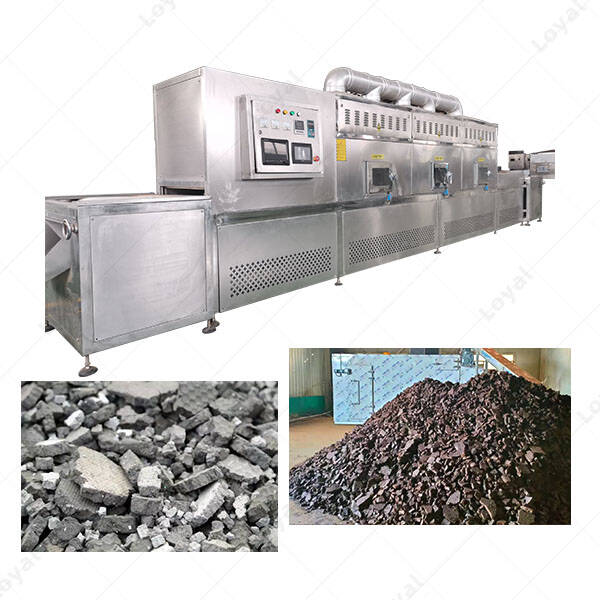

PLC Control Sludge Automatic Microwave Drying Machine

As one professional automatic microwave kaolin sludge dryer manufacturer,we can offer small, medium and large PLC control sludge automatic microwave drying machine for sale. The sludge microwave dryer equipment has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements.

PLC Control Sludge Automatic Microwave Drying Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Sludge Automatic Microwave Drying Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sales Team | Microwave Drying Sterilizing Machine Process Technology Engineer |

PLC Control Sludge Automatic Microwave Drying Machine Detail Introduction :

As one professional automatic microwave kaolin sludge dryer manufacturer,we can offer small, medium and large PLC control sludge automatic microwave drying machine for sale. The sludge microwave dryer equipment has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements.

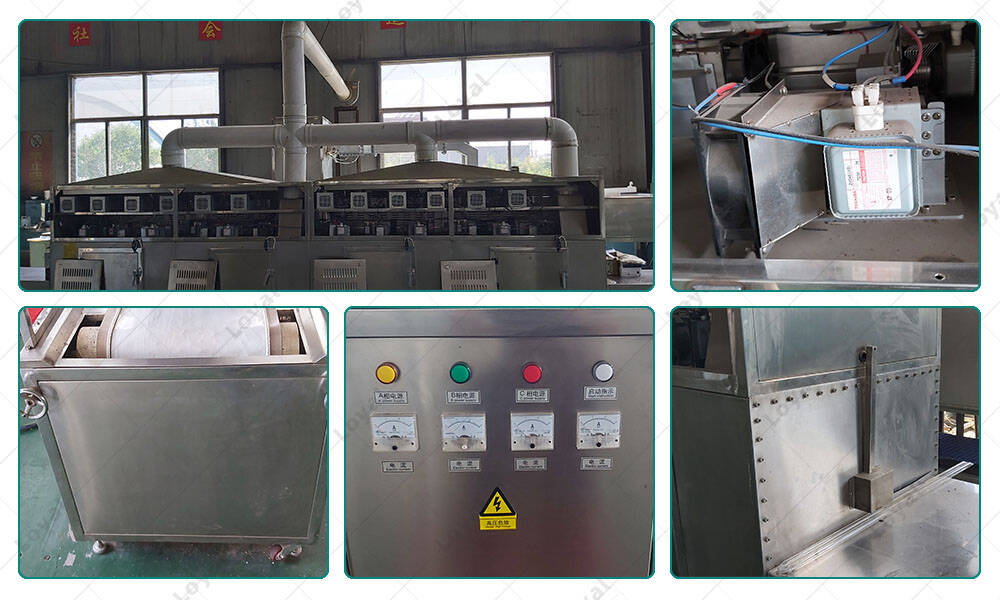

The microwave drying equipment for sludge includes: a screw conveyor is connected to the inlet of the sludge molding machine, a conveyor belt is arranged in the sludge microwave drying machine, and the outlet of the sludge molding machine is communicated with the interior of the sludge microwave drying machine. The microwave generating device is connected with the sludge microwave dryer through a waveguide, and the exhaust fan inlet of the dust collecting unit is connected with the cyclone dust collector through a pipeline. The sludge is heated and dried by microwave, and the hot air and dust in the drying process are removed by cyclone dust collector and spray dust collector. Low energy consumption, high sludge drying efficiency, good operating environment, effectively reducing sludge moisture content, saving floor space and avoiding secondary pollution.

WHAT ARE FEATURES OF PLC CONTROL SLUDGE AUTOMATIC MICROWAVE DRYING MACHINE?

Features Of PLC Control Sludge Automatic Microwave Drying Machine | |

| 1 | Short drying time and high efficiency. |

| 2 | The drying temperature is low and uniform, and the composition of the raw material can be maintained. |

| 3 | Selective heating, uniform and thorough. Because water molecules absorb microwaves well, the part with high water content absorbs more microwave power than the part with lower water content. This is the feature of selective heating, which can be used to achieve uniform heating and uniform drying. |

| 4 | Energy saving and high efficiency. The microwave directly acts on the material, so there is no additional heat loss. Compared with the energy saving of more than 30%, no waste is generated in the whole drying process. |

| 5 | The sludge microwave dryer equipment adopts tunnel structure, PLC automatic control, automatic temperature control system, video monitoring system, conveyor belt automatic deviation correction system, transmission frequency conversion speed regulation system, etc., real-time monitoring, - - key setting, automatic system, operation Simple and low labor intensity; the equipment is mainly made of stainless steel plate, which has strong thermal insulation performance and corrosion resistance, saves energy consumption, good working environment and long service life of the equipment. |

TECHNICAL PARAMETER OF PLC CONTROL SLUDGE AUTOMATIC MICROWAVE DRYING MACHINE

Technical Parameter Of Plc Control Sludge Automatic Microwave Drying Machine | |||||

| No | Model | Power(Kw) | Dehydration Capacity (Kg/h) | Sterilization Capacity (Kg/h) | Size (m) |

| 1 | LY-12KWSP | 12 | 12 | 120-150 | 7×0.84×1.75 |

| 2 | LY-20KWSP | 20 | 20 | 192-240 | 9.4×0.84×1.75 |

| 3 | LY-30KWSP | 30 | 30 | 300-375 | 11.7×0.84×1.75 |

| 4 | LY-40KWSP | 40 | 40 | 396-495 | 10.52×1.06×1.75 |

| 5 | LY-50KWSP | 50 | 50 | 504-630 | 11.7×1.06×1.75 |

| 6 | LY-60KWSP | 60 | 60 | 600-750 | 12.86×1.06×1.75 |

| 7 | LY-70KWSP | 70 | 70 | 696-870 | 14.03×1.06×1.75 |

| 8 | LY-80KWSP | 80 | 80 | 804-1000 | 14.86×1.2×1.75 |

| 9 | LY-100KWSP | 100 | 100 | 1000-1250 | 15.2×1.2×1.75 |

| 10 | LY-150KWSP | 150 | 150 | 1500-1875 | 21.05×1.2×1.75 |

WORKING PRINCIPLE OF PLC CONTROL SLUDGE AUTOMATIC MICROWAVE DRYING MACHINE

Sludge microwave dryer equipment is a new technology using microwave drying material at low temperature, vacuum and oxygen-barrier conditions, with a fast-drying, high efficiency, and energy-efficient features. Under negative pressure, microwave can dry the material quickly by reducing the boiling point of water.

Sludge microwave dryer equipment uses intermittent operation mode, with tray bearing material, artificial loading & unloading material, simple operation, accurate temperature control. Microwave Field Density can be adjusted automatically according to the drying degree of material. At the same time, Batch type microwave vacuum dryer can set various programs according to different variety of materials production processes, at the same time optimize production to achieve real intelligent control.

WHICH MARKET DID THE LOYALSMALL SCALE PLC CONTROL SLUDGE AUTOMATIC MICROWAVE DRYING MACHINE SOLD?

LOYAL's share of sludge microwave dryer equipment exported to international markets has steadily increased. According to the export goods trade data in 2021, Loyal's export market share in the international market is 86.5%, of which the sludge microwave dryer equipment export market share is 20.8%, the export market share in the Americas is 30.2%, and the export market share in Asia is 35.5%. If you are interested in a meat dryer, please contact us today, we offer you the most cost-effective turnkey solution.

Customer Have Formula Request Of Sludge Microwave Dryer Equipment | |

1 | China 300t/Year Industrial Automatic Microwave Sludge Dryer |

2 | 1T/H Sludge Microwave Dryer For Sale In Puerto Rico |

3 | 1T/H Sludge Microwave Dryer For Sale In Bolivia |

4 | 800Kg/H Automatic Microwave Sludge Dryer For Sale In Argentina |

5 | 2T/H Automatic Microwave Sludge Dryer For Sale In Benin |

6 | 2T/H Plc Control Sludge Automatic Microwave Drying Machine For Sale In British Indian Ocean Territory |

7 | 2T/H PLC Control Sludge Automatic Microwave Drying Machine For Sale In Chile |

Cooperated Customer For Laboratory Machine Of Automatic Microwave Sludge Dryer | |

1 | Senegal 200Kg/H Industrial PLC Control Sludge Automatic Microwave Drying Machine |

2 | 100-200Kg/H PLC Control Sludge Automatic Microwave Drying Machine For Sale In Côte d'Ivoire |

3 | 300-400Kg/H Automatic Microwave Sludge Dryer For Sale In Sold In Russia |

4 | 500KG/H Automatic Microwave Sludge Dryer For Sale In Sold In Denmark |

5 | 600KG/H Automatic Microwave Sludge Dryer For Sale In Dominica |

6 | 100-200Kg/H PLC Control Sludge Automatic Microwave Drying Machine For Sale In Egypt |

7 | 300-400Kg/H Automatic Microwave Sludge Dryer For Sale In Sold In Ethiopia |

Cooperated Customer Request Engineer Installation At 2021 | |

1 | 1T/H Factory Direct Sale Industrial Tunnel Microwave Waste Heat Sludge Drying Machine For Sale In Uzbekistan |

2 | 1000kg/h Industrial Automatic Microwave Sludge Dryer For Sale In Senegal |

3 | Mozambique 1T/H Automatic Microwave Sludge Dryer Machine |

4 | 1T/H Thai Automatic Microwave Sludge Drying Machine |

5 | Uzbekistan 1T/H Automatic Microwave Sludge Drying Machine |

6 | 2T/H Factory Direct Sale Industrial Tunnel Microwave Waste Heat Sludge Drying Machine For Sale In Germany |

7 | 2T/H Factory Direct Sale Industrial Tunnel Microwave Waste Heat Sludge Drying Machine For Sale In Guinea |

Cooperated Customer With Microwave Dryer Machine For Waste Water Sludge Technology At 2021 | |

1 | Nigeria 500Kg/H Microwave Dryer Machine For Waste Water Sludge |

2 | Austria Sells Microwave Dryer Machine For Waste Water Sludge 1000kg/h |

3 | Microwave Dryer Machine For Waste Water Sludge For Sale In Pakistan 1000kg/h |

4 | 1T/H Microwave Dryer Machine For Waste Water Sludge For Sale In India |

5 | 2T/H Microwave Dryer Machine For Waste Water Sludge For Sale In Israel |

6 | 2T/H Microwave Dryer Machine For Waste Water Sludge For Sale In Jamaica |

7 | 2T/H Microwave Dryer Machine For Waste Water Sludge For Sale In Morocco |