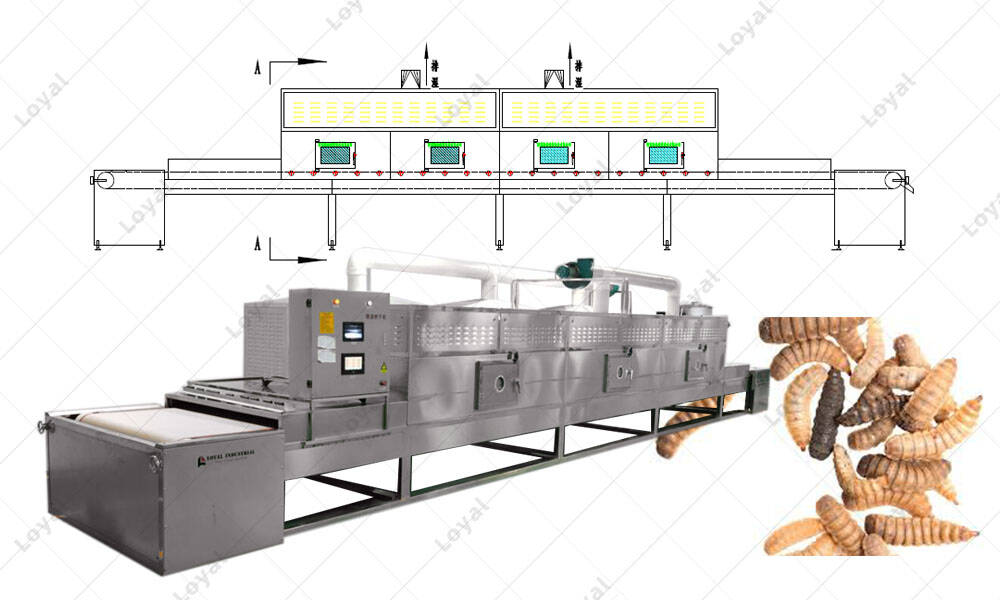

Conveyor Belt Type Black Soldier Fly Larvae Microwave Drying Machine

As one professional Conveyor Belt Type Black Soldier Fly Larvae Microwave Drying Machine manufacturer,we can offer small, medium and large conveyor belt type microwave oven for sale. The conveyor belt type microwave oven equipment has reasonable price, reliable quality and professional service! Our company provides customers full set service. Cost accounting, dryer design, raw material recipes, machine installation and debugging, design molds according to customer requirements.

Drying Black Soldier Fly Larvae with microwave drying equipment is a new drying technology. This technology has the advantages of fast drying speed and good quality. It has become the drying equipment for Black Soldier Fly Larvae for many Black Soldier Fly Larvae cultivators. This conveyor belt type microwave oven is used to drying tenebrio molitor, Black Soldier Fly Larvae, mealworm,etc. The insects treated by the microwave dryer are saturated, have a degree of expansion, and the appearance is better.

Conveyor Belt Type Black Soldier Fly Larvae Microwave Drying Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Microwave Drying Herbs Leaves Tea |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Industrial Conveyor Belt Type Microwave Oven For Black Soldier Fly Larvae |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sales Team | Microwave Drying Sterilizing Machine Process Technology Engineer |

Conveyor Belt Type Black Soldier Fly Larvae Microwave Drying Machine Detail Introduction :

Conveyor Belt Type Black Soldier Fly Larvae Microwave Drying Machine

Drying Black Soldier Fly Larvae with microwave drying equipment is a new drying technology. This technology has the advantages of fast drying speed and good quality. It has become the drying equipment for Black Soldier Fly Larvae for many Black Soldier Fly Larvae cultivators. This conveyor belt type microwave oven is used to drying tenebrio molitor, Black Soldier Fly Larvae, mealworm,etc. The insects treated by the microwave dryer are saturated, have a degree of expansion, and the appearance is better.

WHAT ARE FEATURES OF Black Soldier Fly Larvae Microwave Drying Machine?

Features Of Black Soldier Fly Larvae Microwave Drying Machine | |

| Drying | The Black Soldier Fly Larvae microwave dryer can be used to dry kinds of insects quickly and efficiently. |

| Sterilization | The fungus, mycetes and others can be killed by the microwave dryer during the drying process. |

| Fast And Evenly | The microwave dryer can change to be heat within several seconds,so the equipment is very efficient. |

| Safe | The Black Soldier Fly Larvae microwave dryer is passing in the metal covered rooms and wave guide without leaking. It will not generate extra heat and pollution. |

| Simple To Operate | The PLC system is simple, stable, safe and friendly,so it is convenient to use.

|

| Keeping Fresh | The sterilization is with lower temp, so the color of the material can be protected well. |

CONVEYOR BELT TYPE MICROWAVE OVEN DETAIL ADVANTAGE:

Advantage Of Black Soldier Fly Larvae Microwave Drying Machine | |

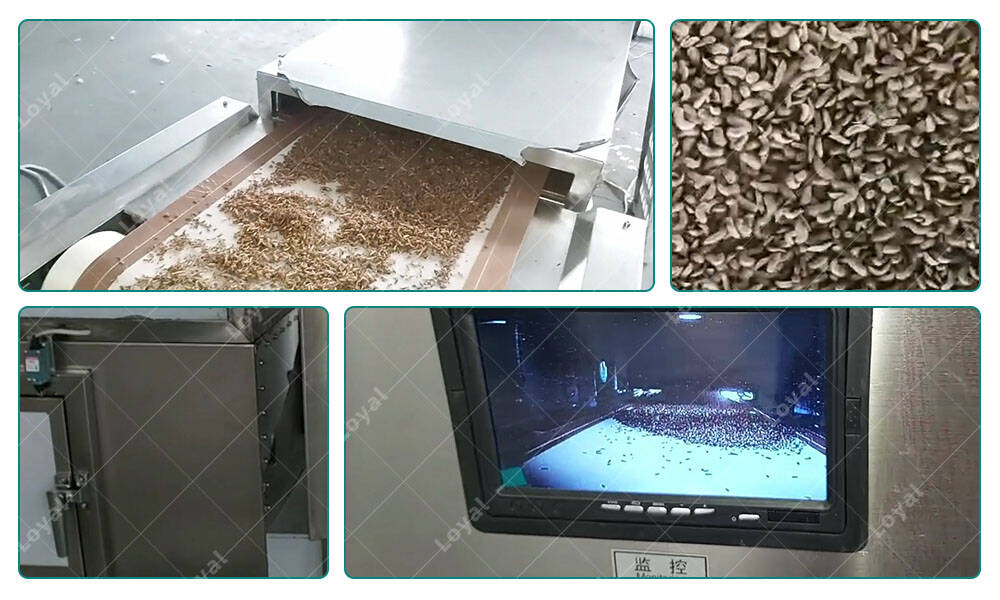

| 1 | By using PLC system and real time monitoring system, it is easy to operate. |

| 2 | The observation window design makes it easier to observe the internal situation. |

| 3 | The unique groove design prevents the conveyor belt from deviating. |

Quality parameters for Black Soldier Fly Larvae Microwave Drying Machine

| Quality parameters for fresh and dried BSFL | |||

| Quality parameters | Unit | Fresh larvae¹ | Dryed larvae¹ |

| Protein (with conversion factor 6.25) | % | 10.2±1 | 36.4±5 |

| Fat | % | 7.2±2 | 36.2±5 |

| Fibre | % | 3.2±1 | 13.5±4 |

| Ash | % | 1.8±0.5 | 7.0±4 |

| Carbohydrates | % | 1.4±1 | 6.2±2 |

| Moisture content | % | 76.5±3 | 2.6±0.8 |

| Water activity | - | 0.9±0 | 04±0.1 |

HOW TO DRY BLACK SOLDIER FLY LARVAE LARVAE?

The Black Soldier Fly Larvae microwave dryer can quickly dry the black soldier flies in batches. The dried black soldier flies are beautiful in color and can maintain a perfect appearance. After drying, the black soldier flies have low water content and are easy to grind. Good reservation.

Black soldier flies microwave dryer technology:

Live black soldier flies are put into the equipment feeding hopper →the black soldier flies are transported into the dryer cavity by the conveyor belt for drying → the equipment comes with strong wind cooling, cooling, drying and drying of the black soldier flies → entering Storage in bags.

The black soldier flies microwave dryer is conveyed by tunnel conveyor belt, continuous drying, and the drying temperature and drying speed can be adjusted linearly. The whole machine is made of stainless steel.

TECHNICAL PARAMETER OF CONVEYOR BELT TYPE MICROWAVE OVEN

Technical Parameter Of Conveyor Belt Type Microwave Oven | |||||

No. | Model | Power(Kw) | Dehydration Capacity(Kg/h) | Sterilization Capacity(Kg/h) | Size(Mm) |

1 | LY-12KWSP | 12 | 12 | 120-150 | 7010*840*1750 |

2 | LY-20KWSP | 20 | 20 | 190-240 | 9350*840*1750 |

3 | LY-30KWSP | 30 | 30 | 300-380 | 11690*840*1750 |

4 | LY-40KWSP | 40 | 40 | 390-500 | 10520*1060*1750 |

5 | LY-50KWSP | 50 | 50 | 500-630 | 11690*1060*1750 |

6 | LY-60KWSP | 60 | 60 | 600-750 | 12860*1060*1750 |

7 | LY-70KWSP | 70 | 70 | 700-870 | 14030*1060*1750 |

8 | LY-80KWSP | 80 | 80 | 800-1000 | 12680*1200*1750 |

9 | LY-100KWSP | 100 | 100 | 1000-1250 | 15200*1200*1750 |

10 | LY-150KWSP | 150 | 150 | 1500-1850 | 21050*1200*1750 |

11 | LY-200KWSP | 200 | 200 | 2000-2500 | 25050*1200*1750 |

WHICH MARKET DID THE LOYALSMALL SCALE BLACK SOLDIER FLY LARVAE MICROWAVE DRYER SOLD?

LOYAL's share of Black Soldier Fly Larvae microwave dryer exported to international markets has steadily increased. According to the export goods trade data in 2021, Loyal's export market share in the international market is 86.5%, of which the meat dryer export market share is 20.8%, the export market share in the Americas is 30.2%, and the export market share in Asia is 35.5%. If you are interested in a conveyor belt type microwave oven, please contact us today, we offer you the most cost-effective turnkey solution.

Customer Have Formula Request Of Microwave Black Soldier Fly Larvae Drying Plant | |

1 | China 300t/Year Industrial Black Soldier Fly Larvae Drying Machine |

2 | 1T/H Tough Black Soldier Fly Larvae Microwave Dryer For Sale In Puerto Rico |

3 | 1T/H Crisp Microwave Black Soldier Fly Larvae Drying Machine Line For Sale In Bolivia |

Cooperated Customer For Laboratory Machine Of Microwave Black Soldier Fly Larvae Drying Plant | |

1 | Senegal 200Kg/H Industrial Microwave Black Soldier Fly Larvae Drying Plant |

2 | 100-200Kg/H Conveyor Belt Type Microwave Oven For Sale In Côte d'Ivoire |

3 | 300-400Kg/H Conveyor Belt Type Microwave Oven Sold In Russia |

Cooperated Customer Request Engineer Installation At 2021 | |

1 | 1T/H Conveyor Belt Type Microwave Oven For Sale In Uzbekistan |

2 | 1000kg/h Industrial Automatic Black Soldier Fly Larvae Microwave Dryer For Sale In Senegal |

3 | Mozambique 1T/H Industrial Conveyor Belt Type Microwave Oven |

4 | 1T/H Thai Conveyor Belt Type Microwave Oven |

5 | Uzbekistan 1T/H Microwave Black Soldier Fly Larvae Drying Plant |

Cooperated Customer With Microwave Black Soldier Fly Larvae Drying Plant At 2021 | |

1 | Nigeria 150Kg/H Microwave Black Soldier Fly Larvae Drying Plant |

2 | Austria Sells Microwave Black Soldier Fly Larvae Drying Plant 100kg/h |

3 | Microwave Black Soldier Fly Larvae Drying Plant For Sale In Pakistan 100kg/h |