What is the composition of automatic biscuit production line?

Introduction Of Automatic Biscuit Production Line:

The biscuit production line with different molds and different recipes can produce different shapes of biscuit, such as round and square, etc. It can also form different specifications of soft biscuit and hard biscuit through different recipes. The automatic production line is made by digesting and absorbing Japanese technology, with novel design and compact structure, high degree of automation, the whole process can be automated.

A flaky western-style snack made from flour as the main ingredient and baked. Biscuit are a common snack, as a snack or add to the diet, easy to eat and easy to carry, has become an indispensable food in daily life. Usually people love to choose biscuit as a snack because they are tasty and can replenish the energy needed by the body.

The Production Line Details:

| Capacity | 50-60KG/h; 150-200KG/h; 200-250KG/h; 400-500KG/h; 600-800KG/h; 1000KG/h; 2000KG/h |

| Electricity supply | Customized according to your local electricity situation. |

| Machine details | 1. Stainless steel,:201, 304, 316, on request. 2. Electrical components can be ABB, Delta, Fuji, Siemens; famous brands. |

| Certificates | CE,GOST,TUV,BV |

| Raw material | Wheat flour, Sugar, Eggs, Relaxing Agent, Milk Powder, etc. |

| Product colour | Brown, yellow, black, etc. |

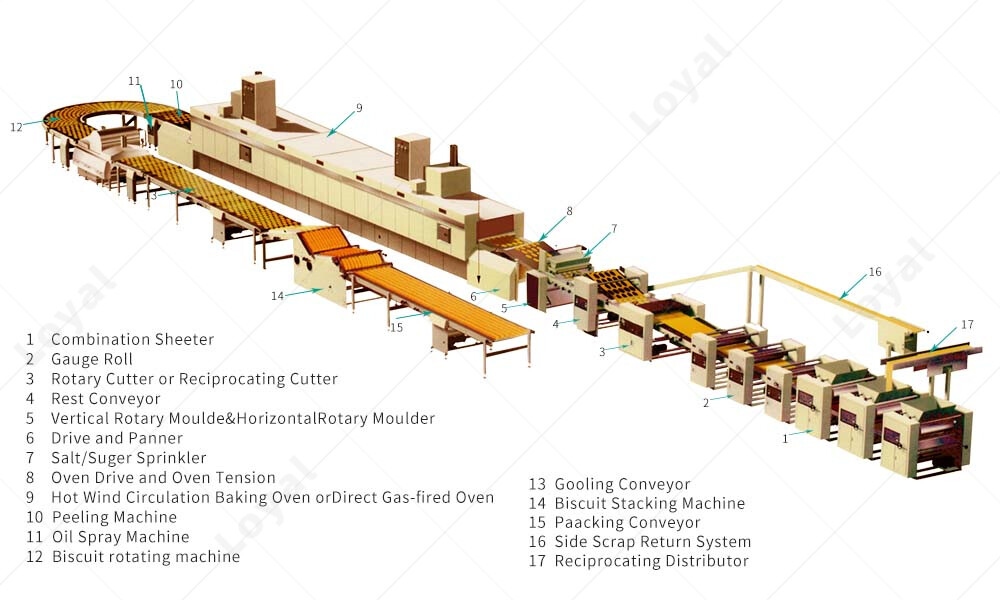

Flow Chart of Automatic Biscuit Production Line:

Mixing of flour, eggs, sugar and seasonings - -Dough mixing -- Biscuit forming (Rolling And Cutting) -- Oven baking-- Oil spraying--Cooling conveying- -Sorting- -Sandwiching--Packing.

Flow Chart Diagram:

Feature Of Automatic Biscuit Production Line:

1.High degree of automation: The bread crumb production line has a very high degree of automation, which can well meet the needs of customers and fully meet the needs of various enterprises.

2.Large output: It can realize multiple batch processing, thus avoiding problems such as equipment downtime and long downtime due to different batches. The output of the equipment is large, thus ensuring the production efficiency and quality. At the same time, the production speed of the equipment is fast, and the output can be adjusted at any time according to the output needs of different users.

3.Low energy consumption: It can effectively reduce the utilization rate of energy and achieve the purpose of saving costs.

4.Sanitation and cleaning: The equipment adopts a new type of dust removal equipment, which can well avoid dust pollution to the surrounding environment and ensure environmental hygiene. In the process of processing, a certain amount of dust will be generated. If the dust is not effectively removed, the dust will cause harm to the health of the workers.

5.Easy to operate: The device is easy to operate and easy to use, whether it is a small-scale enterprise or a large-scale enterprise, it can be easily used.

The above are the characteristics of the bread crumb production line. This equipment has the advantages of large output, high efficiency and low energy consumption, and can meet the needs of various customers.

Applications Of Automatic Biscuit Production Line:

The biscuit production line can only be used for biscuit food. The biscuit production line is different from other puffed food production lines. The steps in the biscuit production line are indispensable. The line is highly automated, and as the demand for biscuits continues to expand, so does the demand for biscuit production lines. The line can produce sandwich biscuits, soft biscuits, and hard biscuits. The specific catalog of biscuits that can be produced are as follows: cream biscuits, sandwich biscuits, millet biscuits, ultra-thin biscuits, calcium milk biscuits, chocolate biscuits, soda biscuits, animal biscuits, vegetable biscuits, etc.