Processing process of soy meat production line

Soy meat is a prevalent food with high protein content, rich fiber texture, tasty meat, no cholesterol, and animal fat, which is suitable for both young and old. It is widely used in the meat industry, quick-frozen food production, fast food production, and various vegetarian snacks. It is healthy and safe food.

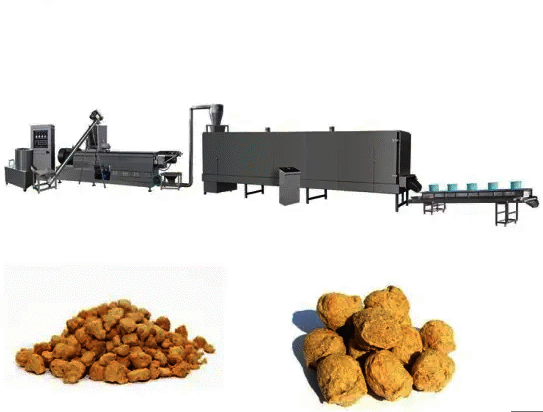

The main production and processing of soy meat are the Soya Meat Making Machine, which is an advanced and efficient equipment specially designed for making soy meat. This production line uses low-temperature soybean meal, peanut meal, and wheat gluten separated soybean as the main raw materials, producing new food products with certain strength and toughness of tissue protein and fibrous protein.

Soybean meat production line consists of mixer, screw conveyor, twin-screw extruder, airflow conveyor, dryer, elevator, seasoning roller oil sprayer, cooler, packaging machine. The working conditions of the main equipment are as follows:

1, mixer: mixer and material contact part using stainless steel materials, the discharge hole using a new handle opening design. It makes the water-added raw materials and liquid additives fully mixed, has good sealing properties, and makes the materials evenly mixed.

2、Conveyor: The mixed materials are conveyed to the feeder of the extruder in stainless steel drum without any leakage, dust, and pollution, and the feeding volume and speed are uniform and stable.

3、Extruder: Twin-screw extruder consists of feeding, extrusion, cutting, heating, transmission, and control system. The screw is made of alloy steel, forced lubrication system, automatic temperature control system, automatic speed control system, using the extruder, starch is modified by heating and pressing.

4、Cutter: It is made of SUS, it has two motors, one is to control the transfer of products, and the other is to control the cutting speed, it also has two inverters.

5、Lifter: The lifter conveys food from low to high according to the process.

6、Crusher: The crusher is to beat the flakes into different shapes. It has different capacities and is made of SUS304 food grade.

7、Packing Machine: The deformed soy protein is packed in plastic bags of the required weight.

The Soya Meat Making Machine is highly automated, and the process is relatively simple. A whole production line comes down to complete the production of soy meat. By changing different molds, it can also produce other types of food, such as vegetarian steak, vegetarian chicken wings, vegetarian meat, vegetarian chicken, bean shrimp, bean sausage, etc. It greatly saves labor time, improves work efficiency, and has many advantages.

Advantages of Soya Meat Making Machine:

1、Using special advanced materials and technology, the machine is resistant to wear and tear and has a long service life.

2、Can process various materials, frequency conversion speed control, stable molding, superior performance.

3、New direct transmission system, more power, greatly reduce the energy consumption.

4、PLC touch screen system, simple and convenient operation, greatly saves manpower.

5、The production line is reasonably designed. The screws are made of alloy steel, with a building block system structure and self-cleaning function.

The above is the processing process of the soy meat production line. Compared with other soy meat production methods, the processing line has more advantages, the production of food is also better quality. Choose it for making soy meat. That's right.