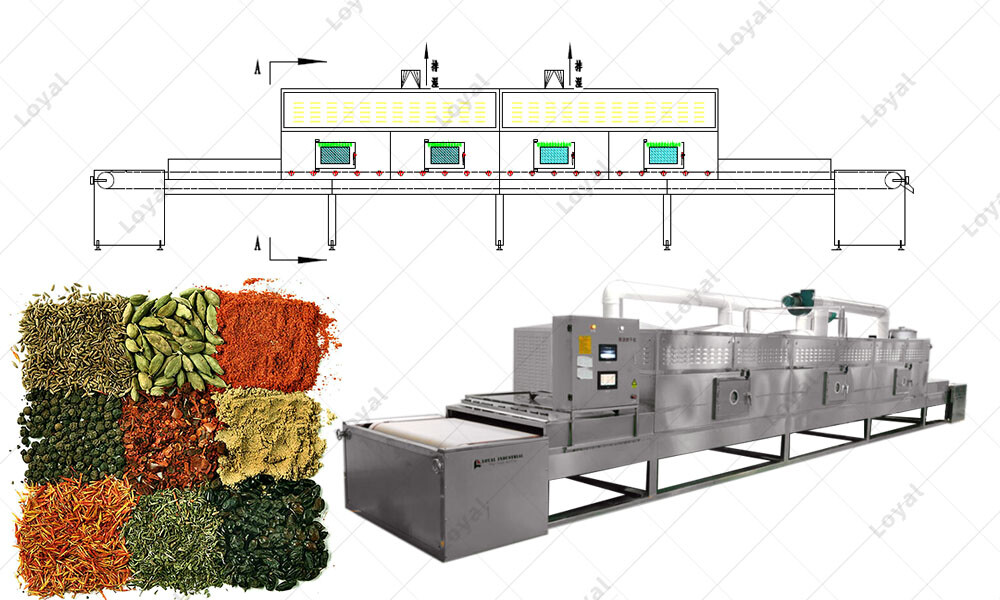

Seasoning Drying Microwave Oven

Description Of Seasoning Drying Oven

A seasoning drying oven is a specialized piece of equipment designed to remove moisture from various types of seasonings or spices. The oven operates by circulating hot air over the seasoning, which helps to evaporate any moisture that may be present. The drying process helps to increase the shelf life of the seasoning by reducing the moisture content, preventing bacterial growth, and ensuring that the product remains fresh.The oven typically consists of a chamber or compartment where the seasoning is placed on trays or racks. The oven is equipped with heating elements and a fan to circulate the hot air evenly throughout the chamber. The temperature and humidity levels can be controlled using a digital controller, allowing for precise drying conditions to be maintained.Some seasoning drying ovens may also include additional features such as air filtration systems to remove dust and other contaminants from the air, as well as safety features such as automatic shut-off switches and alarms to prevent overheating or other malfunctions.

Overall, a seasoning drying oven is an essential tool for manufacturers of seasonings and spices, as it helps to ensure the quality and longevity of their products by effectively removing moisture and preserving flavor.

How To Dry The Seasoning

While it is possible to dry herbs and seasonings in a microwave oven, it's important to do it carefully to prevent burning or overheating the herbs. Here are some steps you can follow:

1.Rinse the seasonings and pat them dry with a paper towel.

2.Remove any stems or leaves that are damaged or discolored.

3.Spread the seasonings out in a single layer on a microwave-safe plate or paper towel.

4.Microwave the seasonings on high power for 30 seconds to 1 minute. Check the herbs every 15 seconds to make sure they're not burning.

5.Repeat the process until the seasonings are dry and crumbly. This can take anywhere from 1 to 5 minutes, depending on the type of herb and the wattage of your microwave.

6.Let the seasonings cool completely before storing them in an airtight container.

Features Of Microwave Drying

Uniform Heating | As microwave acts on water molecules, so the part with high water content absorbs more microwave power than the part with lower water content. This is the characteristic of selective heating, using this feature can achieve uniform heating and uniform drying. |

High Efficiency And Energy Saving | Microwave is directly on the role of materials, so there is no additional heat loss, the air in the furnace and the corresponding container will not heat, so the thermal efficiency is very high, the production environment is also significantly improved, compared with far infrared heating can save 30% of electricity. |

High Efficiency Short Time | Because microwave heating does not require the process of heat conduction, so the microwave penetrates the object from different directions into the object inside, from inside to outside so that the material in a very short time to achieve uniform drying, effectively shortening the drying time. |

Easy To Control | Compared with conventional methods, microwave operation is easy; microwave power adjustable, adjustable transmission speed. |

Advantages Of Seasoning Drying Oven

Efficient Drying | A seasoning drying oven provides a controlled and efficient drying environment that reduces drying time and increases productivity. |

Consistency | The oven provides a consistent and controlled environment that ensures that the wood products are dried uniformly, reducing the risk of warping or cracking. |

Improved Quality | The drying process removes excess moisture from the wood, reducing the risk of decay, mold, and other issues that can affect the quality of the wood. |

Reduced Waste | The drying process reduces the moisture content of the wood, resulting in less weight and lower transportation costs. |

Energy Efficient | Many seasoning drying ovens are designed to be energy efficient, reducing the cost of operation and making them an environmentally friendly choice. |

Increased Capacity | By using a seasoning drying oven, manufacturers can increase their production capacity, as they can dry and cure large quantities of wood products in a shorter time frame. |

Better Control | The oven allows for better control of the drying process, allowing manufacturers to adjust the temperature and humidity levels to ensure optimal drying conditions for different types of wood products. |

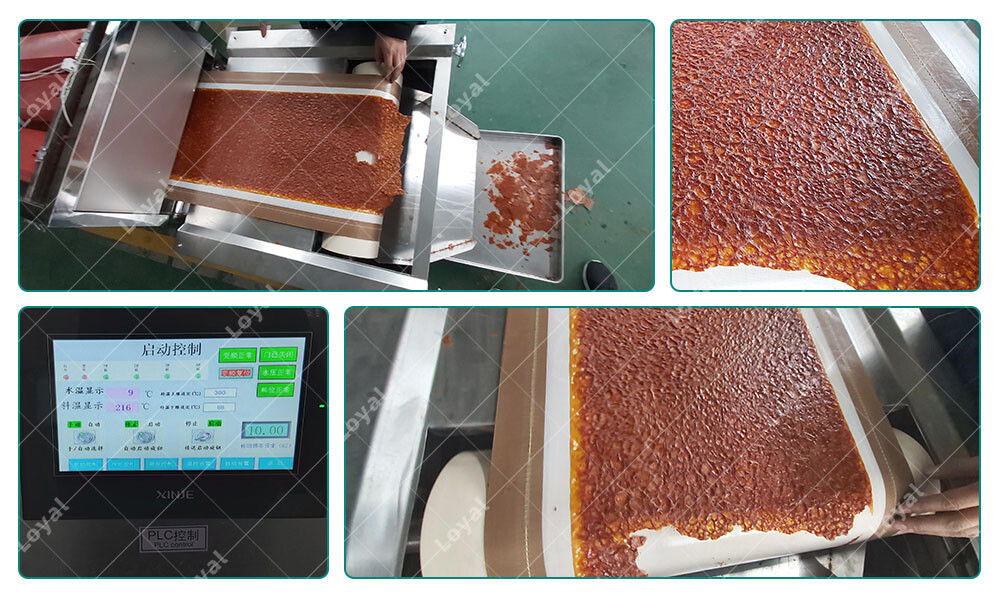

Seasoning Product Display

A seasoning product is a type of food product that is used to enhance the flavor of dishes. Seasoning products come in various forms, including spices, herbs, blends, marinades, rubs, and sauces. They can be added to food during the cooking process or used as a finishing touch to add extra flavor.

Common seasoning products include salt, pepper, garlic, onion powder, paprika, chili powder, cumin, oregano, thyme, basil, rosemary, and parsley. Many seasoning products are also made from a combination of different herbs and spices, creating unique and complex flavor profiles.

Seasoning products are popular in many cuisines and can be used in a variety of dishes, including meats, vegetables, soups, stews, and sauces. They are also often used to create homemade marinades and rubs for grilling and roasting.