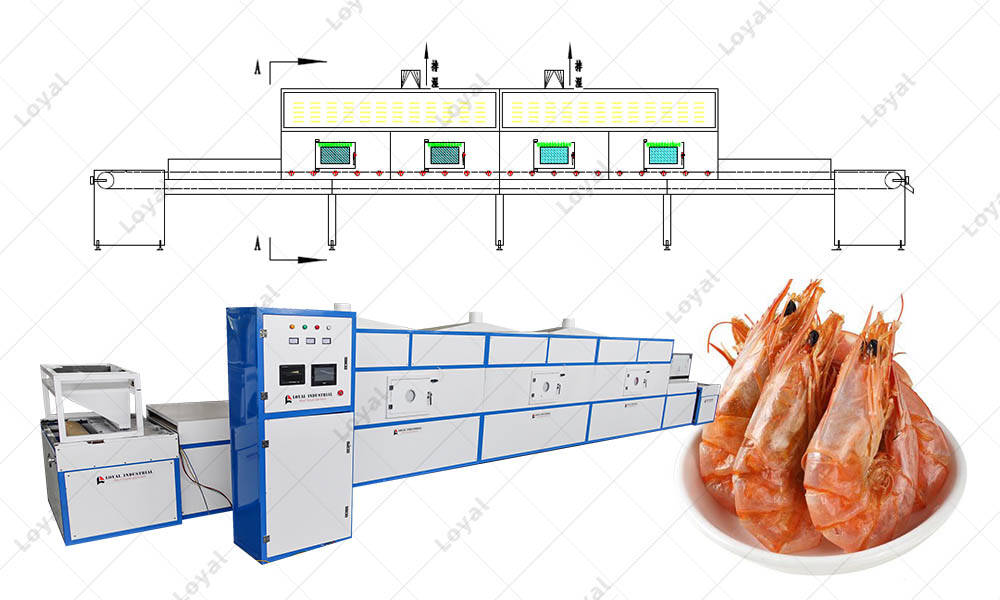

60Kw High Quality Industrial Continuous Microwave Shrimp Drying Machine

As a professional high quality industrial continuous microwave shrimp drying machine suppliers, our continuous microwave shrimp drying machine are widely used, microwave dryer is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating.

Industrial continuous microwave shrimp drying machine is more and more popular nowadays. Microwave shrimp drying machine energy is converted into direct effects on heat. Cook shrimp in microwave has penetrating performance inside and outside the media heating at the same time. Microwave frozen shrimp can saving drying time and aviod the raw material becoming metamorphism or coking the overheat environment. The microwave shrimp drying effect is good for seafood, tea, mushroom and so on.

60Kw High Quality Industrial Continuous Microwave Shrimp Drying Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | 60Kw High Quality Industrial Continuous Microwave Shrimp Drying Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Delivery Detail | 20days/Microwave equipment assembly completed |

| Packaging Details | Export-compliance microwave equipment packaging |

| Team | Professional microwave technology team |

| Technology | 8 years of microwave technology |

| Honor | A number of national microwave equipment patents |

| Process | Ten years of microwave equipment manufacturing process |

60Kw High Quality Industrial Continuous Microwave Shrimp Drying Machine Detail Introduction :

60Kw High Quality Industrial Continuous Microwave Shrimp Drying Machine

As a professional high quality industrial continuous microwave shrimp drying machine suppliers, our continuous microwave shrimp drying machine are widely used, microwave dryer is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating.

Industrial continuous microwave shrimp drying machine is more and more popular nowadays. Microwave shrimp drying machine energy is converted into direct effects on heat. Cook shrimp in microwave has penetrating performance inside and outside the media heating at the same time. Microwave frozen shrimp can saving drying time and aviod the raw material becoming metamorphism or coking the overheat environment. The microwave shrimp drying effect is good for seafood, tea, mushroom and so on.

What Is The Technical Parameters Of High Quality Industrial Continuous Microwave Shrimp Drying Machine?

Model No. | Over Size(m) | Power(Kw) | Dehydration Capacity(Kg/h) | Sterilization Capacity(Kg/h) |

LY-20 | 9*0.9*2.2 | 20 | 20 | 190-240 |

LY-40 | 10*1.0*2.2 | 40 | 40 | 390-500 |

LY-60 | 12*1.0*2.2 | 60 | 60 | 600-750 |

LY-100 | 15*1.2*2.2 | 100 | 100 | 800-1000 |

LY-150 | 21*1.2*2.2 | 150 | 150 | 1500-1850 |

LY-200 | 25*1.2*2.2 | 200 | 200 | 2000-2500 |

Drying case of Industrial Continuous Microwave Shrimp Drying Machine:

Application : Microwave dryer has four function -drying ,ripening, fixation, sterilization ,down below is our different material working case.

No. | Machine Parts Of Industrial Continuous Microwave Shrimp Drying Machine |

1 | Microwave dryer host |

2 | Microwave generator system |

3 | Humidity controlling system |

4 | Transmission Parts |

5 | PLC and touch screen control panel |

6 | Observation windows |

7 | Humidity discharging system |

8 | Electrical control cabinet |

9 | Cooling system |

10 | Hot air recycling and circulation system |

Regarding The Cook Prawns In Microwave , Customers Usually Encounter Problems:

Q: What Is The Best Way To Dry Shrimp ?

A:Then best way is use industrial microwave shrimp drying machine , because the drying speed of the microwave drying oven is usually increased by several times, and the production efficiency of the enterprise will be greatly improved. Themicrowave shrimp drying energy consumption is usually reduced by more than 50%, which can effectively reduce the production cost of the enterprise.the tunnel microwave shrimp drying machine microwave dryer realizes uniform drying of materials and pollution-free, and at the same time, it can greatly reduce the drying temperature.

Q:What Is The Difference Between Air-Cooled Magnetron And Water-Cooled Magnetron In Cook Prawns In Microwave ?

A:Water-cooled magnetron for continuous non-stop operation. Air-cooled magnetron can not work without interruption, but the price is lower than water-cooled magnetron. This type of magnetron is suitable for low power machine, or the areas with low ambient temperature.

Q:How Do I Dry Fish Or Shrimp ?

A:Use tunnel shrimp microwave drying machine, put fish or shrimp are uniformly distributed on the mesh belt by the material feeder and it is drawn by a transmission device and move inside the dryer. For each section, the hot air is circulated separately. Part of exhausted gas is exhausted by a special moisture exhaust blower. The hot air passes through the mesh-belt covered with bring water material away. The mesh-belt moves slowly, running speed can be freely adjusted according to the material property. The final rosemary after the drying process will fall into the material collector continuously.

Which Market Did The Loyal Industrial Microwave Shrimp Drying?

A Number Of Microwave Shrimp Drying Equipment Patents Clients | |

1 | 100kg/htunnel shrimp microwave drying machine for austria |

2 | 20kw small industrial microwave oven for sale in uzbekistan |

3 | 80kg/h microwave dryer microwave fish drying drying machine for sale in bahrain |

4 | 30kw microwave fish products drying machineto spain |

5 | 200kg/h tunnel shrimp microwave drying machine to st. Lucia |

6 | 100kw small industrial microwave dryer to togo |

7 | 70kw seafood industrial microwave dryer to taiwan, china |

Customer Case Of Shrimp Fish Dryer At 2021 | |

1 | 60kw Microwave drying machine 100kg/h in belarus |

2 | 50kg/h tunnel shrimp microwave drying machine for sale in austria |

3 | 100kg/h shrimp microwave drying to sri lanka |

4 | 500-600 Fish industrial belt dryer to nited arab emirates |

5 | 100kg/h tunnel shrimp microwave drying machine sold in russia |

Customer Have Factory Case Of Industrial Drying Equipment At 2021 | |

1 | 200kg/h industrial microwave oven for sale in bolivia |

2 | Mozambique 150kg/h industrial fish drying equipment to lithuania |

3 | 300kg/h industrial continuous belt dryer for sale in portugal |

4 | Mozambique 250kg/h industrial seafood drying equipment |

5 | 60kw seafood industrial automatic industrial belt dryer for sale in North Korea |