What is the corn flags manufacturing process?

The speed of life makes the public's time is greatly compressed. For many people, breakfast seems to have become a very extravagant thing. But don't eat breakfast, very harmful to the body. Long-term no breakfast The chances of gallstones will greatly increase. In which case the breakfast cereals have become the best choice.

The cornflake is a very popular breakfast cereal, which is very convenient and fast. Only need to use milk to be buddled, you can use it directly, it is very suitable for busy people. The market demand in corn flakes is very high, then do you understand what is the production process of cornflakes?

What is the corn flags manufacturing process?

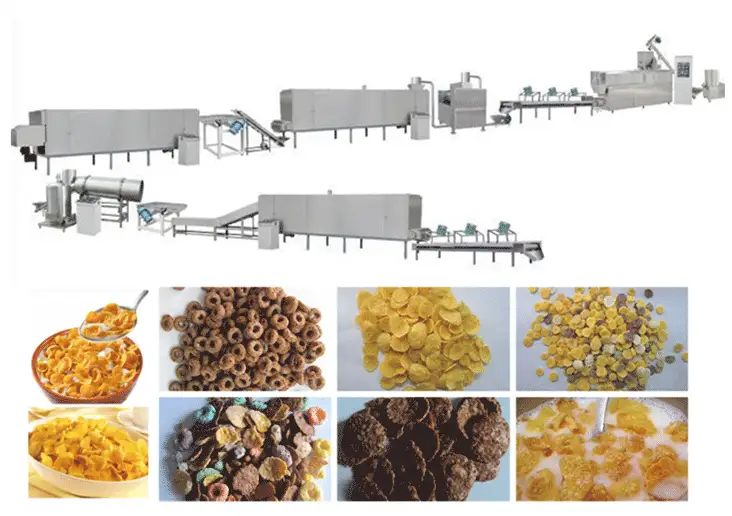

Cornflakes are the most common grain casual food in the world. It is the main raw material with corn. Then adds sugar, various vitamins, mineral mixed raw materials, mixed, squeezed, cut, pre-drying, tablets. High temperature Baking, seasoning and other production processes are made, usually with milk, well popular in the market.

The production process of corn flakes is more complicated. It is necessary to process production of various processes. First of all, the most important thing is the ratio of raw materials. Which has great relationship with the final taste of the cornflakes. A large part of the colorful cornfliches in the market is the use of high-quality formulations and high-quality raw materials. Which is the key to the expansion of the market.

The most important step after the completion of the raw material is to be extruded, in a state of high temperature and high pressure, the corn flake will be completely ripened without any puffing, only in this way can ensure that the produced corn slices feel crispy , Nutrients, therefore, the key to production is to use high quality extrusion equipment.

The squeezed corn flakes need to be cut, cutting it into particles uniform and uniform. So that the corn flakes produced will have higher quality. Drying is required after the cutting is completed, and the particles can be more convenient for subsequent processing production when the particles are in a dry state.

One of the very important steps is that the tablets are pressed, and the particles are pressed using a tablet machine, and the corn flakes are initially formed. Next, the corn flakes will be transported in a dryer, and the flavor of the corn flakes after dehydration is more highlighted, the aroma is rich, and the taste is crisp.

At this time, the cornflakes were produced. And this process was optional, sprinkled with salt, sugar or chocolate to the cornflakes, and modulated it into different tastes, and also received very many consumers. welcome.

The above is the production process of cornflakes. The most important thing is the application of extrusion technology. The technology is also the technology that produces the highest use rate of cornflakes. The produced corn flakes are popular with consumers, in similar goods It is always in the level of sales.

As a professional food machinery manufacturer, we have a very rich experience, which can provide the most advanced corn flake production process, which uses advanced extrusion technology, with fully automated production. Not only has very high production efficiency, but the produced cornflakes have very high quality.

corn flake production Line is low, the quality is reliable, the price is very high, you can use separate devices to use separate devices, use flexible use, is an ideal choice for manufacturers.

Today, the corn flake industry is very hot. If you want to improve your production process level, please feel free to contact us, I believe our cooperation must help you build a stable market network and achieve rapid increase in economic benefits!