Elevating Sterilization Standards: Full Automation and High Efficiency in Microwave Sterilization Equipment

Introduction

Our company leverages cutting-edge technologies from Cellencor and IMS to develop a state-of-the-art microwave sterilization technique. By drawing inspiration from the advanced methodologies employed by Cellencor and IMS, we have successfully integrated their innovative approaches into our manufacturing process. This collaborative effort ensures that our microwave sterilization technology meets the highest industry standards, providing an effective and efficient solution for eliminating harmful microorganisms. Through continuous refinement and adaptation of these proven techniques, our company remains at the forefront of technological advancements in the field, delivering products that prioritize both safety and quality.

Overview of Sterilization Challenges

Sterilizing food products has long been a challenge in the food industry. Conventional methods often fall short in terms of precision, speed, and environmental impact. Contamination risks and the need for enhanced efficiency have paved the way for technological advancements in the field of food sterilization.

Importance of Advanced Sterilization Technologies

The global food industry recognizes the paramount importance of adopting advanced sterilization technologies to meet evolving consumer expectations and regulatory standards. Microwave Sterilization Equipment emerges as a cutting-edge solution, offering a paradigm shift in how we approach food safety and quality.

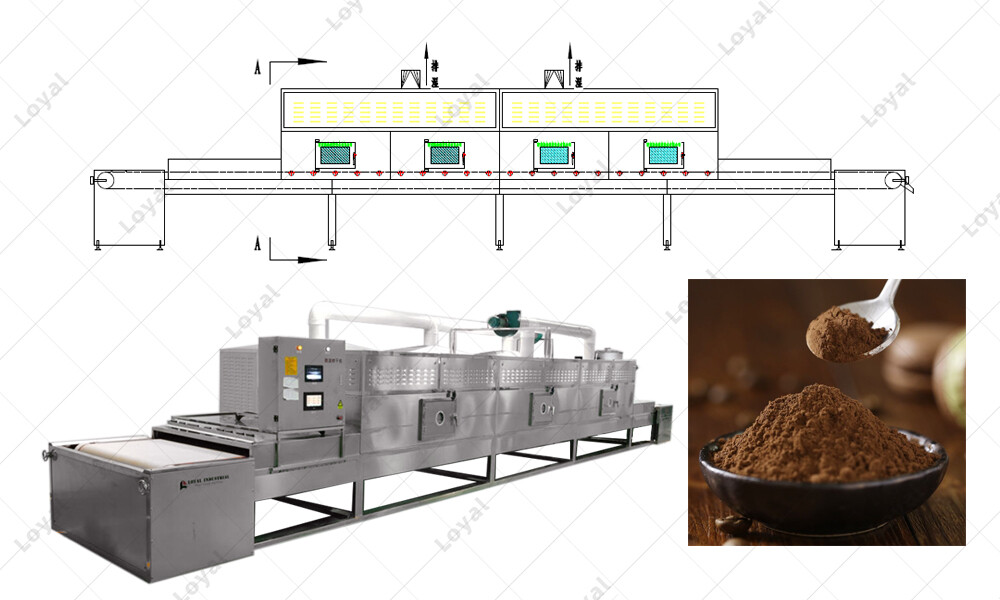

Transition to Microwave Sterilization Equipment

With a focus on elevating sterilization standards, the transition to Microwave Sterilization Equipment signifies a breakthrough. The following sections will explore the features, benefits, and real-world applications of this innovative technology.

Full Automation in Microwave Sterilization Equipment

Full Automation is a key aspect that distinguishes Microwave Sterilization Equipment from traditional methods. The incorporation of automated processes not only streamlines operations but also enhances precision and reliability.

Microwave Sterilization Equipment, with its Full Automation capabilities, integrates smart systems for seamless operation. Automated loading, unloading, and monitoring processes ensure consistency in sterilization, reducing the likelihood of human error.

The benefits of Full Automation extend beyond operational efficiency. It improves overall product quality by maintaining optimal sterilization conditions consistently. The reduction in manual intervention minimizes the risk of contamination and ensures compliance with stringent industry standards.

A comparative analysis will highlight the superiority of Microwave Sterilization Equipment over traditional methods. The speed, precision, and resource efficiency achieved through Full Automation set a new benchmark in the field of food sterilization.

High Efficiency for Enhanced Sterilization

High efficiency is a defining characteristic of Microwave Sterilization Equipment, revolutionizing the speed and precision at which sterilization is achieved.

This section will delve into the technological components contributing to the high efficiency of Microwave Sterilization Equipment. From advanced heating mechanisms to real-time monitoring, each element plays a crucial role in elevating the overall efficiency of the sterilization process.

Microwave Sterilization Equipment's high efficiency directly translates into accelerated sterilization processes without compromising precision. The article will provide insights into how this technology achieves both speed and accuracy, crucial factors in the food industry.

Real-world case studies will be presented to illustrate the tangible efficiency gains witnessed by industries adopting Microwave Sterilization Equipment. These examples will showcase the technology's practical application and its transformative impact on various sectors.

Stay tuned for the next installment, where we explore the technological advancements shaping the landscape of Microwave Sterilization Equipment.

Technological Advancements

Microwave Sterilization Equipment leverages state-of-the-art technologies to enhance its capabilities. This segment will delve into the specifics of these technologies, such as frequency modulation, adaptive control systems, and other innovations contributing to the equipment's efficiency and reliability.

The incorporation of smart systems sets Microwave Sterilization Equipment apart. From IoT-enabled monitoring to adaptive learning algorithms, these smart features optimize performance, ensuring precise sterilization tailored to specific food products.

Anticipating the future is crucial in the rapidly advancing field of sterilization. This part of the article will explore emerging trends and innovations, providing insights into what the future holds for Microwave Sterilization Equipment. Expert opinions and industry forecasts will be cited to lend authority to the discussion.

Applications and Industries

The versatility of Microwave Sterilization Equipment extends across various applications and industries. This section will shed light on the diverse applications of the technology, showcasing its adaptability and impact on different sectors.

Microwave Sterilization Equipment is not limited to a single application. This part will explore how this technology is employed in sterilizing a wide range of food products, including liquids, solids, and semi-liquids.

Different industries stand to gain significantly from the integration of Full Automation and High Efficiency in Microwave Sterilization. Case studies and testimonials from relevant industries will be presented to validate the positive impact of this technology on their processes.

This section will highlight real-world examples where Microwave Sterilization Equipment has been successfully implemented. These examples will serve as a testament to the practical advantages and positive outcomes experienced by companies embracing this innovative sterilization solution.

Stay tuned for the subsequent sections, where we delve into the environmental impact and energy efficiency of Microwave Sterilization Equipment, along with addressing challenges and providing solutions in the field.

Environmental Impact and Energy Efficiency

Considering the ecological footprint is paramount in modern industrial practices. This part of the article will focus on the environmental impact and energy efficiency aspects of Microwave Sterilization Equipment.

Microwave Sterilization Equipment's eco-friendly features will be discussed, emphasizing its role in minimizing environmental impact. From reduced water usage to lower energy consumption, the article will elucidate how this technology aligns with sustainable and green practices.

Delving deeper into the energy efficiency measures implemented in Microwave Sterilization Equipment, this section will explain how the technology optimizes energy use. Insights into sustainable practices, such as using renewable energy sources, will be explored to highlight the equipment's commitment to environmental responsibility.

A comparative analysis will be conducted to juxtapose the environmental impact of Microwave Sterilization Equipment with traditional sterilization methods. Scientific data and authoritative opinions will be referenced to provide a comprehensive understanding of the technology's ecological advantages.

Challenges and Solutions

Even with advanced technologies, challenges are inevitable. This section will identify potential challenges in Microwave Sterilization and propose effective strategies and solutions for overcoming these hurdles.

Anticipating challenges, including technical limitations and regulatory considerations, is crucial. This part will provide an insightful examination of the potential obstacles faced when implementing Microwave Sterilization Equipment.

To maintain a balanced perspective, viable strategies and solutions will be presented to address the identified challenges. Expert opinions and industry best practices will be incorporated to ensure the credibility and practicality of the proposed solutions.

Microwave Sterilization Equipment is not static; it undergoes continuous improvement. This segment will discuss how manufacturers actively engage in refining the design and functionality of the equipment to stay ahead of challenges and meet evolving industry demands.

The concluding sections will summarize the key advantages discussed throughout the article, provide a glimpse into the future outlook of Microwave Sterilization Equipment, and conclude with a compelling call to action for industry stakeholders. Stay tuned for the conclusion that encapsulates the essence of elevating sterilization standards through Full Automation and High Efficiency in Microwave Sterilization Equipment.