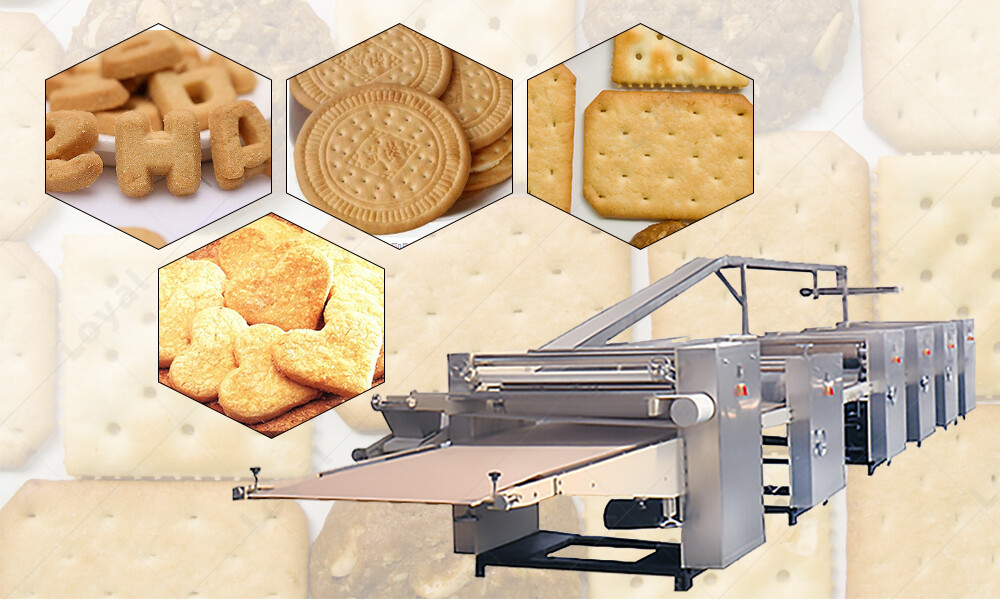

Biscuit Processing Line

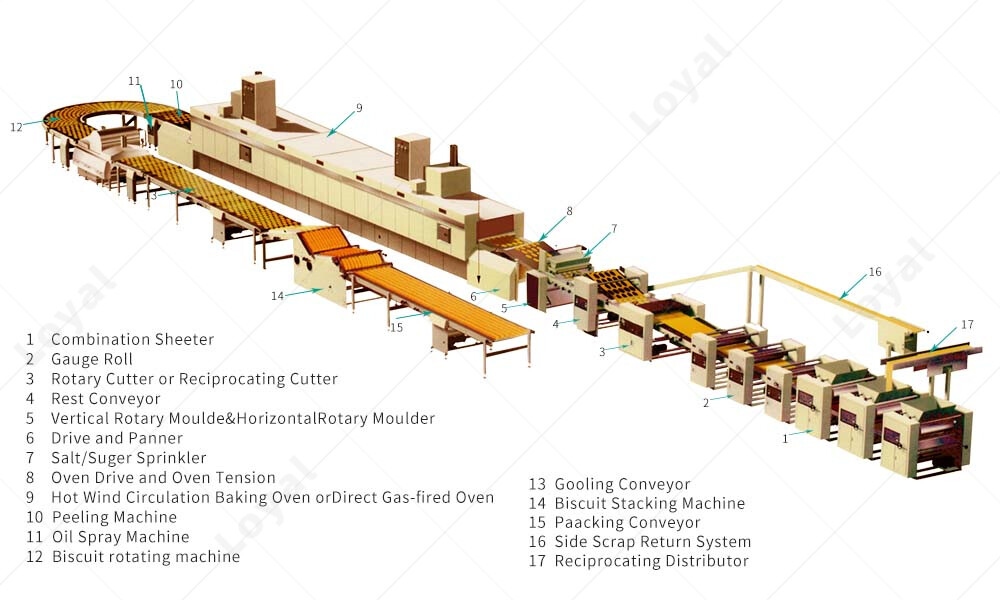

The biscuit processing line is a specialized system consisting of various machines and equipment for the production of biscuits and cookies. It involves several stages including dough preparation, shaping, baking, cooling, packing and sorting. The process begins by mixing together flour, sugar, fat, and other ingredients to create a dough. The dough is then passed through a set of rollers, which flatten it into a sheet. Next, the dough is passed through rotating molds, which shape it into the desired biscuit shape. After shaping, the biscuits are baked in an oven at a specific temperature and time. After baking, the biscuits are cooled on a conveyor belt or in a cooling room to achieve the desired texture and consistency. The final stage of the biscuit processing line involves packing and sorting. Biscuits are packed in boxes or bags and then sorted by size, shape and packaging. Automation of the sorting process helps save time and ensures packaging accuracy. Depending on production capacity and product type, biscuit processing lines can vary in size and complexity. It can be designed for small-scale or large-scale production, using different equipment and techniques to meet the required production needs.

The Flow Chart Of Biscuits Process Line

1.Flour mixer --- 2. Dough cutting machine --- 3. Dough conveyor --- 4. Hard biscuit forming machine --- 5. Soft biscuit forming machine --- 6. Inlet oven conveyor --- 7. Intelligent Temperature Control Tunnel Oven

The Function Of Biscuits Process Line

1.Mixing: The ingredients, including flour, sugar, butter, and other additives, are mixed together to form a dough.

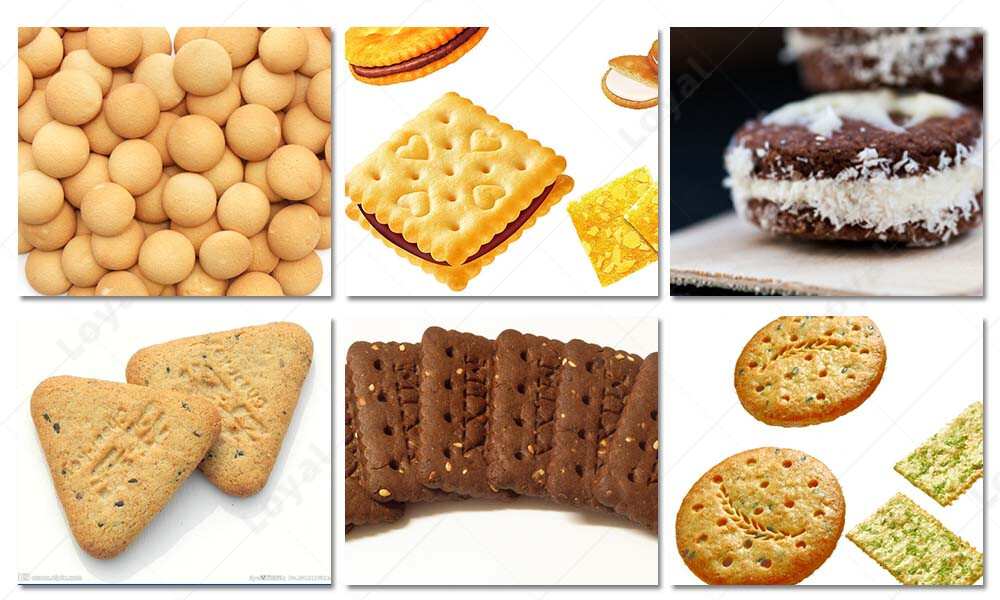

2.Forming: The dough is then shaped into a variety of shapes and sizes, depending on the type of biscuit being produced. This can be done by using a variety of machines, such as rollers, cutters, and extruders.

3.Baking: The biscuits are then baked in an oven at a specific temperature for a certain amount of time. The temperature and time will vary depending on the type of biscuit being produced.

4.Cooling: Once the biscuits are baked, they are cooled down to room temperature.

5.Packaging: The biscuits are then packaged in a variety of ways, such as in bags, boxes, or individual packets. The packaging may also include branding and labeling.

The Parameter Of Biscuits Process Line

Model | Capacity (kg/h) | Finished Biscuit |

LY-400 | 150-200kg/h | Soft biscuit,hard biscuit,sandwiching biscuit |

LY-600 | 400-500kg/h | Soft biscuit,hard biscuit,sandwiching biscuit |

LY-800 | 600-800kg/h | Soft biscuit,hard biscuit,sandwiching biscuit |

LY-1000 | 1000kg/h | Soft biscuit,hard biscuit,sandwiching biscuit |

We can design according to customer factory and required. | ||

The Advantage Of Biscuits Process Line

Increased Efficiency | A biscuits production line allows for a continuous and automated production process, reducing the need for manual labor and increasing the efficiency of the production process. |

Consistency In Quality | A biscuits production line ensures consistency in the quality of the biscuits produced, as the ingredients are measured and mixed accurately, and the baking process is controlled for consistent results. |

Cost-Effective | By automating the biscuits production process, a biscuits production line reduces labor costs and increases the production capacity, resulting in lower costs per unit produced. |

Higher Production Capacity | A biscuits production line can produce a large volume of biscuits in a shorter period, which can help meet demand during peak seasons or special events. |

Flexibility | Biscuits production lines can be adjusted to produce different types of biscuits with minimal downtime, allowing for greater flexibility in meeting changing consumer preferences or market demands. |

Hygiene | Biscuits production lines are designed with food safety and hygiene in mind, minimizing the risk of contamination and ensuring that the biscuits produced are safe for consumption. |