Everything You Need to Know About White And Yellow Panko Bread Crumb Chips Food Extruder

Introduction to Panko Bread Crumb Extruders

Panko bread crumbs, known for their light and crispy texture, have become a staple in culinary applications worldwide. The production of these breadcrumbs has been revolutionized by advanced food machinery, particularly the White And Yellow Panko Bread Crumb Chips Food Extruder. This sophisticated equipment ensures uniformity and efficiency in the production process, making it an essential tool in the food industry.

The White And Yellow Panko Bread Crumb Chips Food Extruder operates by combining raw ingredients, processing them under high pressure and temperature, and then shaping them into the desired form. This process not only enhances the texture and appearance of the panko crumbs but also optimizes their moisture content for improved shelf life and usability.

Investing in a White And Yellow Panko Bread Crumb Chips Food Extruder can significantly streamline production lines, reduce labor costs, and enhance product quality. As more manufacturers adopt this technology, the consistency and availability of high-quality panko bread crumbs continue to improve, benefiting both producers and consumers.

Benefits of Using Food Extruders in Industry

One of the primary benefits of using a White And Yellow Panko Bread Crumb Chips Food Extruder in the food industry is its ability to produce uniform and high-quality products. The extrusion process ensures that each crumb is identical in size and texture, which is crucial for both aesthetic and functional purposes in culinary applications.

Another significant advantage is the efficiency and cost-effectiveness of the extrusion process. By integrating a White And Yellow Panko Bread Crumb Chips Food Extruder into the production line, manufacturers can drastically reduce manual labor and minimize production time. This leads to lower operational costs and higher output rates, making it a highly profitable investment.

Moreover, the versatility of the White And Yellow Panko Bread Crumb Chips Food Extruder allows manufacturers to experiment with different recipes and formulations. This flexibility is vital in an industry that constantly evolves with consumer preferences and market trends. Whether it's adjusting the texture or incorporating new flavors, the extruder provides the capability to innovate and meet diverse market demands.

Lastly, the extruder plays a pivotal role in enhancing food safety and hygiene. The closed system of the White And Yellow Panko Bread Crumb Chips Food Extruder minimizes the risk of contamination, ensuring that the final product meets stringent health and safety standards. This is particularly important in large-scale food production where maintaining consistent quality and safety is paramount.

Key Features of White and Yellow Panko Extruders

To better understand the capabilities of these extruders, we have compiled a detailed table highlighting their key features:

Feature | Description |

High Throughput | These extruders are designed to handle large volumes, ensuring continuous production to meet high demand. |

Precision Control | Advanced control systems allow precise adjustment of temperature, pressure, and extrusion speed, ensuring uniform quality of White And Yellow Panko Bread Crumb Chips. |

Versatility | Capable of producing both white and yellow panko breadcrumbs, these machines offer flexibility in product variety without requiring extensive reconfiguration. |

Energy Efficiency | Modern extruders incorporate energy-saving technologies, reducing operational costs and environmental impact. |

Durability | Built with high-quality materials and components, these extruders offer long service life and reliable performance even under continuous operation. |

Automated Cleaning Systems | Integrated cleaning mechanisms reduce downtime and labor costs, maintaining hygiene standards and ensuring the safety of the produced White And Yellow Panko Bread Crumb Chips. |

User-Friendly Interface | Intuitive control panels and software make operation simple and reduce the need for extensive operator training. |

Modular Design | Modular components facilitate easy maintenance and upgrades, enhancing the longevity and adaptability of the extruder. |

Quality Consistency | Ensures consistent texture and size of the breadcrumbs, which is crucial for maintaining product standards and customer satisfaction. |

How Food Extruders Improve Production Efficiency

Food extruders, particularly those used in producing White And Yellow Panko Bread Crumb Chips, significantly enhance production efficiency through various means:

Streamlined Production Process: Food extruders automate the production of breadcrumbs, reducing the need for manual intervention. This automation not only speeds up the production process but also minimizes human error, leading to a more consistent product quality. By maintaining precise control over the extrusion parameters, manufacturers can ensure that each batch of White And Yellow Panko Bread Crumb Chips meets the desired standards.

Resource Optimization: Modern food extruders are designed to be energy-efficient, utilizing advanced technologies that minimize energy consumption without compromising output. This results in lower operational costs and a reduced environmental footprint. Additionally, the precise control systems help in optimizing the use of raw materials, ensuring that there is minimal waste during production.

Reduced Downtime: Extruders equipped with automated cleaning systems and modular designs allow for quicker maintenance and less downtime. This continuous operation capability is crucial in maintaining high production rates. The ease of cleaning and maintenance not only extends the lifespan of the equipment but also ensures that the production of White And Yellow Panko Bread Crumb Chips remains uninterrupted.

Enhanced Product Quality: The consistency and precision provided by food extruders ensure that the quality of the White And Yellow Panko Bread Crumb Chips remains high across all batches. Advanced control systems allow for fine-tuning of the extrusion process, enabling the production of breadcrumbs with uniform texture and size. This uniformity is essential for meeting customer expectations and maintaining a competitive edge in the market.

Maintenance Tips for Panko Bread Crumb Extruders

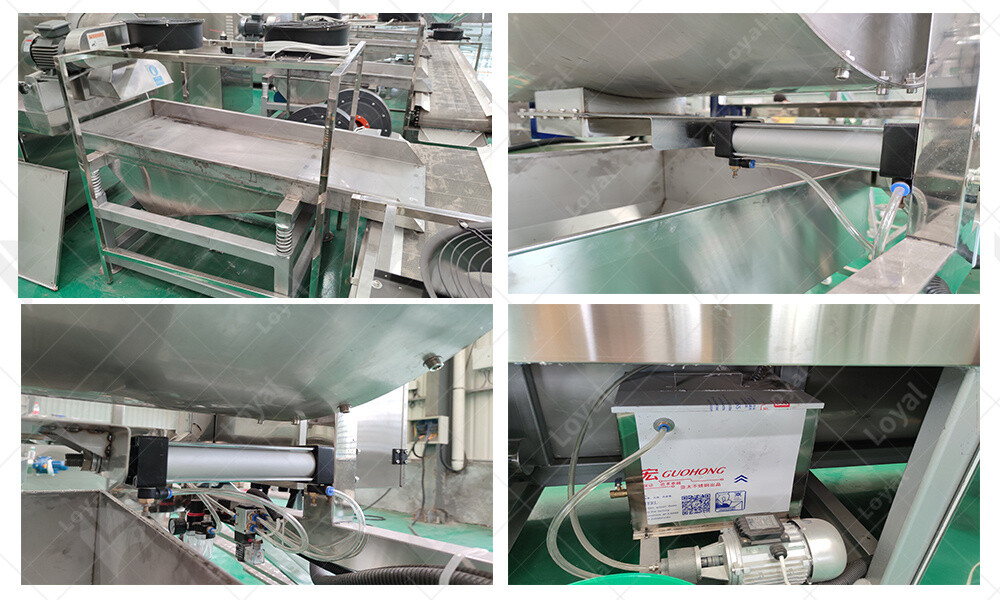

Proper maintenance of a White And Yellow Panko Bread Crumb Chips Food Extruder is essential to ensure efficient and long-term operation. Regularly inspect the extruder for any signs of wear and tear, especially focusing on the screw and barrel. These components are critical for maintaining the consistency and quality of the panko bread crumbs produced.

Lubrication is another key aspect of maintaining your White And Yellow Panko Bread Crumb Chips Food Extruder. Ensure that all moving parts are adequately lubricated to prevent friction and overheating. Use only manufacturer-recommended lubricants to avoid any potential contamination of the food product.

Cleaning the extruder thoroughly after each use is crucial to prevent residue buildup that could affect the quality of the bread crumbs. Pay particular attention to the die and cutting assembly. These areas are prone to clogging, which can impede the extrusion process and compromise the texture of the panko crumbs.

Lastly, schedule regular professional maintenance checks. Experienced technicians can identify potential issues before they become significant problems. This proactive approach ensures that your White And Yellow Panko Bread Crumb Chips Food Extruder operates at peak efficiency, reducing downtime and extending the equipment's lifespan.

Innovations in Food Extrusion Technology 2024

The year 2024 is set to witness remarkable innovations in the field of food extrusion technology, particularly for the White And Yellow Panko Bread Crumb Chips Food Extruder. One significant advancement is the integration of AI and machine learning to optimize the extrusion process. These technologies enable real-time adjustments, ensuring consistent quality and reducing waste.

Another groundbreaking development is the introduction of energy-efficient extruders. These new models are designed to minimize energy consumption while maximizing output, which is particularly beneficial for large-scale production of panko bread crumbs. The White And Yellow Panko Bread Crumb Chips Food Extruder will benefit greatly from these energy-saving features, making it more cost-effective and environmentally friendly.

The use of advanced materials in the construction of extruders is also on the rise. These materials enhance durability and reduce the need for frequent replacements. For instance, high-performance alloys and coatings are now being used to extend the lifespan of critical components such as screws and barrels in the White And Yellow Panko Bread Crumb Chips Food Extruder.

Finally, modular design is becoming a popular trend in food extrusion technology. This design approach allows for easy upgrades and customization of extruders to meet specific production needs. The White And Yellow Panko Bread Crumb Chips Food Extruder can be tailored to produce different textures and sizes of panko bread crumbs, providing manufacturers with greater flexibility and the ability to respond quickly to market demands.

Common Issues and Troubleshooting Extruders

In the production of White And Yellow Panko Bread Crumb Chips Food Extruder, several common issues may arise, affecting both efficiency and product quality. One frequent problem is inconsistent product size, often caused by wear and tear on the extruder die. To address this, regular maintenance and timely replacement of worn parts are essential.

Another issue is clogging, which can result from improper mixing of ingredients or inadequate pre-processing. Ensuring that all raw materials are thoroughly mixed and free from contaminants before entering the White And Yellow Panko Bread Crumb Chips Food Extruder can mitigate this problem. Regular cleaning of the extruder's internal components also helps prevent build-up that leads to clogging.

Temperature fluctuations within the extruder can lead to inconsistent texture and quality of the panko bread crumb chips. Monitoring the temperature closely and using advanced control systems can maintain a stable environment inside the White And Yellow Panko Bread Crumb Chips Food Extruder, ensuring uniform output.

Lastly, mechanical failures such as motor or gearbox breakdowns can halt production. Implementing a preventive maintenance schedule and conducting routine inspections can identify potential issues before they escalate, ensuring the White And Yellow Panko Bread Crumb Chips Food Extruder operates smoothly and efficiently.

Environmental Impact of Food Extruders

The environmental impact of food extruders, including those used for producing White And Yellow Panko Bread Crumb Chips Food Extruder, is a critical consideration for modern manufacturing practices. One significant impact is energy consumption. Extruders require substantial amounts of energy to operate at high temperatures and pressures. Utilizing energy-efficient technologies and optimizing operational settings can reduce the energy footprint of these machines.

Waste management is another environmental concern. The production process can generate waste materials, including excess crumbs and by-products. Implementing a recycling system within the White And Yellow Panko Bread Crumb Chips Food Extruder facility can help minimize waste, turning by-products into usable materials or energy sources.

Water usage in cleaning and cooling processes also contributes to the environmental footprint. Reducing water consumption through closed-loop systems and efficient cleaning protocols can significantly lower the environmental impact. Innovations in extruder design that minimize water requirements are also beneficial.

Finally, emissions from food extruder operations, such as those from fossil fuel-powered equipment, contribute to air pollution. Switching to renewable energy sources and employing advanced filtration systems can mitigate these emissions, making the production of White And Yellow Panko Bread Crumb Chips Food Extruder more environmentally friendly.

Cost Analysis and Budgeting for Extruders

When investing in a White And Yellow Panko Bread Crumb Chips Food Extruder, a thorough cost analysis is essential. The initial cost of purchasing the extruder is significant and varies depending on the model and capabilities. High-end models with advanced features can cost substantially more, but they often offer better efficiency and higher output rates, which can justify the initial investment over time.

Operating costs also play a crucial role in budgeting. This includes the cost of energy, maintenance, and raw materials. White And Yellow Panko Bread Crumb Chips Food Extruder machines are designed to be energy-efficient, but it's important to calculate the exact energy consumption and its impact on your operational budget. Additionally, regular maintenance is vital to ensure the longevity of the machine and prevent costly breakdowns.

Labor costs must be factored into the budget as well. While White And Yellow Panko Bread Crumb Chips Food Extruder machines are automated, skilled operators are still needed to oversee the process, troubleshoot issues, and ensure product quality. Investing in training for your staff can enhance efficiency and reduce long-term costs associated with errors and downtime.

Lastly, consider the cost of potential upgrades and expansions. As your business grows, you may need to scale up your operations. Investing in a White And Yellow Panko Bread Crumb Chips Food Extruder that offers modular upgrades can be a cost-effective solution, allowing you to expand capacity without a complete overhaul of your equipment.

Future Trends in Food Extrusion Technology

The food extrusion industry is rapidly evolving, with several emerging trends poised to shape the future. One notable trend is the increasing demand for healthier and more sustainable food products. White And Yellow Panko Bread Crumb Chips Food Extruder technology is adapting to this demand by enabling the production of low-fat, gluten-free, and organic breadcrumb chips, catering to a more health-conscious consumer base.

Automation and smart technology integration are also significant trends. Modern White And Yellow Panko Bread Crumb Chips Food Extruder machines are incorporating advanced sensors and AI to optimize the extrusion process. These technologies enhance precision, reduce waste, and improve overall product consistency. Predictive maintenance features are also becoming standard, minimizing downtime and extending the lifespan of the equipment.

Sustainability is another critical focus area. Extruder manufacturers are developing machines that are not only energy-efficient but also capable of utilizing alternative, eco-friendly raw materials. This shift towards sustainability aligns with global efforts to reduce the environmental impact of food production.

Lastly, the customization of extruded products is on the rise. Consumers are seeking unique textures and flavors, and White And Yellow Panko Bread Crumb Chips Food Extruder machines are being designed to offer greater flexibility in production. This allows manufacturers to experiment with different ingredients and formulations, meeting diverse consumer preferences and staying competitive in the market.

In conclusion, the future of food extrusion technology, especially concerning White And Yellow Panko Bread Crumb Chips Food Extruder, looks promising with advancements focusing on health, automation, sustainability, and customization. Keeping abreast of these trends will help manufacturers stay ahead in the competitive landscape.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com