Automatic Frequency Speed Controlling Sun Chips Production Line Extruder Machine

Fried chip snack food production line project using wheat flour, corn flour etc as raw materials, to make delicious different taste sun chips for sale. Loyal industrial fried pellet chips snacks machine all types of chips making machine engineering projects with great prices and high quality. We have exported to America, UK, Brazil, Thailand, Vietnam,an other 116 countries and regions. Automatic frequency speed controlling sun chips production line extruder machine can make different kinds fried snacks based on changing die molds and recipe, such as stick snacks ,bugles chips, Doritos chips, pellet chips and so on. The finished products are very crispy, delicious, and less oil. Fried chip snack food processing line like sun chips making machine has become the first choice for the manufacturer factory's hot-selling products.

Automatic Frequency Speed Controlling Sun Chips Production Line Extruder Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| MOQ | 1 set/ Sun Chips Production Line |

| Keywords | Fried Chip Snack Food Production Line |

| Certification | CE BV ISO 9001 |

| Voltage | 380V/50HZ Three Phase, 440v, 415v, etc |

| baking fuel | electric,gas,diesel,LPG |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Trial Demonstration | Welcome You To Visit Us At Any Time For Machinery Demonstration |

| Automation | Fully Automatic |

Automatic Frequency Speed Controlling Sun Chips Production Line Extruder Machine Detail Introduction :

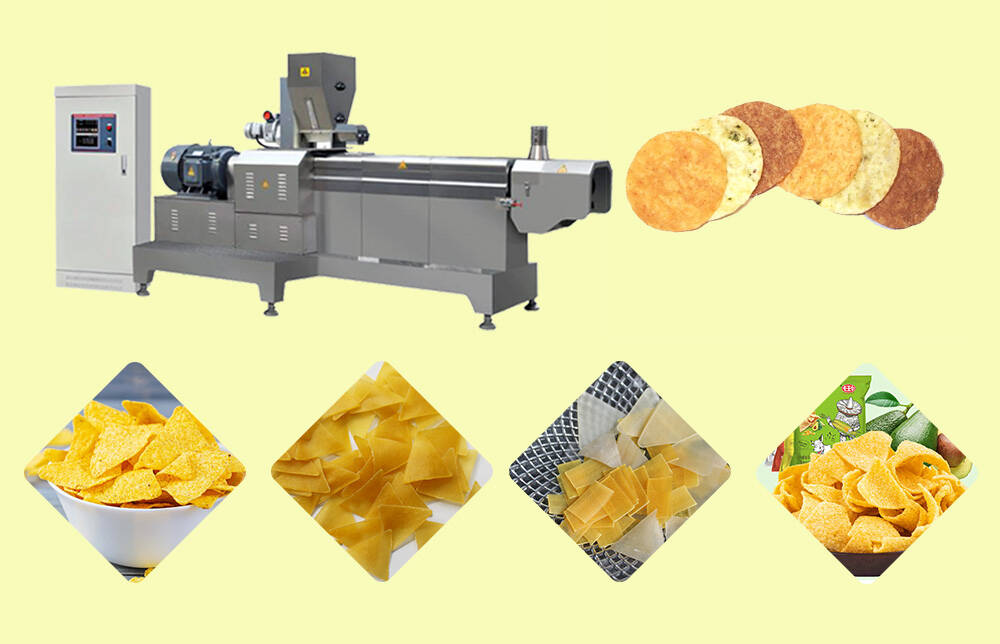

The Automatic Frequency Speed Controlling Sun Chips Production Line Extruder Machine is a specialized piece of equipment designed for the high-efficiency production of Sun Chips, a popular type of multigrain snack. This machine integrates advanced automation and frequency speed control technologies to streamline the entire manufacturing process of snack chips.

Sun Chips Production Line shall be apply to extruder ,the raw materials can be wheat flour,corn flour etc. Cutting by the multifunction shaper into various shapes, expanding by the fryer of fried snacks extrusion machine, and then seasoning. Sun chip snacks becomes the delicious snack food. This Frying Food Crisp Machines Potato Crisp Processing Line Salad Bugles Chips Food Making Machine Fried Rice Flakes Machine can make different kinds fried snacks based on changing die moulds and receipe. The finished products are very crispy, delicious, and less oil. Fried chip snack food processing line like sun chips making machine has become the first choice for the factory's hot-selling products.

SPECIFICATION OF HOT SALE SUN CHIPS PRODUCTION LINE:

The Brief Description Of The Automatic Sun Chips Production Line | |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Certification | CE,ISO9001,SGS,BV |

| Min.Order Quantity | 1 sets/Sun chips production line |

| Price | contact us |

| Output | 120-150kg/h, 200-250kg/h, 300-500kg/h , 800-1000kg/h |

| Material | 304 Stainless Steel |

| Feature | Automatic, Energy saving, High Productivity, Easy Operation |

| Heating Methods | Electric, Deisel, Gas power |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Delivery Time | 20days--35days |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days /potato chips making machine |

| Voltage | 380V |

| Dimension(L*W*H) | 7100X1100X1400mm |

| Weight | 850kg |

| Warranty | 1 YEAR |

| After-sales Service Provided | Video technical support, Engineers available to service machinery overseas |

| Application fields | Potato chips processing plant,supermarket,vegetables processing plant |

| Raw material | Fresh potato,cassava |

| Condition | New |

| Material | Stainless Steel 304 |

| Automatic | Automatic Sun chips making machine project |

| Function | Multifunctional |

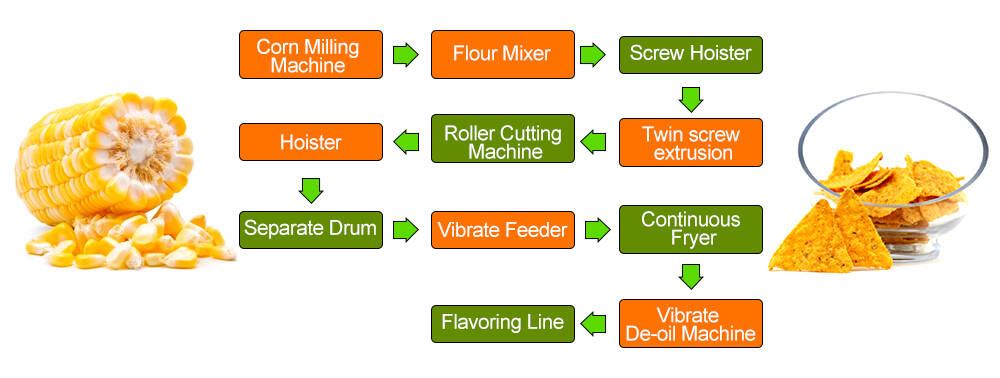

MANUFACTURING PROCESSES OF SUN CHIPS MULTIGRAIN SNACKS PROCESSION LINE:

Raw Material of Fried Snacks Chips Making Processing:

Corn flour, rice flour, wheat flour, startch,potato flour and other grain flour etc.

Technical Parameter Of Full Automatic Sun Chips Fried Snacks Production Line | |||||

| Model | Installed Power | Main Motor Power | Output | Size | Price($) |

| LY65 | 34kw | 22kw | 120-150kg/h | 3100*930*1850mm | 16,500-18,900 |

| LY70 | 53kw | 37kw | 200-250kg/h | 3200*760*2000mm | 22,500-26,500 |

| LY70L | 53kw | 37kw | 200-250kg/h | 3200*930*2000mm | 32,500-38,500 |

| LY85 | 99kw | 75kw | 500kg/h | 3800*1100*2350mm | 39,000-42,500 |

| LY100 | 101kw | 90kw | 800-1000kg/h | 5420*2300*2900mm | 44,500-47,000 |

The Sun Chips Production Line Price Is The Promote Price In 2022. Updated Price Pls Check With Our Chip Snacks Food Machine Line Team. | |||||

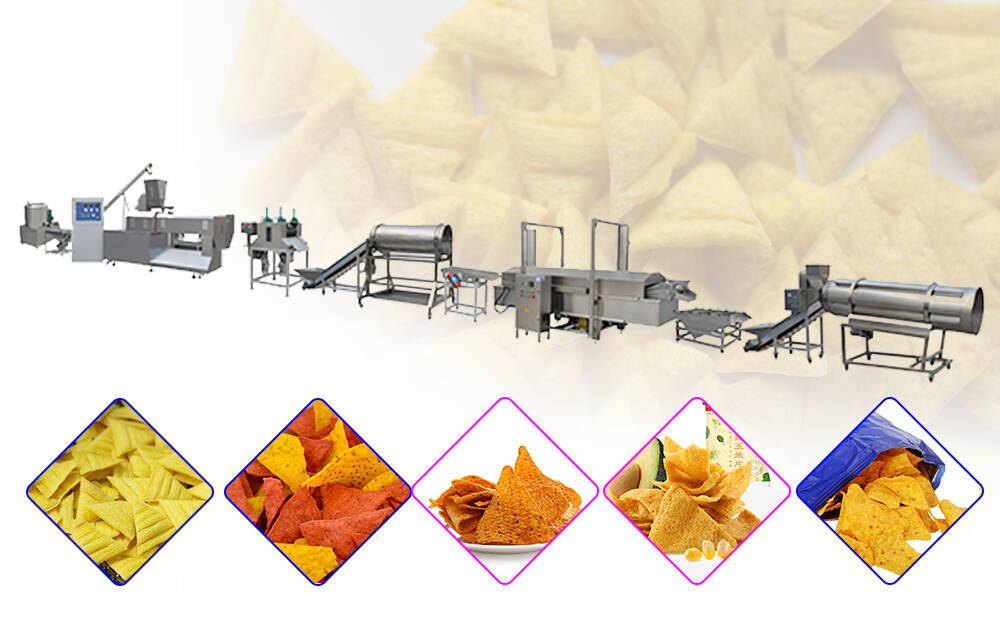

Fried Chip Snack Food Production Line Including:

Mixer--Screw Conveyor--Twin-screw Extruder--Cutter--Hoister--Continuous Fryer--Deoiling Machine--Flavoring Line

Equipment List Of The Industrial Fried Snacks Chips Production Line | |

| Equipment | Introduction of the sun chips production line |

| Mixing Machine | Mix flour and other water with a certain proportion to mix it evenly. . |

| Screw Hoister | Deliver the material powder to next device extruder |

| Double -Screw Extruder | Its the mainly part in dough extruder machine ,it including feeding system extrusion system ,rotary cutting system,heating system, transmission system.puffing&cooking the mixed material with the high temperature and high pressure,then push out extruder to different shape through the molds. |

| Pulling&Cutting Machine(Shaping Machine) | Cutting the material out from extruder to sticks shape. Shaping machine :shaping the material out from extruder to differernt shapes by printing rollers,such as triangles, small gourds, small fish, horns, etc. |

| Automatic Frying Machine(Continuous Frying Machine) | Frying the semi-finished snacks,to make it more delicious,longer storage time , and the color is more beautiful. Automatic frying machine and continuous frying machine can be selected. |

| Vibrate De-Oil Cooler | Remove extra oil by shifting ,in the mean time,cooling the snack to make it more crispy. |

| Seasoning Line | There are octagonal barrels, cylinders, lifting single drum and double drum seasoning lines, which are configured according to different output. |

| Cooling Conveyor | Cooling the finished snack chips to make it more crispy |

| Packing Machine | Packing the snacks into different packing style. |

WHY CHOOSE THE SUN CHIPS MULTIGRAIN SNACK MACHINE TO MAKE FRIED SNACKS?

1. The automatic control of oil temperature which can be set from 0-220ºC during the whole operation applies to frying the foods with various process requirements.

2. The filling valve is installed in the oil layer at bottom and the water can be added at any time without affecting the frying process. The equipment is also equipped with the check valve which can solve the problem that oil flows back to the water pipe in case of water supply is cut off.

3. The foods produced by the technology of this frying equipment have a better degree of finish with bright color.

4. Fully automatic, can save labor for manufacturer.

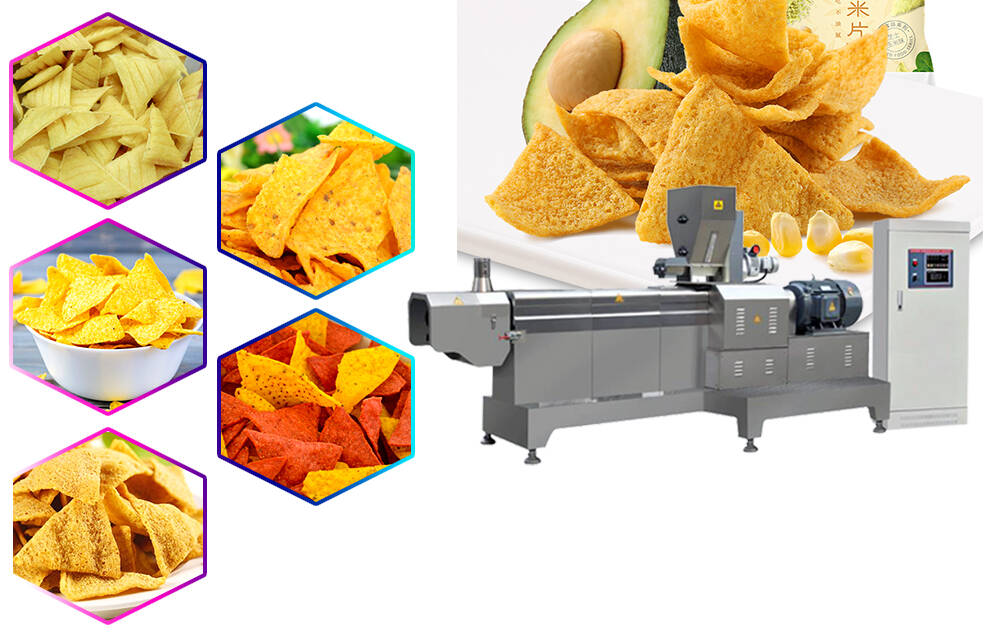

FINISHED SAMPLES PICTURES OF FRIED CHIP SUN CHIPS SNACK FOOD PROCESSING LINE

We can make many different kinds of shapes & tastes by changing molds.

Which Market Of The Fried Chips Snacks Food Production Line Has Been Loyal Sold In 2021 ?

Customer Case Of Muti-Function Fried Chips Production Line With Discount Price In 2021 | |

1 | 100-150/H 2D 3D Potato Snack Food Processing Line For Sale Senegal Suppliers Factory |

2 | 300kg/h Fried Bugles Chips Snack Food Processing Making Machine For Sale Nigeria |

3 | 100-150Kg/H Double Screw Fried Puff Bugle Chip Extruder Machine For Sale Burkina Faso Manufacturing Processing |

4 | 150Kg/H Automatic Corn Fried Chips Production Line For Sale Botswana Agent |

5 | 100-150kg/h Fried Snacks Chips Food Extruder Machine For Sale Philippines Customer Factory Plant |

6 | 800kg/h Automatic Corn Fried Sun Chips Machine For Sale Pakistan With Discount Price For Sale |

7 | 200-250 Kg/H automatic Fried Pellet Machine Processing Machine Line For Sale Mozambique |

High Quality Trader Customer Case Of The Industrial Fried Pellet Chips Snacks Food Equipment Processing Line Price In 2021 | |

1 | 100kg/h Puffed Snacks Flour Fried Salad Chips Food Maker Machine Production Line For Sale Bolivia Agent |

2 | 800kg/H Industrial Fried Triangle Chips Food Processing Equipment Cost Price For Sale Dominica |

3 | 300kg/h Fried Sticks Food Maker Machine Production Line In Senegal Manufacturers |

4 | 100-150Kg/H Fried Snacks Making Machine Crispy Chips Making Processing Machinery Price In Nigeria |

5 | 200-250kg/h Double Screw Bugle Chip Extruder Machine Factory For Sale Cote d'Ivoire |

6 | LY-65 Testing Machine For Corn Chips Food Making Machine Snack Machine Cost For Sale Cameroon |

7 | LY-70 Cone Shape Fried Sun Chips Machine Snacks Food Production Line For Sale South Africa Pet Food Suppliers |

Customer Case Of The Frying Snacks Food Pellet Chips Machine Equipment With The Farm Setting In 2021 | |

1 | 200-250kg/h Automatic Bugle Chips Frying Machine For Sale Thailand Agent |

2 | 100kg/h Industry Corn Chips Snack Extruding Machine For Sale (Tashkent) Agent |

3 | 500kg/H Fully Automatic Large Doritos Chips Machine For Sale America Manufacturers |

4 | 1000kg/H Automatic Fried Pellets Chips Cutting Snacks Food Machines For Brazil Suppliers |

WHY CHOOSE OUR FRIED SNACKS EXTRUSION MACHINE MULTIGRAIN SNACKS PRODUCTION LINE?

The Services Of Loyal Industrial Company | |

High-quality after-sales service | Engineer services for overseas machinery services |

1. The distribution map requested by the buyer will be provided. | 1. Provide free consultation service before, during and after sale. |

1.We are real facotry located at jinan, can provide you best cost price.

2.More than 15 years experience at the food machinery field. We pay more attention on each detials of the equipment,provide basic formula and 1 year warranty for the machines.

3.A sound management system that controls every aspect of machine production.

4.24 hours service One day.For any questions, professional technicians will solve for you timely. Training workers for the production,provide overseas installation and train the first-line operators.