Isolated Soya Protein TSP Soya TVP Extrusion Machine Meat Processing Equipment Line Making Machine

Tvp extrusion machine adopts low-temperature soyabean powder as main material to produce new foods which looks like muscle and has the sense of mastication. This kind of food has highly nutrition and can be widely applied in many in industries: ham, can, fast -food, instant-cool food etc. Tvp extrusion machine is a new kind of inflating processing line, which is produced and developed according to rich experiences and the requirement of food market. This kind of machine adopts low-temperature soyabean powder as main material to produce new foods which looks like muscle and has the sense of mastication. This kind of food has highly nutrition and can be widely applied in many in industries: ham, can, fast -food, instant-cool food etc. This line is include mixer, double screw extruder, the compound shaping machine, fryer, the flavoring machine. It can produce the snack food by automatically.

Isolated Soya Protein TSP Soya TVP Extrusion Machine Meat Processing Equipment Line Making Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 10-25 working days. |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Isolated Soya Protein TSP Soya TVP Extrusion Machine Meat Processing Equipment Line Making Machine Detail Introduction :

Tvp extrusion machine is a new kind of inflating processing line, which is produced and developed according to rich experiences and the requirement of food market. This kind of machine adopts low-temperature soyabean powder as main material to produce new foods which looks like muscle and has the sense of mastication. This kind of food has highly nutrition and can be widely applied in many in industries: ham, can, fast -food, instant-cool food etc. This line is include mixer, double screw extruder, the compound shaping machine, fryer, the flavoring machine. It can produce the snack food by automatically.

Tvp extrusion machine can produce different protein content products by changing formulations. You can get different structure and different shapes protein products, such as soya nuggets, soya chunks, soya mince,hmma high moisture soya protein, etc.

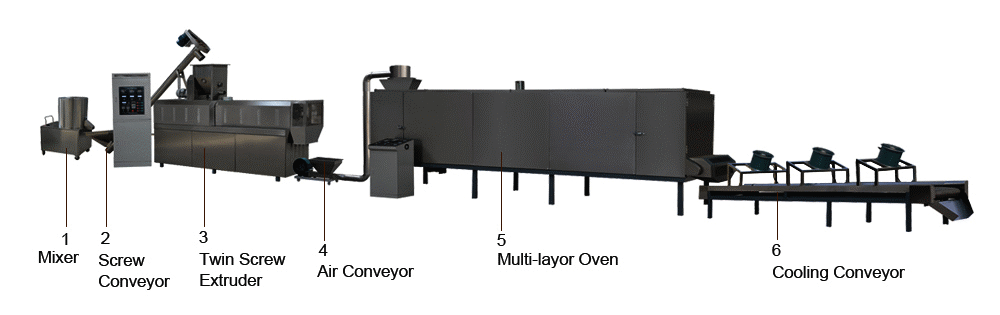

Flow Chart Of Tvp Extrusion Machine Line:

Mixer-Screw Conveyor-Twin Screw Extruder- Air Conveyor- Oven - Cooling machine

Youtobe:

Technical Parameter Of Tvp Extrusion Machine :

| Technical Parameter of Tvp Extrusion mMachine | ||||

| Model | InstalledPower(KW) | Power Consumption(KW) | Capacity(kg/h) | Dimension(m) |

| LY-1 Soya Protein food processing line | 74 | 52 | 100-150 | 17*1.2*2.2 |

| LY-2 Soya Protein food processing line | 95 | 70 | 200-300 | 20*1.5*2.2 |

| LY-3 Soya Protein food processing line | 139 | 102 | 300-500 | 28*3.5*4.3 |

TVP Extrusion Machine produce a kind of vegetarianism with meat like flavor and texture taste, also known as hmma high moisture soya protein.

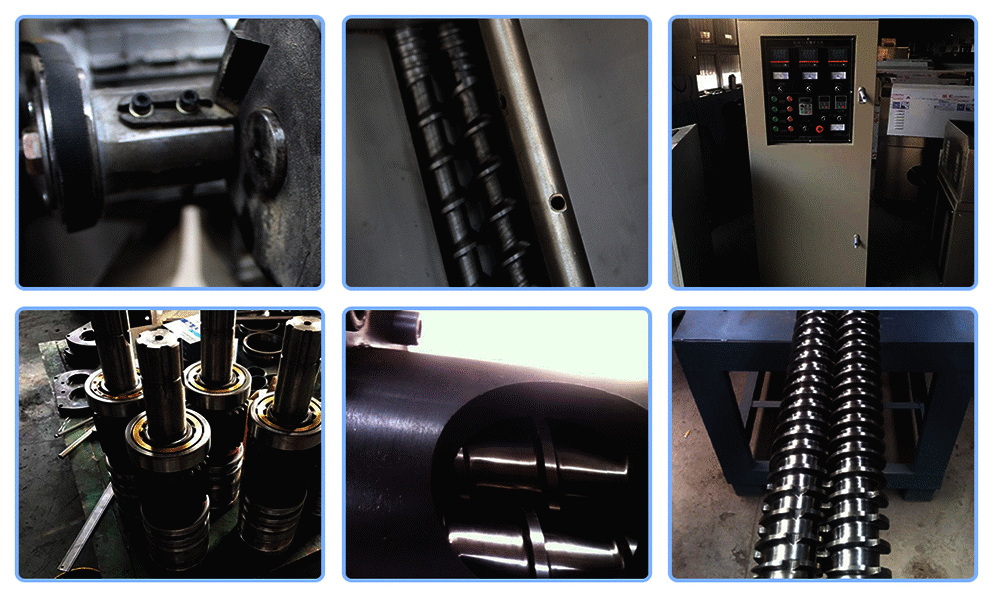

The production line has following features: many models, flexible equipment configuration, wide range of raw materials, a wide variety of final products, and simple operation. By changing the cutters, it can produce different kinds of protein shapes to meet customer requirements. This kind of product is popular with vegetarians.

Applications Of TVP Extrusion Machine

1. Dry Textured soya protein Pellets, Crumbs, Minced, Flakes, Chunks, Chips ,Schnitzel, Nuggets.

2. High moisture wet protein Soya,pea, Pea-sunflower

The TVP Extrusion Machine is a new type of puffing equipment developed by our company based on years of experience in order to meet the needs of the commodity market. This equipment uses low-temperature soybean meal or peanut meal as raw materials to produce lean and chewy new foods, which can be widely used in ham, sausage, canned food, fast food, quick-frozen food and other industries.

This TVP Extrusion Machine can produce many kind shapes soy proteins by changing the mould:

Why choose us?

| Why Choose Our Soya Meat Making Machine | |

| 1 | We pay more attention on each detials of the equipment. |

| 2 | We are a important leading enterprise in Shandong, providing employment opportunities for local residents, helping the poor and helping farmers, and participating in charitable activities. |

| 3 | One year warranty for the machines. |

| 4 | Overseas installation and train the first-line operators. |

| 5 | For any questions, professional technicians will solve for you timely. |

| 6 | Training workers for the production. |

FAQ:

Q:How much does the soy protein production line cover?

A:Usually is 26-30M

Q:How many workers does the protein machine need

A: 3-4 workers

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 10 days if the goods are in stock. or it is 30-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

30% is paid by T/T as the down payment, 70% is paid by T/T orL/C before shipment

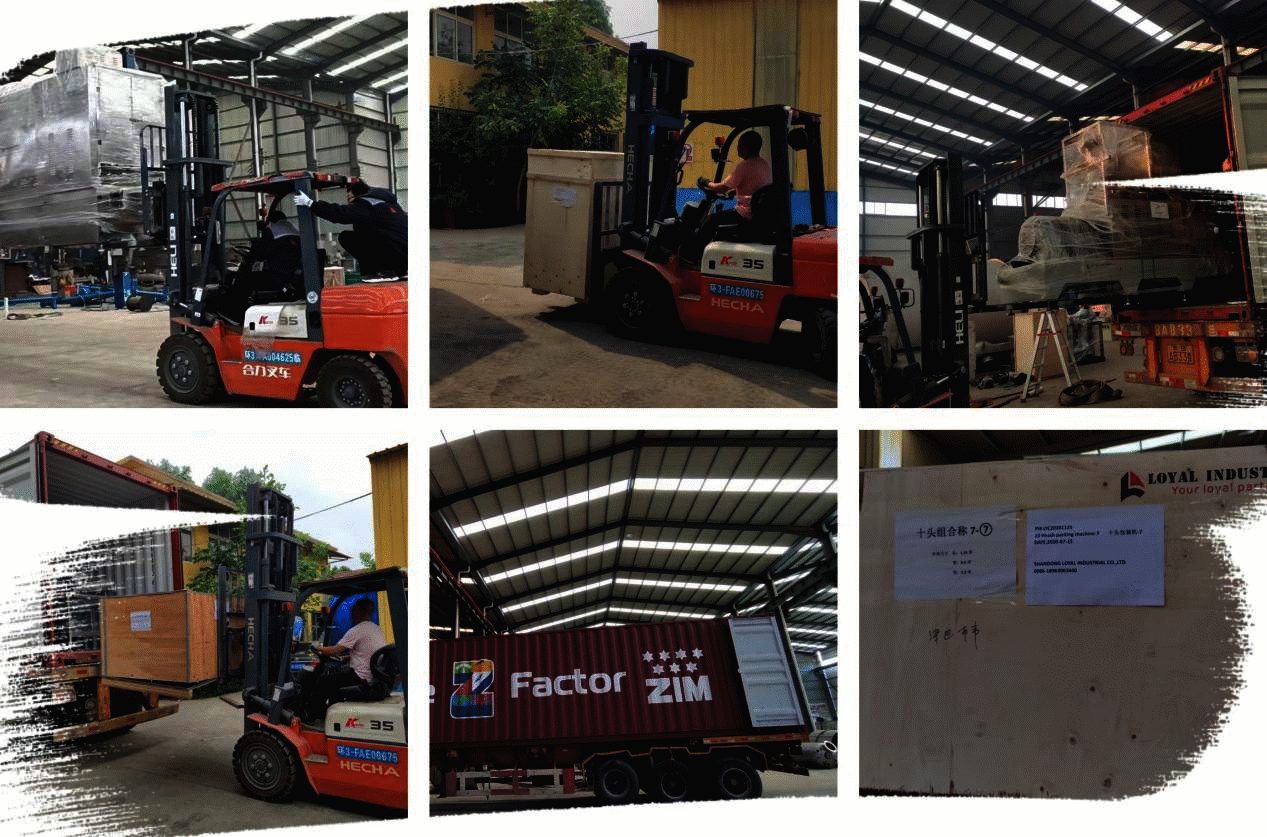

Packaging & Shipping:

Package: wooden cases for sea transportation

Delivery time: 30 working days after receiving the deposit

Installation : engineers available for installation and training overseas

Guarantee : 12 months after it is sent out

Our factory famous well-known at global and domenstic market, and it is sold to more than 50 countries and regions, with ISO system, SGS certificate,10 CE certificates, and 25 patents on Technology Patent, since then,we keep forward on the quality control, new technology developing and the better customer service. Our leading products are food extruders, industrial microwave system, biscuit production line, instant noodles production line, puffed &fried snack food, breakfast cereal corn flakes, fortified rice production line, textured soy protein (TSP) food, pet food &fish feed prodcution line,packing machine.

2021 Customer Order Soya Mest Making Machine List:

| Dealed Customer Customers Who Have Not Worked In The Soya Meats Industry Before In 2021 | |

| 1 | China 300t/Year Soya Meats Manufacturing Technology |

| 2 | 1t/h Soya Meats Equipment For Sale In Indian |

| 3 | 1t/h Soya Meats Equipment For Sale In Bolivia |

| 4 | Senegal 1t/h Soya Meats Machine |

| 5 | 1t/h Soya Meats Machine For Sale In Côte d'Ivoire |

| Customers Who Understand Soya Meats Processing Technology | |

| 1 | 1t/h Soya Meat Machine Sold In Russia |

| 2 | 1t/h Soya Meat Brands For Sale In Uzbekistan |

| 3 | 1000kg/h Soya Meat Equipment For Sale In Senegal |

| 4 | Mozambique 1t/h Soya Meats Hot Machine |

| 5 | Bangladesh 2t/h Soya Meats Hot Machine |

| Dealed Customer Have Plant Of Soya Meats Production Line In 2021 | |

| 1 | 1t/h Soya Meat Brands Machine |

| 2 | Uzbekistan 1t/h Soya Meats Manufacturing Equipment |

| 3 | Usa 1t/h Soya Meats Manufacturing Equipment |

| 4 | 800kg/h Soya Meats Manufacturing Equipment For Sale In Nigeria |

| 5 | Algerian Soya Meats Hot Machine |

| Dealed Customers Who Low-Price Purchase Soya Meats Production Line In 2021 | |

| 1 | Sudan 200kg/h Soya Meats Production Line |

| 2 | Moldova Small 200kg/h Soya Meats Production Line |

| 3 | 200kg/h Soya Meats Production Line Sold In Ukraine |

| 4 | Nigeria 150kg/h Soya Meats Hot Machine |

| 5 | Austria Sells Industrial Soya Meat Production Line |