Everything You Need to Know About Fully Automatic Biscuit Making Machine

Introduction to Fully Automatic Biscuit Making Machine

The biscuit manufacturing machine is a cornerstone of modern food processing technology. These machines are designed to streamline the production process, ensuring consistent quality and efficiency. A fully automatic biscuit making machine integrates various stages of biscuit production, from dough mixing to baking and cooling, into a single, seamless operation. This automation not only reduces the need for manual labor but also minimizes human error, leading to a more uniform product.

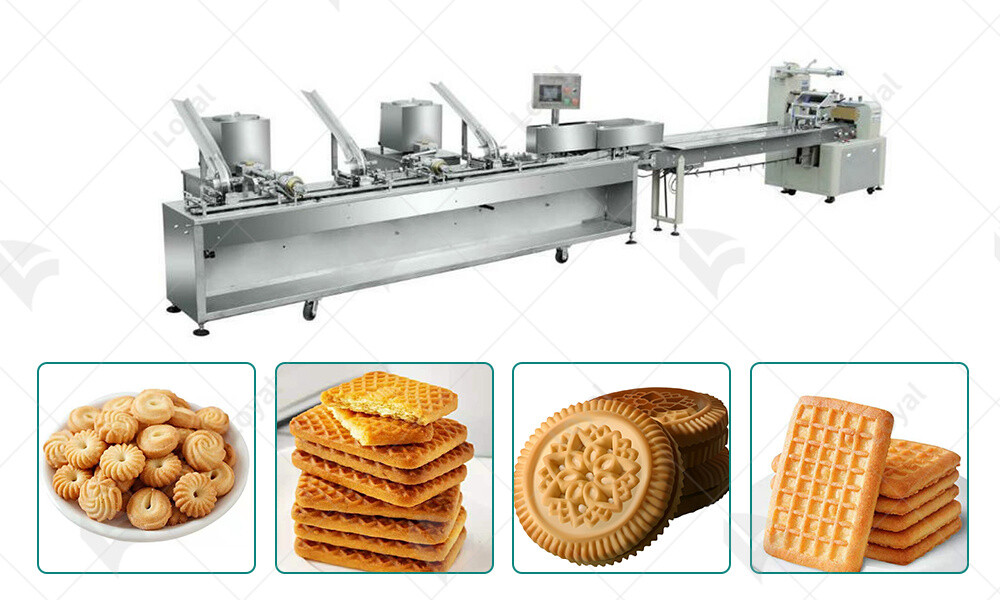

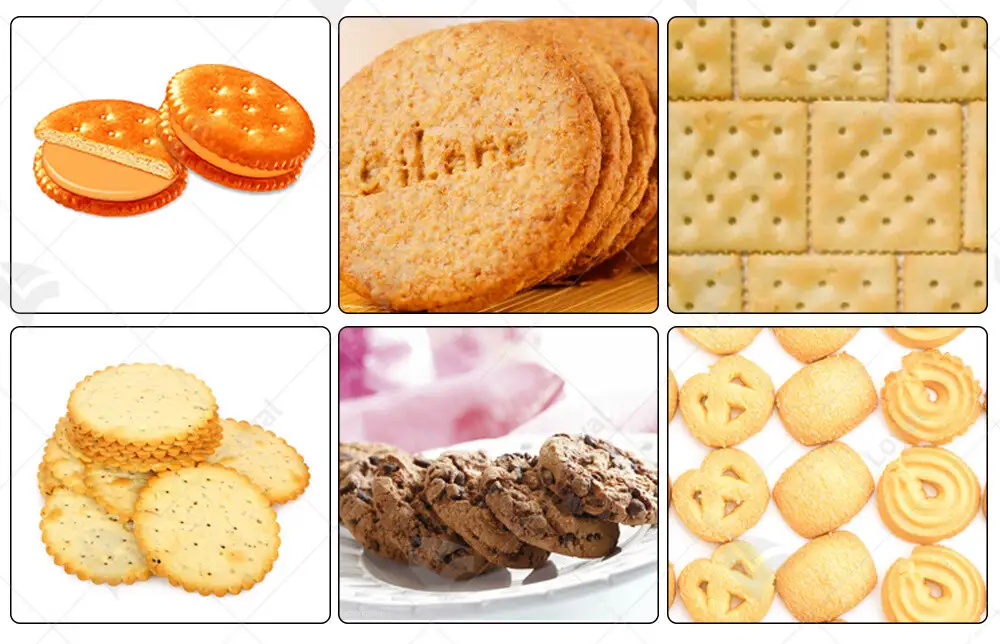

Fully automatic biscuit machines are equipped with advanced technology to handle different types of dough and create various biscuit shapes and sizes. This versatility makes them ideal for large-scale production in commercial settings, where high volume and consistent quality are paramount. With the increasing demand for biscuits worldwide, investing in a fully automatic biscuit making machine can significantly enhance a manufacturer’s productivity and profitability.

Key Features of Biscuit Making Machines

Feature | Description |

| Automation Level | Fully automated systems reduce manual intervention, ensuring consistent production and quality. |

| Versatility | Capable of producing a wide range of biscuit types, shapes, and sizes to meet diverse market needs. |

| Dough Handling | Advanced dough mixing and handling mechanisms for uniform dough consistency and quality. |

| Precision Baking | High-precision baking ovens with adjustable temperature controls for perfect baking results. |

| Cooling System | Efficient cooling systems to ensure biscuits are properly cooled and ready for packaging. |

| Production Speed | High-speed production capabilities to meet large-scale manufacturing demands. |

| Hygienic Design | Made from food-grade materials with easy-to-clean components, ensuring sanitary operations. |

| Energy Efficiency | Designed to optimize energy use, reducing operational costs and environmental impact. |

| User-Friendly Interface | Intuitive control panels with touch screens for easy operation and monitoring. |

| Quality Control | Integrated quality control systems to detect and correct defects during the production process. |

How Fully Automatic Biscuit Machines Work

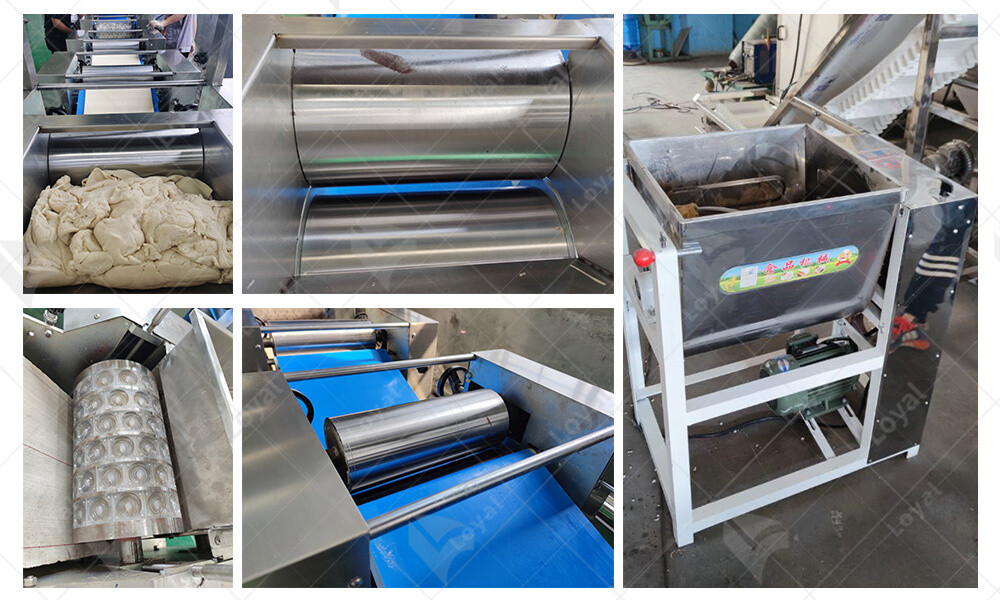

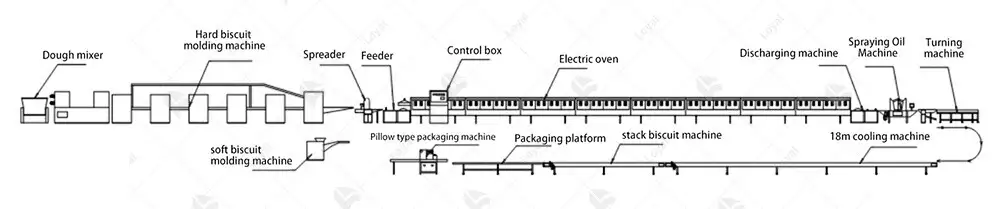

Fully automatic biscuit manufacturing machines operate through a well-coordinated series of processes. Initially, the ingredients are mixed in precise proportions in the dough mixer. This ensures that the dough has the right consistency and texture, which is crucial for producing high-quality biscuits. The automated mixer is designed to handle large volumes of ingredients efficiently, reducing preparation time and ensuring uniformity.

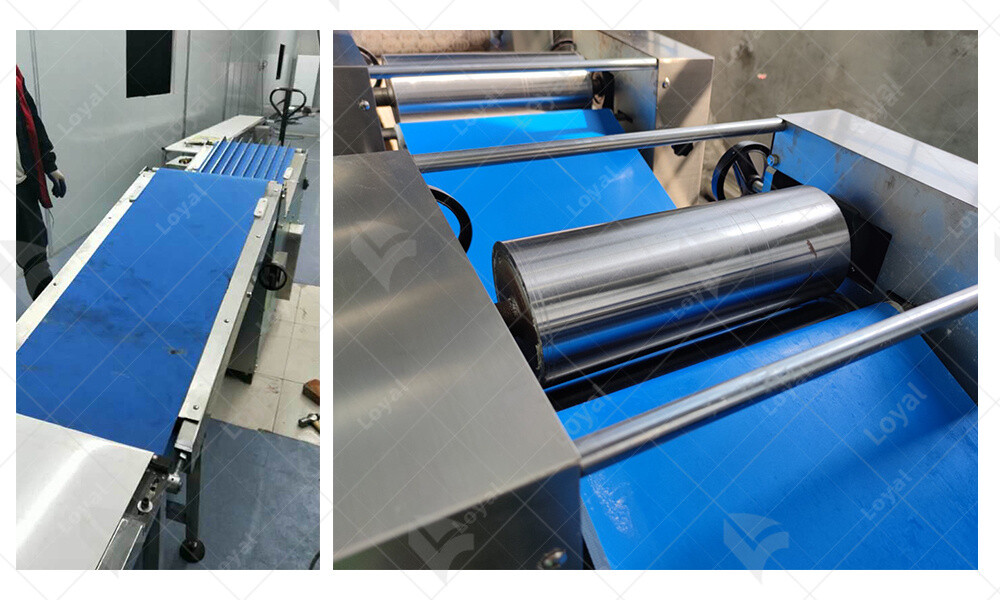

Once the dough is prepared, it is transferred to the forming section of the machine. Here, the dough is rolled, cut, and shaped into the desired forms using different molds and cutters. This section is highly versatile, allowing manufacturers to produce a wide variety of biscuit shapes and sizes. The precision of this stage ensures that each biscuit is uniform, which is essential for consistent baking and final product quality.

The shaped dough pieces are then conveyed into the baking oven. The ovens in fully automatic biscuit making machines are equipped with adjustable temperature controls and timers to ensure optimal baking conditions for different types of biscuits. After baking, the biscuits are passed through a cooling system to bring them to the right temperature for packaging. This cooling process is crucial as it prevents the biscuits from becoming soggy or losing their shape during packaging.

Advantages of Fully Automatic Biscuit Machines

Increased Production Efficiency: One of the primary advantages of fully automatic biscuit machines is their ability to significantly boost production efficiency. Through precise automation of various processes such as dough mixing, shaping, baking, and packaging, these machines can churn out large volumes of biscuits in a fraction of the time it would take with manual labor.

Consistent Quality: Maintaining consistent product quality is paramount in the food industry. Fully automatic biscuit machines excel in this aspect by ensuring uniformity in size, shape, texture, and taste of the biscuits. This consistency not only enhances consumer satisfaction but also strengthens brand reputation.

Cost Savings: While the initial investment in a fully automatic biscuit machine may be substantial, the long-term cost savings are considerable. By reducing the need for manual labor and minimizing ingredient wastage through precise control mechanisms, these machines offer a compelling return on investment over time.

Flexibility and Customization: Despite their high level of automation, modern fully automatic biscuit machines are equipped with advanced programming options that allow for flexibility and customization. Operators can easily adjust parameters such as baking time, temperature, and ingredient ratios to accommodate different recipes and product variations.

Hygiene and Food Safety: Maintaining strict hygiene standards is essential in food processing. Fully automatic biscuit machines are designed with hygiene in mind, featuring stainless steel construction and sanitary design elements that facilitate thorough cleaning and sanitation procedures. Additionally, automated processes minimize the risk of contamination associated with manual handling.

Types of Biscuit Making Machines

When it comes to biscuit manufacturing, various types of machines cater to different production needs. Below is a comprehensive breakdown of the types of biscuit making machines:

| Type | Description |

| Dough Mixer | A crucial component in biscuit production, the dough mixer blends ingredients uniformly to form a consistent dough. It ensures the homogeneity of the mixture, which is vital for the subsequent stages of biscuit making. LSI: dough mixing equipment, dough blending machine |

| Dough Sheeter | This machine is responsible for rolling out the dough to the desired thickness. It produces sheets of dough with precise thickness, ready for the cutting process. LSI: dough rolling machine, pastry sheeter |

| Biscuit Forming Machine | The biscuit forming machine shapes the dough into distinct biscuit forms. It employs molds or dies to create various shapes and designs as per the specifications. LSI: biscuit molding equipment, cookie forming machine |

| Baking Oven | Once the biscuits are formed, they pass through the baking oven, where they undergo controlled heat treatment. This stage imparts the characteristic texture and flavor to the biscuits. LSI: biscuit baking oven, cookie baking equipment |

| Cooling Conveyor | After baking, the biscuits need to cool down before packaging. The cooling conveyor facilitates this process by providing a controlled environment for the biscuits to reach ambient temperature. LSI: biscuit cooling system, cookie cooling conveyor |

These machines operate seamlessly together, constituting a fully automatic biscuit making line capable of producing large volumes of biscuits with minimal human intervention.

Selecting the Right Biscuit Making Machine:

When investing in a biscuit making machine, several factors warrant consideration to ensure optimal performance and compatibility with production requirements. Below is a comprehensive guide for selecting the right machine:

| Criteria | Description |

| Production Capacity | Production capacity serves as a fundamental criterion, dictating the volume of biscuits the machine can yield within a specified timeframe. Consider both current needs and future scalability. |

| Automation Level | Automation level varies among biscuit making machines, ranging from semi-automatic to fully automatic systems. Fully automatic machines streamline production processes, enhancing efficiency and reducing labor dependency. |

| Flexibility and Versatility | Flexibility and versatility pertain to the machine's ability to accommodate diverse biscuit types, shapes, and sizes. Opt for machines with adjustable settings to cater to evolving consumer preferences and market demands. |

| Quality of Biscuits | Biscuit quality hinges on factors such as dough consistency, baking precision, and uniformity in shape and texture. Prioritize machines renowned for producing high-quality biscuits that align with consumer expectations. |

| Reliability and Durability | Reliability and durability are paramount for uninterrupted production cycles. Choose machines crafted from robust materials and backed by reputable manufacturers to mitigate the risk of breakdowns and downtime. |

| Maintenance Requirements | Maintenance requirements encompass routine upkeep tasks, such as cleaning, lubrication, and parts replacement. Opt for machines with user-friendly maintenance protocols and accessible spare parts to minimize operational disruptions. |

Maintenance Tips for Biscuit Machines:

Proper maintenance is imperative to prolong the lifespan and ensure the optimal functionality of biscuit making machines. Here are essential maintenance tips to uphold:

Regular Cleaning and Sanitization: Cleaning and sanitization are vital to prevent bacterial contamination and maintain hygiene standards. Develop a routine cleaning schedule, focusing on areas prone to dough buildup, such as conveyor belts, hoppers, and nozzles.

Lubrication of Moving Parts: Lubricating moving parts mitigates friction and wear, preserving the machine's efficiency and extending its service life. Refer to the manufacturer's guidelines for recommended lubricants and lubrication intervals, adhering strictly to prescribed protocols.

Inspection of Wear and Tear: Conduct regular inspections to identify signs of wear and tear, such as worn-out conveyor belts, damaged seals, or malfunctioning sensors. Promptly address any issues by replacing worn components or scheduling repairs to prevent operational disruptions.

Training for Operators: Provide comprehensive training for machine operators to foster proficiency in operation, troubleshooting, and basic maintenance tasks. Empower operators to identify potential issues early on and execute remedial measures effectively to minimize downtime.

Stocking Essential Spare Parts: Maintain an inventory of essential spare parts, including belts, bearings, and sensors, to address unforeseen breakdowns promptly. Collaborate closely with suppliers or manufacturers to procure genuine spare parts and minimize lead times for replacements.

By adhering to these maintenance tips and investing in the appropriate biscuit making machine, manufacturers can optimize production efficiency, uphold product quality standards, and ensure a competitive edge in the dynamic landscape of the food industry.

Common Issues and Troubleshooting

When operating a biscuit manufacturing machine, several common issues can arise. One frequent problem is the inconsistency in biscuit thickness. This can be caused by uneven dough feeding or improper roller adjustments. Regularly inspecting and calibrating the rollers can help maintain uniform thickness.

Another issue often encountered is dough sticking to the conveyor or rollers. This can disrupt production and lead to wasted materials. Ensuring that the dough recipe has the correct moisture content and that the machine surfaces are properly lubricated can mitigate this problem.

Machine downtime due to mechanical failures is another common issue. Components such as belts, gears, and motors are subject to wear and tear. Implementing a preventive maintenance schedule and keeping spare parts on hand can reduce downtime and keep the biscuit manufacturing machine running smoothly.

Lastly, product contamination is a critical concern in food manufacturing. Regular cleaning and sanitation of the machine are essential to prevent contamination. Following strict hygiene protocols and using food-grade lubricants and materials can help ensure the safety and quality of the biscuits.

Enhancing Efficiency with Biscuit Machines

Maximizing the efficiency of a biscuit manufacturing machine involves several strategies. First, automating as many processes as possible can significantly increase production rates. Fully automatic systems that handle mixing, shaping, baking, and packaging can streamline operations and reduce labor costs.

Optimizing the workflow layout is also crucial. Placing machines in a logical sequence that minimizes the movement of materials can enhance efficiency. For instance, positioning the oven close to the shaping machine reduces the time and energy spent on transferring dough.

Using advanced monitoring and control systems can further enhance efficiency. These systems can track various parameters such as temperature, humidity, and production speed, allowing for real-time adjustments. This ensures consistent product quality and reduces waste.

Finally, training staff to properly operate and maintain the biscuit manufacturing machine is essential. Well-trained operators can quickly identify and resolve issues, minimizing downtime and ensuring the machine operates at peak efficiency.

Innovations in Biscuit Making Technology

The field of biscuit manufacturing machines is continuously evolving with technological advancements. One significant innovation is the development of energy-efficient ovens. These ovens use advanced heating elements and insulation materials to reduce energy consumption while maintaining optimal baking conditions.

Another breakthrough is the integration of IoT (Internet of Things) technology into biscuit machines. IoT-enabled machines can collect and analyze data in real-time, providing insights into production processes and machine performance. This allows for predictive maintenance and continuous improvement in efficiency.

3D printing technology has also made its way into biscuit manufacturing. Custom molds and intricate biscuit designs can be created using 3D printers, offering greater flexibility and creativity in product development. This technology enables manufacturers to quickly adapt to market trends and consumer preferences.

In conclusion, the advancements in biscuit manufacturing machines are transforming the industry. Energy-efficient ovens, IoT integration, and 3D printing are just a few examples of how technology is enhancing productivity, reducing costs, and enabling innovation in biscuit production.

Future Trends in Biscuit Manufacturing

The biscuit manufacturing machine industry is rapidly evolving, driven by advancements in technology and changing consumer preferences. One significant trend is the integration of artificial intelligence (AI) and machine learning into biscuit production lines. These technologies enhance efficiency by optimizing the production process, reducing waste, and ensuring consistent quality. AI-powered biscuit manufacturing machines can analyze data in real-time, making adjustments to temperature, mixing times, and ingredient ratios to produce the perfect batch every time.

Another trend shaping the future of biscuit manufacturing is the push towards sustainability. Manufacturers are increasingly adopting eco-friendly materials and processes to reduce their environmental footprint. This includes the use of energy-efficient biscuit manufacturing machines, which not only lower energy consumption but also support the use of biodegradable packaging materials. Additionally, there is a growing focus on reducing food waste through more precise ingredient handling and improved storage solutions.

The rise of personalized nutrition is also influencing the biscuit manufacturing machine market. Consumers are demanding more variety and customization in their food products, leading to the development of flexible manufacturing systems. These advanced machines can easily switch between different recipes and production methods, allowing manufacturers to cater to niche markets and dietary requirements. As a result, the future of biscuit manufacturing will likely see more diverse product offerings, tailored to individual health needs and taste preferences.

References

1.Baker Perkins - www.bakerperkins.com

2.GEA Group - www.gea.com

3.Bühler Group - www.buhlergroup.com

4.Reading Bakery Systems - www.readingbakery.com

5.Haas-Meincke (part of Bühler Group) - www.haas.com