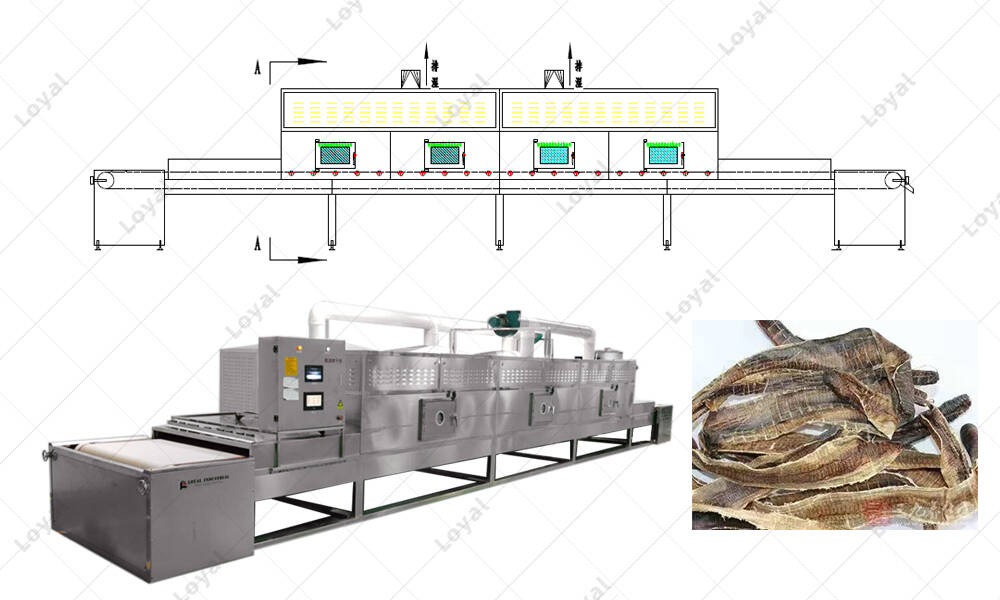

Microwave Insect Earthworm Tunnel Dehydrator Drying Machine

Microwave Insect Earthworm Tunnel Dehydrator Drying Machine equipment is an emerging drying technology. Since the heat directly comes from the inside of the drying material, the heat loss in the surrounding medium is very small. In addition, the microwave heating cavity itself does not absorb heat or microwaves,PLC Control Conveyor Mesh Belt Dryer Cocoa Beans Microwave Drying Machine is a high-frequency electromagnetic wave machine, which can instantly radiate through cocoa beans, pistachios and other nuts and grains, produce thermal effects and biological effects, and achieve the function of Industrial Microwave cocoa bean drying, as well as puffing, sterilization, drying, mildew prevention, etc. Features.

Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Insect Earthworm Dehydrator Drying Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Drying Sterilizing Machine |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sales Team | Microwave Drying Sterilizing Machine Process Technology Engineer |

Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Detail Introduction :

Microwave Insect Earthworm Tunnel Dehydrator Drying Machine

Drying Insect Earthworm with microwave drying equipment is an emerging drying technology. Since the heat directly comes from the inside of the drying material, the heat loss in the surrounding medium is very small. In addition, the microwave heating cavity itself does not absorb heat or microwaves, and it emits all the heat. Acting on the material, the thermal efficiency is high. Due to the advantages of fast drying speed and good quality, this technology has become the Insect Earthworm drying equipment for many Insect Earthworm farmers.

Introduction of Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer

Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer adopts clean energy, high degree of automation, no need for manpower, and no pollution of drying medium, energy saving and environmental protection.The industrial microwave systems adopts pulsed through-flow air supply technology to greatly improve drying uniformity. Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer has short processing time, easy control, good product quality, high expansion, color and freshness can be maintained, less loss of moisture and nutrients, low bacterial content, high processing efficiency, suitable for various Drying and milling of insects, such as Tenebrio molitor, barley worm, black soldier flies, and earthworms.

What is the Price of Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer?

| Industrial microwave systems | |||||

| Model | Ly | Order number | 3 | Rotating speed | 3 (r/min) |

| Article number | 5 | Brand | Loyal | Applicable materials | Variety available |

| Structure type | Multilayer belt | Application field | Food agriculture | Heat transfer area | 20 (m2) |

| Price | 20000usd | Power | 13 (kw) | Dimensions | 12×1.81×1.9(m) |

Market application of Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer

In addition to drying earthworms, what other products is this industrial microwave systems suitable for?

Microwave drying of Tenebrio molitor, drying of paper trays, drying of bread crumbs, drying of cat litter, drying of insects, drying of traditional Chinese medicine extract, microwave drying of black soldier flies, microwave drying of insulation board, drying of rope, yarn Line drying equipment, fly maggot microwave drying, glass fiber drying, epoxy resin curing, cotton drying.

How long does it take for insects to dry?

Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer provides instant heat drying without preheating. Microwave is different from the traditional heating method (from the outside to the inside), the microwave has penetrability, and the principle of the heating method is different (from the inside to the outside).

| Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer | ||||||

| Model | LY3-1.2-8 | LY3-1.2-10 | LY3-1.6-8 | LY3-1.6-10 | LY3-2-8 | LY3-2-8 |

| Number of units | 4×3 | 5×3 | 4×3 | 5×3 | 4×3 | 5×3 |

| Bandwidth (m) | 1.2 | 1.6 | 2 | |||

| Drying section length (m) | 8×3 | 10×3 | 8×3 | 10×3 | 8×3 | 10×3 |

| Paving thickness (mm) | 10-80 | |||||

| Operating temperature (℃) | 50-140 | |||||

| Steam pressure (mpa) | 0.2-0.8 | |||||

| Steam consumption (kg/h) | 360-600 | 420-720 | 450-840 | 480-960 | 480-960 | 630-1350 |

| Heat exchange area (m2) | 816 | 1020 | 1056 | 1320 | 1344 | 1680 |

| Drying strength kg water/h | 150-450 | 220-550 | 240-600 | 280-750 | 280-750 | 350-900 |

| Number of fans | 14 | 17 | 14 | 17 | 14 | 17 |

| Internal unit total power (kw) | 30.8 | 37.4 | 42 | 51 | 56 | 68 |

| Equipment total power (kw) | 35.3 | 41.9 | 46.5 | 55.5 | 60.5 | 72.5 |

| Dimensions (l×w×h) | 9.77×2.2×4.5 | 11.77×2.2×4.5 | 9.77×2.6*4.7 | 11.77×2.6×4.7 | 9.77×3.06×4.9 | 11.77×3.06×4.9 |

| Total weight kg | 4800×3 | 5780×3 | 5400×3 | 6550×3 | 6350×3 | 7800×3 |

| The amount of evaporated water shown in the figure depends on the drying temperature of the material, the thickness of the material and the residence time | ||||||

Microwave Insect Earthworm Tunnel Dehydrator Processing

1. Earthworm meal: The processing method of earthworm meal is simple. Fresh earthworms are air-dried or dried and then pulverized.

The protein content of dry earthworms is as high as 70%, which is comparable to imported fish meal and higher than domestic fish meal. The content of arginine is higher than that of fish meal. 2-3 times, rich in carotene, it is a high-protein health feed that animals need.

According to reports, earthworm meal is better than fish meal for raising chickens. Broiler chickens are added with 7.5% earthworm meal and 80% fish meal in the same diet.

In comparison, the weight gain increased by 13% in 5-6 days, and adding 4% earthworm meal to the laying hen feed increased the egg production by 20% compared with no addition.

2. Earthworm liquid:

There are more than 10 kinds of proteolytic enzymes and plasmin in the digestive tract of earthworms. These proteases have strong hydrolysis activity on proteins, and these enzymes are used to hydrolyze proteins and turn them into soluble small molecule active peptides and Amino acids, as additives, can be completely absorbed by farmed animals, exerting their anti-disease and growth-promoting effects.

Test results of aquaculture eel: After comparison of 5 groups of tests, the best formula is taught: fish meal 20%, earthworm liquid 11%, ESB yeast 9%, Cake meal 20%, energy feed 35%, MTS growth promoter 0.001%, additive 2%, adhesive 3%. Eel raising effect: weight gain 100.48%, bait coefficient 2.32, protein utilization rate 21.21%. Amino acid content in earthworm liquid High, rich in minerals and vitamins, is a new type of feed additive.

3. Antibacterial peptides:

The composition of protein amino acids in earthworms is similar to that of animals, which can be fully absorbed by animals, and glutamic acid accounts for 10% of its amino acids (the umami in MSG is glutamic acid).

The meat is tender and delicious, and the quality is improved. Studies have found that earthworms contain highly active phytase, which can significantly improve the digestion and absorption of mineral elements in animal feed.

It is also proved that earthworm body fluids contain broad-spectrum antibacterial substances-antibacterial peptides.

Using earthworms to create a new type of Antimicrobial peptide feed raw materials and additives that can replace antibiotics have been tested on laying hens and fattening pigs and have achieved good results.

Earthworms have such a remarkable effect as animal feed, especially earthworms and their extracts are green and pollution-free, so the development and application of earthworm feed products have great potential and development prospects.

Advantages of Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer

| Industrial sized microwave Earthworm Tunnel Dehydrator Drying Machine | |

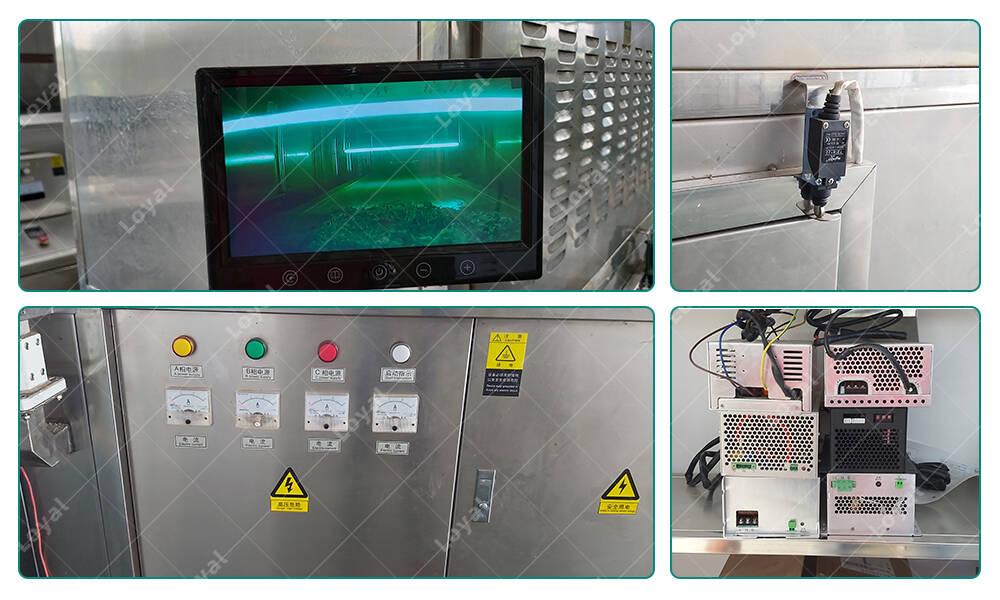

| 1 | Including feeding device, drying box, scraper, the feeding device is equipped with a gate, and the feeding device is equipped with a gate, which can adjust the feeding amount |

| 2 | There are more heaters in the front half of the drying box, which can quickly kill the earthworms that enter the drying box. A conveyor belt for conveying materials is arranged in the drying box. Both ends of the conveyor belt extend from the left and right ends of the drying box. A support beam is arranged under the conveyor belt in the drying box to prevent the earthworms from being too heavy to sag the conveyor belt; and equipped with baffles to prevent earthworms from falling |

| 3 | The right end of the drying box is provided with a drive motor for driving the conveyor belt, a number of heaters are arranged in the middle of the conveyor belt in the drying box, and there is a moisture outlet in the drying box corresponding to the position above the conveyor belt. |

| 4 | The moisture exhaust port is connected with a moisture exhaust fan through a pipeline. |

| 5 | The scraper includes a blanking plate, a scraper and a support arm. The left end of the scraper is set corresponding to the right end of the conveyor belt, and the scraper can hang the earthworms stuck on the conveyor belt. |

| 6 | The right end of the scraper is connected to the right end of the support arm through the blanking plate, and the left end of the support arm is fixed on the drying box. |

| 7 | A receiving box is set under the scraper. To collect earthworms |

Features of Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer

Although Insect Earthworm is an agricultural and sideline product, it has high requirements for microwave equipment, because the following indicators need to be met during the drying process.

| Industrial microwave for sale | |

| 1. High degree of puffing | If the puffing degree does not meet the requirements, the dried tenebrio molitor cannot even meet the basic requirements of the outlet. To achieve the ideal puffing degree, the microwave cavity needs to have a high power density, which increases the difficulty of design. And improve the parameter requirements of components. |

| 2. Beautiful color | The mealworms dried by good microwave drying equipment should be yellow, or close to the color of the insects themselves. The first requirement for designers is to have an understanding of the industry and rich design experience to be able to remove the mealworms. The processing technology is organically integrated into the design. |

| 3. High dryness | The microwave drying equipment uses microwaves to penetratingly heat the materials laid on the conveyor belt. Increase the temperature of the material in a short period of time, allowing the moisture contained in the material to evaporate naturally |

Quality parameters for Microwave Insect Earthworm Tunnel Dehydrator Drying Machine

| Quality parameters for fresh and dried BSFL | |||

| Quality parameters | Unit | Fresh larvae¹ | Dryed larvae¹ |

| Protein (with conversion factor 6.25) | % | 10.2±1 | 36.4±5 |

| Fat | % | 7.2±2 | 36.2±5 |

| Fibre | % | 3.2±1 | 13.5±4 |

| Ash | % | 1.8±0.5 | 7.0±4 |

| Carbohydrates | % | 1.4±1 | 6.2±2 |

| Moisture content | % | 76.5±3 | 2.6±0.8 |

| Water activity | - | 0.9±0 | 04±0.1 |

Customer Purchase Case Of Microwave Insect Earthworm Tunnel Dehydrator Drying Machine Dryer

Customer cases for industrial sized microwave for factory in 2021 | |

| 1 | 1t/h cost of microwave drying equipment sold in russia |

| 2 | 1t/h industrial microwave price for factory for sale in puerto rico |

| 3 | 1t/h industrial microwave price for sale in bolivia |

| 4 | Senegal 1t/h industrial fully automatic industrial sized microwave |

| 5 | 1t/h industrial sized Insect Earthworm microwave for sale in côte d'ivoire |

| 6 | China 300t/year industrial fully automatic industrial sized microwave |

Customer case of microwave Insect Earthworm drying equipment at 2021 | |

| 7 | 1t/h microwave drying equipment for factory in uzbekistan |

| 8 | 1000kg/h industrial microwave drying equipment for sale in senegal |

| 9 | Mozambique 1t/h fully automatic microwave drying equipment |

| 10 | Bangladesh 2t/h fully automatic microwave drying equipment |

Dealed customer have technology of microwave drying equipment at 2021 | |

| 11 | 1t/h thai microwave Insect Earthworm drying equipment for factory |

| 12 | Uzbekistan 1t/h fully automatic industrial microwave price |

| 13 | Usa 1t/h microwave drying equipment |

| 14 | 800kg/h industrial microwave Insect Earthworm drying equipment for sale in nigeria |