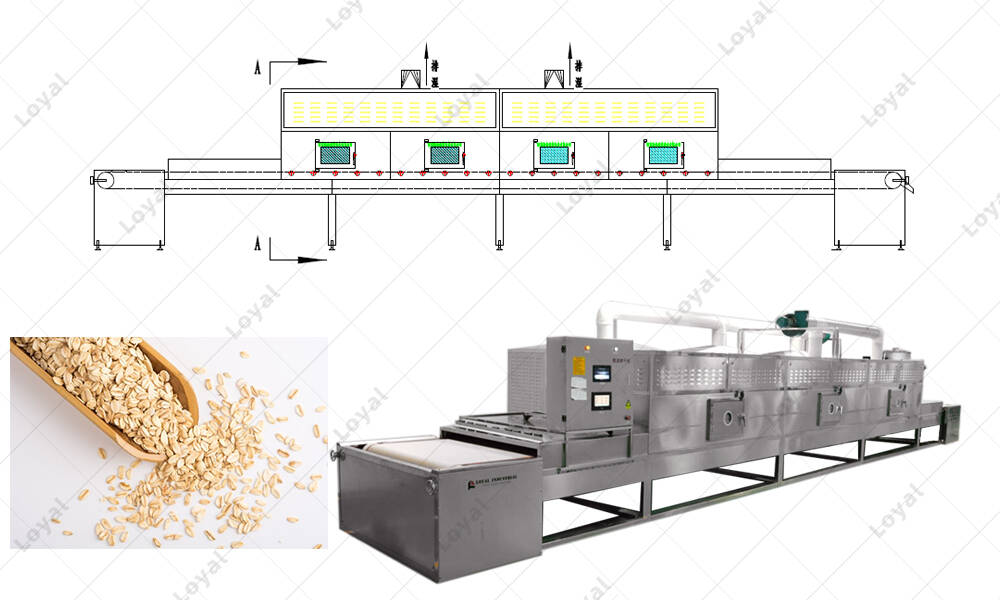

90 Kw Full Automatic Tunnel Oatmeal Microwave Sterilization Drying Machine

As a professional full automatic tunnel oatmeal microwave sterilization drying machine suppliers, The oatmeal microwave drying equipment produced by our company are mainly used for drying and sterilization in the industries of food, chemical industry, condiments, pharmaceuticals, rubber latex products, wood, paper, ceramics, tea, tobacco and other industries. Industrial microwave dryer has a fast drying speed, high efficiency and short time. The continuous microwave tunnel belt dryer also have stabilization function, which can extend the shelf life of the grains and improve the quality of the grains. In addition, the industrial continuous microwave oatmeal sterilization drying machine belongs to energy-saving and environment-friendly equipment.

90 Kw Full Automatic Tunnel Oatmeal Microwave Sterilization Drying Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 3days--7days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

90 Kw Full Automatic Tunnel Oatmeal Microwave Sterilization Drying Machine Detail Introduction :

As a professional full automatic tunnel oatmeal microwave sterilization drying machine suppliers, The oatmeal microwave drying equipment produced by our company are mainly used for drying and sterilization in the industries of food, chemical industry, condiments, pharmaceuticals, rubber latex products, wood, paper, ceramics, tea, tobacco and other industries. Industrial microwave dryer has a fast drying speed, high efficiency and short time. The continuous microwave tunnel belt dryer also have stabilization function, which can extend the shelf life of the grains and improve the quality of the grains. In addition, the industrial continuous microwave oatmeal sterilization drying machine belongs to energy-saving and environment-friendly equipment.

90 Kw Full Automatic Tunnel Oatmeal Microwave Sterilization Drying Machine For Sale

Continuous conveyor belt microwave oatmeal drying machine is a new type of drying equipment with high production efficiency and low operating cost. industrial microwave oven is also an efficient and environmental friendly energy-saving equipment; especially for foods that contain bactericidal and fresh-keeping functions while drying. The microwave is an electromagnetic wave has a frequency of 300MHz-300GHz. This microwave oven with sterilization has been widely involved in the pharmaceutical, food, chemical, building materials and other industries.

What Is The Structure Of The Full Automatic Tunnel Oatmeal Microwave Sterilization Drying Machine ?

The system composition of microwave oatmeal drying equipment: microwave heating cavity, microwave generator, microwave suppressor, material conveying system, control and detection system, moisture removal, electrical components heat removal and other systems.

The Structure Of The Industrial Continuous Microwave Oatmeal Sterilization Drying Machine | ||

| 1 | Microwave heating system | ♦Microwave heating boxes is 304 stainless steel. ♦In order to facilitate cleaning and operation, the box body is favorable for the discharge of the gas to be cleared. ♦The top has a wet discharging hole, with a wet exhaust hood. Inter layer gas exchange. |

| 2 | Microwave suppression system | ♦The machine equipped with microwave suppressor to prevent microwave leakage. |

| 3 | Transmission system | ♦Transmission motor, frequency control, speed adjustable. ♦Using Teflon high-temperature microwave special conveyor belt, pneumatic deviation device,directional guide, without correction. |

| 4 | Cooling,exhaust system | ♦Equipment cooling system:using closed cooling tower. ♦Equipment exhaust system:environmental low-noise centrifugal fan. |

| 5 | Control and detection system

| ♦The equipment control system adopts intelligent PLC ♦Equipped with infrared radiation thermometer, far infrared probe temperature range: (0 ~ 300 degrees). |

What Are The Preparations For The Use Of The Continuous Microwave Tunnel Belt Dryer?

1. Check whether the power supply of the equipment is normal, and the equipment must be well grounded.

2. Observe that the door is closed properly.

3. Put all control switches on the control panel to the "off" state;

4. Prepare the materials;

5. Close the main power air switch;

6. Set the display adjustment on the panel of the speed regulating motor controller to the zero state;

What Are The Features Of The Oatmeal Microwave Drying Equipment?

The Features Of The Continuous Conveyor Belt Microwave Oatmeal Drying Machine |

| 1. The drying time is short, and the fragrance of the product is strong; |

| 2. The drying temperature is low and uniform, and the color of the product is bright; |

| 3. It has the advantages of fast drying speed, uniform heating, no deformation, good quality, and is conducive to production; |

| 4. The direction of water vapor in drying and dehydration is from inside to outside. Therefore, microwave drying has a puffing effect, which is of great help to the subsequent pulverization; |

| 5. The speed of microwave drying of food is much 20-30 times faster than that of traditional drying; energy consumption is reduced by more than 25% compared with far-infrared and steam drying. |

| 6. Easy to control, advanced technology, the equipment is ready to use; no thermal inertia, flexible and convenient operation; adjustable power of microwave drying equipment, no waste water, no waste gas, is a safe and harmless high-tech equipment. |

What Is The Temperature To Microwave Dry Oatmeal?

Low-temperature drying and sterilization equipment for oatmeal can kill all Escherichia Coli at 70°C. The total number of bacteria is greatly reduced at 80-90°C, and the time is only 2-3 minutes. The oatmeal microwave drying equipment drying and sterilizing speed is fast and the time is short, so the nutrients and traditional flavors in the food are preserved. Extending the shelf life has a significant effect on improving product quality.

The technical parameter of the Full Automatic Tunnel Oatmeal Microwave Sterilization Drying Machine | |||||||

Microwave output frequency | 2450 ± 50MHZ | ||||||

Temperature range | 0-200℃ | ||||||

Relative humidity | ≤80% | ||||||

Power supply | 380V,50Hz | ||||||

Models | Working Frequency | Input power (no more than) | Output power (no less than) | Size (mm) | Dehydrated Level | Sterilization Capacity | |

LY-12 | 2450MHz | 18kw | 12kw | 7200x650x1800 | 12kg/hr | 100-150 kg/hr | |

LY-15 | 2450MHz | 20kw | 15kw | 8300x720x1800 | 15kg/hr | 120-180 kg/hr | |

LY-20 | 2450MHz | 26kw | 20kw | 8500x750x1800 | 20kg/hr | 180-250 kg/hr | |

LY-30 | 2450MHz | 36kw | 30kw | 10500x950x2000 | 30kg/hr | 280-350 kg/hr | |

LY-40 | 2450MHz | 46kw | 40kw | 10500x1050x2000 | 40kg/hr | 380-450 kg/hr | |

LY-50 | 2450MHz | 58kw | 50kw | 12200x1200x2000 | 50kg/hr | 480-550 kg/hr | |

LY-60 | 2450MHz | 68kw | 60kw | 13500x1200x2000 | 60kg/hr | 500-600 kg/hr | |

LY-70 | 2450MHz | 78kw | 70kw | 13500x1550x2000 | 70kg/hr | 700-800 kg/hr | |

LY-80 | 2450MHz | 90kw | 80kw | 15500x1550x2000 | 80kg/hr | 800-900 kg/hr | |

LY-100 | 2450MHz | 110kw | 100kw | 16500x1750x2000 | 100kg/hr | 1000-1200kg/hr | |

The Application Of The Full Automatic Tunnel Oatmeal Microwave Sterilization Drying Machine

1. Chemical material, medicine tablet or pill, such as watered pills,water-honey bolus, honeyed bolus, condensed pill,etc.

2. All kinds of teas, herbs, flowers, green leaves, etc.

3. Various dried meat, like beef, pork, chicken,duck, fish etc.

4. Powder for various material, such as spices, nutrition power, other food additives.

5. Agricultural products, such as china date, nuts, grains, peanut, etc

6. Snack food, fruit seeds, grains, peanuts, chips, etc.

7. Insects, grasshoppers, black soldier flies, mealworms, etc.

What Kind Of Full Automatic Tunnel Microwave Sterilization Drying Machine Has Been Loyal Sold In 2021 ?

Customer Case Of The Full Automatic Tunnel Microwave Sterilization Drying Machine In 2021 | |

1 | Industrial Continuous Vegetable Leaves Drying Equipment Microwave Dryer For Sale Senegal |

2 | Black Soldier Fly Larvae Mealworm Microwave Dryer Equipment For Sale Nigeria |

3 | Green Leaves Tunnel Belt Industrial Microwave Drying Machine For Sale Burkina Faso |

4 | 50kw Beef Continuous Microwave Dryer Industrial Microwave Drying Sterilization Machine For Sale Botswana |

Customer Case Of Microwave Drying Dehydration Machine Manufacturing At Discount Prices In 2021 | |

1 | 800-1000kg/H Microwave Nut Pistachios Seed Baking Curing Drying Sterilizing Equipment For Sale Mozambique |

2 | Commercial Herbs Industrial Microwave Drying Equipment For Sale Austria |

3 | Industrial Breadworm Tenebrio Mealworm Insect Microwave Drying Equipment For Sale Moldova |

4 | Industries And Commercial Stainless Steel Microwave Fruit Drying Dryer Equipment For Sale Ukraine |

5 | Medicine Tablet Microwave Drying Machine For Sale Singapore |

Repurchase Case Customer With The I Continuous Microwave Dryer Technology In 2021 | |

1 | 200kg/H Green Leaves Microwave Drying Technology Machine For Sale Puerto Rico |

2 | Industrial Continuous Microwave Paprika Powder Sterilization Drying Machine Bolivia |

3 | Plc Control Industrial Tunnel Continuous Microwave Puffed Prawn Cracker Microwave Machine For Sale Dominica |

4 | 30Kw Tunnel Conveyor Belt Type Automatic Industrial Tunnel Cat Litter Microwave Sterilizing Drying Machinefor Sale In Senegal |

5 | 150Kg/H Nuts Industrial Drying Machine Price In Nigeria |

Transaction Case Customer Of The Industrial Tunnel Microwave Drying Machine In 2021 | |

1 | Fiberglass Insulation Board Fully Automatic Industrial Microwave Drying Machine For Sale Thailand |

2 | Uzbekistan 250kg/h Leaves Microwave Drying Equipment For Sale Uzbekistan (Tashkent) |

3 | 300-500kg/H Fruit Seeds Microwave Dryer Manufacturing Equipment For Sale Uzbekistan |

4 | 80-100kg/H Flowers Tunnel Belt Microwave Drying Equipment For Sale With New Technology |

5 | Black Soldier Larva Microwave Dryer Drying Equipment For Sale Zimbabwe |

6 | 80kw Bean And Nuts Microwave Drying And Sterilization Equipment For Sale Turkmenistan |