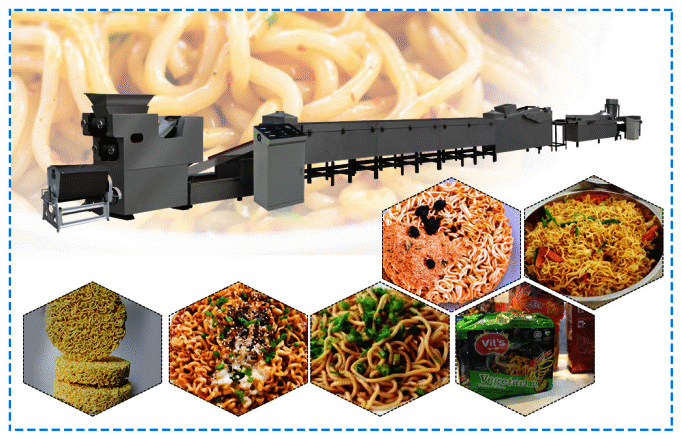

Full Automatic 11000pcs/ 8hours Instant Noodles Production Line

Instant noodles processing line, with perfect technology, compact structure, original design and stable performance, is developed on the basis of advanced products and requirements in the world market. Instant noodles processing line can be tailored according to client certain requirement.Instant noodles production line with perfect technology, compact structure, original design and stable performance, is developed on the basis of advanced products and requirements in the world market. It realizes high automation, convenient operation, low energy and small floor space, which assures all working procedures from feeding flour to finished products can be accomplished once. The investment on this line is only one tenth of that larger size equipment, especially suitable to small-size or self-owned enterprises. manufacturing instant noodles is tenacious smooth and transparent.

Full Automatic 11000pcs/ 8hours Instant Noodles Production Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Full Automatic 11000pcs/ 8hours Instant Noodles Production Line Detail Introduction :

Instant noodles processing line, with perfect technology, compact structure, original design and stable performance, is developed on the basis of advanced products and requirements in the world market. Instant noodles processing line can be tailored according to client certain requirement. The investment for instant noodle machine is only one tenth of that larger size equipment, especially suitable to small size or self-owned enterprises. The corrugated instant noodle produced by this line is tenacious smooth and transparent.

Technical Parameters Of Instant Noodles Machine

| Technical Parameters Of Instant Noodles Machine | ||||

| DIFFERENT INSTANT NOODLES MAKING MACHINES PARAMETERS | ||||

| Model | Power | Steam Consumption | Workman requirement | Size |

| 30,000bags/8h | 42KW | 1000-1200KG/H | 5persons/shift | L45m*W5m*H2.5m |

| 60,000bags/8h | 56KW | 1200-1400KG/H | 6persons/shift | L49m*W5m*H2.5m |

| 80,000bags /8h | 68KW | 1300-1500KG/H | 7persons/shift | L56m*W5m*H2.5m |

| 120,000bags/8h | 83KW | 1600-1800KG/H | 8persons/shift | L60m*W6m*H3m |

Instant noodles become one of the major modern food consumption, as its convenient, diverse tastes to meet the people's demand for food.

Our company specialize in the production of instant noodles production line. Design and provide different productivity equipment, fried type and non-fried instant noodles production line, to meet the customer's different kinds of requirements. Also, the instant noodle production line can be customized according to customer specific requirement.

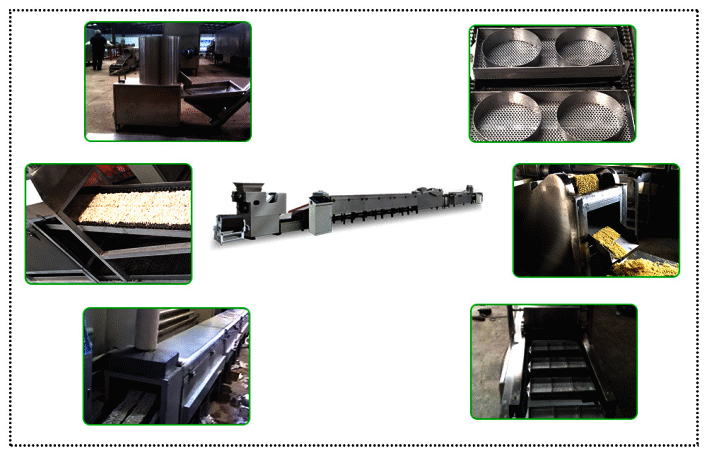

HOW TO MAKE INSTANT NOODLES ?

Flow Chart Of Instant Noodles Machine

Mixing Material - Rolling&Shaping- Boiling - Cutting and bending - Frying - Cooling - Ready the flavoring bags-Packaging

| The Process Of Instant Noodles Machine | |

| Machine | Application/ Use |

| Dough maker | Mixing flour and water evenly into dough |

| Roller processing machine | Rolling and shaping dough into noodle shape |

| Steaming Machine | Boiling noodles |

| Cutting machine | Cutting the boiled noodle into different shape(round or square) |

| Fryer | Fried boiled noodles to shape and taste delicious |

| Cooler | cooling fried noodles |

| Packing Machine | To packing the finished noodles |

Instant Noodle Extruder Machine Plant Working Description:

| Instant Noodle Extruder Machine Plant Working Description | |

| Operation | Description |

| 1.Mix into dough | Put the prepared flour and water,salt into the dough mixer, and then continue to mixing until the dough is mixed |

| 2.Rolling dough | The dough passes through multiple rolling rollers continuously, to be a layer |

| 3.Cutting extruded noodles | In order to make noodles curved, noodles are cut into curved noodles through an instant noodle forming knife |

| 4.Steamed raw noodles | The cut raw noodles pass through a long steaming box, while steaming, the speed of the conveyor belt is increased, and the noodles are gradually pulled into the whole process, whole processing only takes two minutes |

| 5.Paint oil on the surface of the noodles | Paint oil on the surface of the noodles to prevent the dough from sticking together. The noodles were elongated in the previous step, so that the oil can be applied more evenly. |

| 6.Cut into one piece | The noodles coated with oil are cut by a rotary knife, the portion cut in one circle is one piece. Usually the length of the cutted noodles is 30cm, which is the most suitable length for people to grip when eat. |

| 7.Serving a single serving of noodles | Each cutted noodle will be individually placed in a perforated stainless steel filter on the frying machine, waiting to be fried. |

| 8.Frying noodles | Each piece of noodles is thoroughly fried at an oil temperature of 130°C ~ 140°C to complete the dehydration and hardening process.Required oil volume is 1200kg. |

| 9.Cooling process | The fried noodle cakes are very hot , need to be cooled in an air-cooling cooler to 35℃ ~ 40℃. |

Main Features Of Instant Noodle Extruder Machine

| Main Features Of Instant Noodle Extruder Machine | |

| ITEM | MAIN FEATURES OF INSTANT NOODLE LINE |

| 1 | Instant noodle line adopt food-grade stainless steel, which is longer service life and neatness |

| 2 | All motors and spare parts adopt the famous brand,to ensure the strong quality |

| 3 | Pressing & Shaping Machine, Cutting Machine and Frying Machine are all frequency control. |

| 4 | The size of noodles can be adjusted easily. |

| 5 | High automation, convenient operation, low energy and small floor space. |

| 6 | Easy operation ,3-4 workers enough |

| 7 | Compact structure ,Small footprint |

| 8 | Instant noodle can be packed in bag or cup for sales. |

| 9.Cooling process | The fried noodle cakes are very hot , need to be cooled in an air-cooling cooler to 35℃ ~ 40℃. |

| 10.Inspection | Weigh the noodles first, to check if its meet the standards, and then check whether they are mixed with metal or other substances by X-ray machine. Most of them also need to manually check whether the shape of the noodles is normal. |

| 11.Put the flavoring bags/oil bags | After each noodles cake passes through the material package machine on the conveyor belt, a package of seasoning package is placed on it. |

| 12.Instant noodles Packing | The packaging bag is marked with the production date by a V-shaped machine, then the noodles are wrapped, and finally each side is divided and sealed by a heat-sealing hob at the end of the assembly line. |

| 13.Second-quality inspection | The packaged surface must be weighed and irradiated by X-ray machine, and the package must be manually checked for leaks, offsets, discoloration and other problems. |

| 14. Third-quality inspection(by worker) | Artificial edible tasting, to detect whether the taste of instant noodles is good enough. |

FINISHED PRODUCTS PICTURES:

Application:Japanese Instant Noodles,Taiwan Instant Noodles, Yamato Noodle Machine, China Instant Noodles

We can provide you the seasons bag packing equipment. To loading seasoning powder and also oil.

Customer Cases for instant noodles production line in 2021

| 30000pcs/8 H industrial instant noodles production line for sale in Uzbekistan |

| 60000/8h industrial automatic instant noodles production line for sale in Senegal |

| Mozambique 30000PCS/8H Industrial instant noodles manufacturing process |

| Bangladesh 80000pcs/8h Industrial Industrial instant noodles manufacturing process |

| 60000PCS/8H Thai manufacturing instant noodles Production Line |

| 11000PCS/8H Small raw materials for noodles production For Sale Botswana |

| LYFISH-5 raw materials for noodles production for sale Pakistan |

| Small 200kg/h ingredients of instant noodles production line Moldova |

| 60000pcs/8h instant noodle processing line for sale Ukraine |

| 11000pcs/8h small electric instant noodle processing line for sale Singapore |

| 11000pcs/8H instant noodle production line For Sale Puerto Rico |

| 30000pcs/8h instant noodle line machine for sale Bolivia |

| 60000pcs/8h instant noodle line For Sale Dominica |

| 40000pcs/8h instant noodle line in Senegal |

| 100000KG/H noodles production line In Nigeria |

| 11000/8H noodles production line For Sale Cote d'Ivoire |

| 60000pcs/8h noodles production line For Sale South Africa |

| Small electric instant noodle production line for sale Lebanon |

| 60000pcs/8h instant noodle production line for sale UAE |

Packing

We can supply you the seasons bag packaging machinery. To loading spices powder and oil.

Packaging:

Inside: plastic bag.

Outside: wooden case (adopt the wooden case or wooden pellets depended on customers' requirement).

Shipping

One 20ft container or 40ft container

Our Service

| Service for Pre-sale | Service for After-sale |

| 1.Provide technical parameter 2.Factory layout and size suggestion 3.Provide general formulation 4.Custom-Design service 5.Professional Advice about Market, machines, materials, packing 6. Suggesting professional ship agent or helping book ship as customer request. 7. 24 hours online service. | 1.Allocation chart as the buyer's request will be supplied. 2.Operation manual will be supplied after shipment. 3.One year warranty, life time maintenance with cost price. 4.Free easy broken spare parts will be sent with container . 5.First installation can be done by engineer. 6.Training workers in customer's factory. |

Company Introduction

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001.

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, snack machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, instant noodle machinery, pasta machinery, etc. - food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions and better after-sales service.