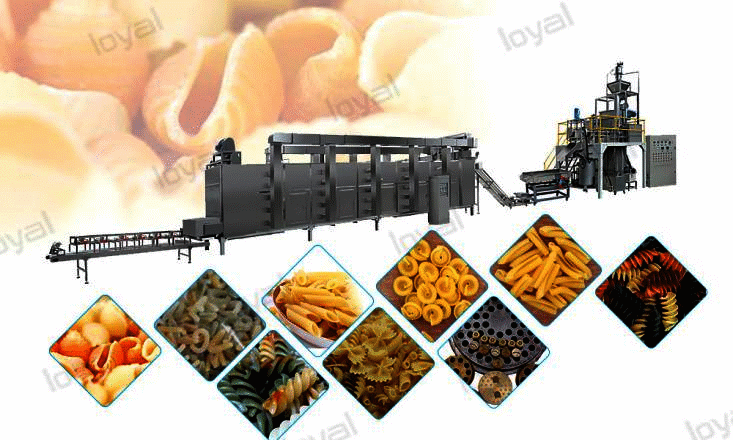

The main features of our pasta production line are as follows:

| 1. specifications | The product specifications are diversified to meet the various needs of different customers. Ranging from 150 kg to 1,000 kg of raw grain per hour produced by a single machine; |

| 2. worker | The macaroni pasta making machine is basically fully sealed. And only a few people are required to patrol and operate. Which greatly reduces labor costs; |

| 3. Operate | The macaroni pasta making machine runs smoothly, the performance is stable and reliable, and the failure rate is low; |

| 4. structure | The structure design of macaroni production line is scientific and reasonable. And all spare parts and accessories adopt domestic or international famous brand products. At the same time, automatic detection sensors are installed in the important process links of the macaroni production line . Which can monitor the working conditions in real time, so that the product quality can be traced; |

| 5. Material | SUS304 stainless steel is used for the inside and outsourcing of the whole machine. The inner wall of the extruder sleeve is made of SUS304 stainless steel. And the extrusion screw is made of alloy steel. All pipes are quick-connected and easy to disassemble and clean; |

| 6. High degree of automation | This production line has gradually adopted PLC and touch screen to replace traditional buttons. Temperature control meters, frequency meters, potentiometers and other electrical devices. And adopts man-machine interface equipped with Ethernet switches to issue commands to realize information exchange and control . |

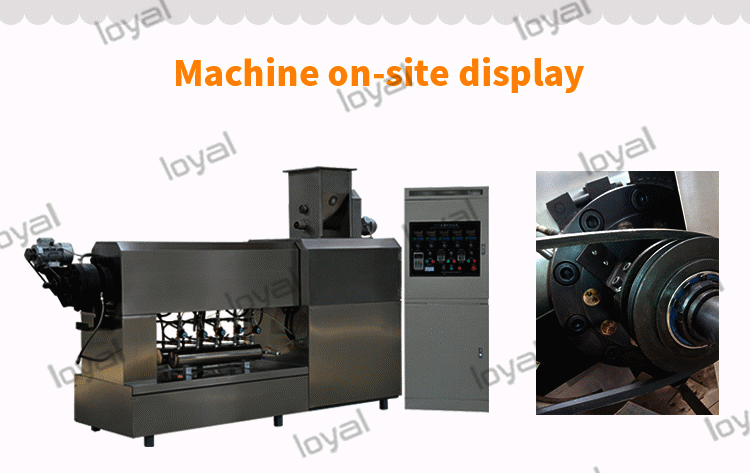

The Advantage Of Our Pasta Production Line Macaroni Pasta Making Machine

The macaroni pasta making machine adopts an integrated closed continuous production design. The raw materials are automatically input to the pasta and cut off. There is no need for manual operation in each link of production, which reduces the secondary pollution of the product and ensures the safety and sanitation of the food produced.

This series of production lines has high degree of automation, smooth process, convenient operation, less labor, and high qualified rate of output products, which greatly reduces production costs and is widely welcomed by users.