How to use Frying System Line?

With the improvement of people's living standard, fried snacks are becoming more and more popular, and people pay more attention to health issues, so there are higher requirements for fried snacks. There are many different fried snacks, and the Frying System Line can fry different types of food, such as vegetables, deli food, meat, etc. So, how to use Frying System Line?

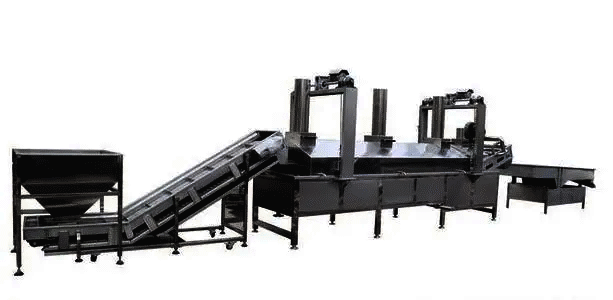

The operation of the Frying System Line is actually very simple. It consists of an automatic belt conveyor system, automatic lifting system, oiling system, oil filtering system, and automatic temperature control system. The assembly line design, the structure is reasonable, only one to two people can complete the entire operation, the degree of automation is very high. Let's take a look at its operation steps in detail.

The Fryer safety operation process mainly includes the preparation before starting the machine, the operation in the start-up state, and the cleaning after use. The specific steps are as follows:

First, the preparation before starting the machine

1, half an hour in advance to start the heat-conducting oil furnace.

2, turn on the main power switch of the fryer.

3, start the fryer rise button and check the mesh belt, bearings, and other rotating parts.

4, check whether there is debris or water inside each machine. If so, promptly clean up.

5, the correct installation of oil filter paper and adjust the position to ensure that the machine can operate normally.

6, check the peripheral piping and circulation system of the fryer, and press the button to reset the fryer if it is correct.

Second, start the machine

1, slowly add oil to the fryer until it is above the non-stick pan.

2, press the power distribution cabinet on the heating power control switch.

3, set the oil temperature parameters of the fryer according to production needs.

4, turn on the scraping control power and oil filtering, circulation pump system.

5, wait for the oil temperature to rise above 150 ℃ to start the mesh belt, non-stick pan, and oil replenishment power control.

6、Shut down the oil furnace heating system and cooling system ten minutes before the end of production.

Third, the cleaning steps after use

1、Ensure that all power has been turned off.

2, first, clean up the large residues, and then carefully check all parts that may be left with dirt, and carefully clean them up.

3, add clean water to the fryer, heat, and cook for about half an hour to drain off the sewage.

4、Use a high-pressure gun to clean the dirt in the fryer, carefully clean the oil pan, filter, rinse the inner and outer cover until clean.

5、Check all areas, check whether each part is clean, such as unclean re-cleaning.

6, after cleaning, close the drain valve, stop the mesh belt running, and turn off the main power supply.

The above is the operation process of the fryer. As long as you are using it with a little attention and follow the above methods correctly, you can basically complete the use of the fryer. In addition, the daily maintenance of frying equipment is also very important. Do a good job of frying machine maintenance work to extend the machine's life, save costs, and improve production efficiency. The following is an introduction to the maintenance of equipment.

Maintenance methods for frying equipment.

1, The equipment should be cleaned after each use. When cleaning, use a soft cloth soaked in neutral detergent to wipe gently. Do not use metal brushes, corrosive solvents, etc., so as not to damage the surface of the pot.

2、Every time the equipment is used, the use of various parts will become inflexible. You should regularly add lubricant to the equipment to ensure that the equipment can work smoothly.

3、Check the working condition of each part regularly to see if there is any failure in some places or aging of parts and solve any problems in time.

The above is the operation steps of the Frying System Line and daily maintenance methods. We should follow the correct method steps to operate when using and do a good job of daily maintenance of equipment to ensure the smooth production process, extend the service life of the equipment, and improve production efficiency.