Chemical Material Drying Machine Silicon Carbide Graphite Polysilicon Microwave Drying Machine

As Chemical Material Drying Machine Silicon Carbide Graphite Polysilicon Microwave Drying Machine manufacturer in order to meet various market demands, our continuous microwave oven is summed by a number of silicon carbide graphite polysilicon microwave dryer technical engineers. Loyal a number of silicon carbide graphite polysilicon drying machine project technology patents, which can save silicon carbide graphite polysilicon microwave dryer costs while improving good development in the silicon carbide graphite polysilicon drying manufacturing industry.

Chemical Material Drying Machine Silicon Carbide Graphite Polysilicon Microwave Drying Machine Specifications :

| Price | Chemical Material Drying Machine Silicon Carbide Graphite Polysilicon Microwave Drying Machine |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Chemical Material Drying Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sales Team | Microwave Drying Sterilizing Machine Process Technology Enineer |

Chemical Material Drying Machine Silicon Carbide Graphite Polysilicon Microwave Drying Machine Detail Introduction :

As Chemical Material Drying Machine Silicon Carbide Graphite Polysilicon Microwave Drying Machine manufacturer in order to meet various market demands, our continuous microwave oven is summed by a number of silicon carbide graphite polysilicon microwave dryer technical engineers. Loyal a number of silicon carbide graphite polysilicon drying machine project technology patents, which can save silicon carbide graphite polysilicon microwave dryer costs while improving good development in the silicon carbide graphite polysilicon drying manufacturing industry.

What Is Microwave Drying?

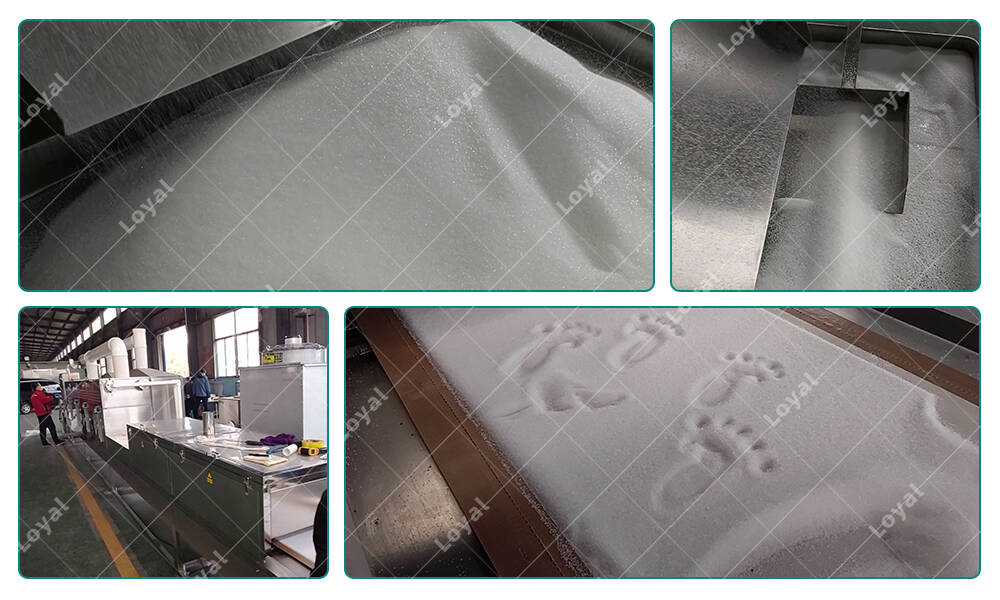

The chemical raw material silicon carbide graphite polysilicon dryer has good uniformity and low temperature. During the microwave heating process, the part of the chemical raw material silicon carbide graphite polysilicon with high water content absorbs more microwave power than the part with low water content. Therefore, the chemical raw material silicon carbide graphite polysilicon dehydration dryer drying equipment can achieve good drying uniformity, and the temperature of microwave drying materials is 85-100 degrees. The continuous production efficiency is high and the time is short. Safety, energy saving and environmental protection. The chemical raw material silicon carbide graphite polysilicon microwave dewatering dryer drying equipment occupies a small area. Because the chemical raw material silicon carbide graphite polysilicon drying equipment can be produced rapidly and continuously, the equipment occupies a small area. Advanced technology, instant start and stop, no thermal inertia. The chemical raw material silicon carbide graphite polysilicon microwave dehydration dryer drying equipment can be equipped with an assembly line with superior performance. In addition, because microwave drying does not need to provide a heat source, it only needs to heat and dry the chemical raw material silicon carbide, graphite and polysilicon, so the equipment has no thermal inertia and can be turned on and off immediately.

What Is The Technical Parameters Of Silicon Carbide Graphite Polysilicon Microwave Drying Machine?

| Technical Parameters Of Silicon Carbide Graphite Polysilicon Microwave Drying Machine | |||||

| No | Modle | Sterilization Capacity(Kg/h) | Power | Size L*W*H(mm) | Dehydration Capacity(Kg/h) |

| 1 | LY-12KW | 120-150kg/h | 12KW | 7010mm*840mm*1750mm | 12kg/h |

| 2 | LY-20KW | 200-240kg/h | 20KW | 9350mm*840mm*1750mm | 20kg/h |

| 3 | LY-40KW | 400-500kg/h | 40KW | 10520mm*1060mm*1750mm | 40kg/h |

| 4 | LY-80KW | 800-1000kg/h | 80KW | 12860mm*1200mm*1750mm | 80kg/h |

| 5 | LY-100KW | 1000-1250kg/h | 100KW | 15200mm*1200mm*1750mm | 100kg/h |

Parameter of 30 KW Silicon Carbide Graphite Polysilicon Microwave Drying Machine

Parameter of 30 KW Silicon Carbide Graphite Polysilicon Microwave Drying Machine | ||

| 1 | Equipment Working Power Supply | Three-Phase Five-Wire 380V |

| 2 | Microwave Operating Frequency | 2450Mhz |

| 3 | Drying Temperature | 80-120 Degrees (Adjustable And Controllable) |

| 4 | Height Of Inlet And Outlet | 50mm |

| 5 | Conveyor Belt Width | 750mm |

| 6 | Microwave Leakage | Gb ≤5mw/c㎡ |

| 7 | Dimensions (Length*Width*Height) | About 12800*362*750mm |

| 8 | Execution Standard | Microwave leakage meets the national gb10436-89 standard and meets the national GB5226 electrical standard |

| 9 | Transmission Speed | 0 ~ 5 m/Min (Frequency Conversion Speed Regulation) |

Features Of Silicon Carbide Graphite Polysilicon Microwave Drying Oven

| Features Of Silicon Carbide Graphite Polysilicon Microwave Drying Oven | |

| No. | Features Of Silicon Carbide Graphite Polysilicon Microwave Dryer |

| 1 | The microwave drying time is short and the speed is fast. Microwave drying is completely different from the traditional drying method. Microwave drying is a process that makes the dried material itself become a heating element without it is a material with poor thermal conductivity, microwave drying can reach the heating temperature in a very short time, so as to achieve rapid drying. |

| 2 | Uniform microwave drying. Regardless of the shape of each part of the object, microwave heating can make the surface and the inside of the object evenly penetrate and absorb electromagnetic waves to generate heat energy, so the heating and drying uniformity is good, and the phenomenon of external coke will not appear. |

| 3 | Microwave is energy-saving, environmentally friendly, and highly efficient. Because water-containing substances easily absorb microwave and generate heat, there is almost no other loss except for a small amount of transmission loss, so it has high thermal efficiency and energy saving. It saves more than 1/3 of infrared heating. |

| 4 | Advanced microwave technology. Start and stop immediately, as long as the microwave power is controlled, immediate heating and termination can be achieved. |

Application Of Silicon Carbide Graphite Polysilicon Industrial Microwave Oven

Application Of Silicon Carbide Graphite Polysilicon Microwave Drying Oven | |

NO. | Application Of Silicon Carbide Graphite Polysilicon Industrial Microwave Dryer |

1 | Chemical Material,Medicine Tablet Or Pill, Such As Watered Pills,Water-Honey Bolus,Honeyed Bolus,Condensed Pill And Tibetan Pill,Etc. |

2 | Chemical Material,Medicine Tablet Or Pill,Such As Watered Pills,Water-Honey Bolus,Honeyed Bolus,Condensed Pill And Tibetan Pill,Etc. |

3 | Snack Food, Fruit Seeds, Grains, Peanuts, Chips, Etc. |

4 | Powder For Various Material,Such As Spices, Other Food Additives. |

5 | Agricultural Products,Such As China Date,Nuts,Grains, Peanut,Etc |

6 | Various Dried Meat, Like Beef, Pork, Chicken,Duck, Fish Etc. |

2021 Customer Order Silicon Carbide Graphite Polysilicon Microwave Drying And Sterilizing Machihne Form:

| Customers Who Understand The Silicon Carbide Graphite Polysilicon Drying Machine Processing Technology | |

| 1 | Silicon Carbide Graphite Polysilicon Hot Air Dryer Granulator Drying Equipment For Instant Electuary For Sale In Afghanistan |

| 2 | China Fully Silicon Carbide Graphite Polysilicon Dryer Vacuum Microwave Machine Dryer Machine Industrial Microwave Oven For Sale In Argentina |

| 3 | High Quality Most Popular Industrial Continuous Microwave Silicon Carbide Graphite Polysilicon Drying Machine Tunnel Microwave Dryer For Sale In Comoros |

| 4 | Mini Industrial Silicon Carbide Graphite Polysilicon Making Machine Spray Dryer Drying Machine For Sale In Afghanistan |

| 5 | Chemicals Drying Equipment Silicon Carbide Graphite Polysilicon Dryer Industrial Pesticide Farm Chemicals Drying Equipment For Sale In Argentina |

Dealed Customers Who Purchase Big Output Silicon Carbide Graphite Polysilicon Dryer Production Line In 2021 | |

| 1 | Customized Microwave Vacuum Drying Sterilization Silicon Carbide Graphite Polysilicon Equipment For Chemical Industry For Sale In Congo |

| 2 | 50Kw Chemical Silicon Carbide Graphite Polysilicon Microwave Drying Machine Equipment For Silicon Carbide Graphite Polysilicon For Sale In Denmark |

| 3 | Tunnel Industrial Microwave Silicon Carbide Graphite Polysilicon Drying Sterilization Machine Equipment For Sale In Congo |

| 4 | Customized High Efficiency Silicon Carbide Graphite Polysilicon Drying Equipment Silicon Carbide Graphite Polysilicon For Chemical Industry For Sale In India |

| 5 | Silicon Carbide Graphite Polysilicon Microwave Sterilization Drying Equipment For Sale In Denmark |

Dealed Customer Have Plant Of Silicon Carbide Graphite Polysilicon Drying Equipment In 2021 | |

| 2 | Tunnel Industrial Chemical Silicon Carbide Graphite Polysilicon Microwave Drying Equipment For Sale In Fiji |

| 3 | High Efficient Microwave Industrial Silicon Carbide Graphite Polysilicon Drying Machine Industrial Microwave Dryer For Sale In Germany |

| 4 | High Efficient Microwave Industrial Silicon Carbide Graphite Polysilicon Drying Machine Industrial Microwave Dryer For Sale In Germany |

| 5 | Belt Tunnel Drying Machine Silicon Carbide Graphite Polysilicon Microwave Dryer Machine For Sale In Germany |

Dealed Customer Cooperated Agent Of Silicon Carbide Graphite Polysilicon Drying Production Line In 2021 | |

| 1 | Stainless Steel Silicon Carbide Graphite Polysilicon Spray Dryer Price Stainless Steel Spray Dryer For Sale In Laos |

| 2 | High Efficient Microwave Industrial Silicon Carbide Graphite Polysilicon Drying Machine Industrial Microwave Dryer For Sale In Germany |

| 3 | High Efficient Microwave Industrial Silicon Carbide Graphite Polysilicon Drying Machine Industrial Microwave Dryer For Sale In Germany |

| 4 | Chemical Products Silicon Carbide Graphite Polysilicon Microwave Conveyor Belt Dryer Machine For Sale In Mali |

| 5 | Silicon Carbide Graphite Polysilicon Drying Box Braised Meat Tray Dryer Machine Grain Drying Equipment For Sale In Nauru |