What are the main components of organic feeds?

Feed is the general term of the food of animals raised by everyone. The narrow general feed mainly refers to the food of animals raised by agriculture or animal husbandry. There are many types of feeds. the organic feed is one of them. what is organic feed, What are the main components of organic feeds? How is the organic feed?

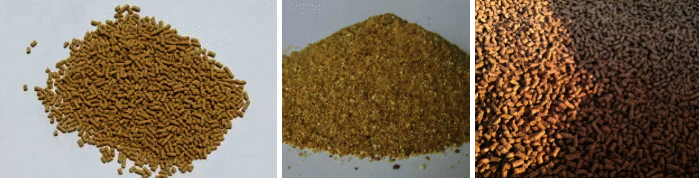

Feed includes more than 10 types of feed raw materials. Such as soybean, soybean meal, corn, fishmeal, amino acid, hybrid, whey powder, grease, meat powder, cereal, feed additives. In addition to minerals and water, others are basically organic. And organic feed products are produced by organic feed materials in accordance with organic feed materials in accordance with organic feed ratings by organic feeding materials.

Organic feed shall not use chemical synthetic drugs.Promote growth agents and other chemical synthetic additives in the product. And are not allowed to use the products obtained from genetic engineering techniques, such as transgenic soybean meal, cottonseed meal, etc. Product quality is inspected in line with organic feed standards Provisions and certified allows the use of organic products to be used on product packaging. The requirements of this type of product are higher than that of the green feed, and only the above conditions or the above-described feed can be referred to as organic feed, otherwise it is not an organic feed.

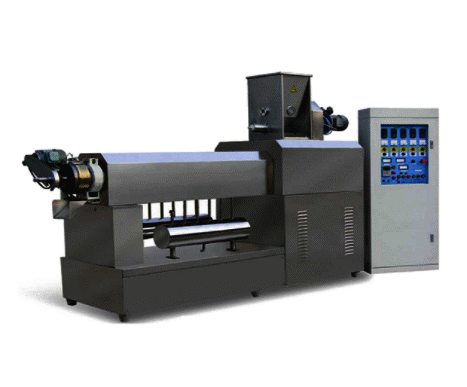

Feed Production Line is dedicated to equipment for making various feed, and also can also be used to produce organic feed. The feed granulator can be driven by electricity or diesel engine according to different situations, and can process different sizes of particles, widely used for poultry feeds such as chicken, duck, cattle, sheep, and other birds or fish feeds. Its cost is lower than other feed particles, simple operation, it has the following features:

Feed Production Line Features:

1, simple structure, wide adaptability, small area, low noise, high efficiency.

2, Reduce the model time of making different specifications products. Saving operational area, more convenient operation, cutting speed is adjusted by the inverter, facilitating control particle length.

3, powdered feed and grass powder can be added or small amounts of granulation. So the water content of the particulate feed is substantially the water content of the particulate material, more conservative.

4, the particle formation process can make the tricks in the grain and beans. Reduce the adverse effect on digestion. Kill various parasitic eggs and other pathogenic microorganisms, reduce various worms and digestive system diseases.

5, simple design, easy to operate. Can make various feeds. Only need to replace different molds, you can get different size, excellent taste, color seductive feed particles.

Feed production line materials:

Most feed particles include animal proteins and plant proteins. Plant proteins use corn flour, rice noodles, wheat flour, soy flour, peanut powder, etc. Animal protein, fish powder, shrimp powder, crab powder, sleeve powder, etc. Other ingredients can also be added according to the life of animals.

The main equipment configuration of the feed production line:

Crusher → Mixer → Conveyor → Extruder → Elevator → Dryer → Cooling Machine → Vibration Screen → Elevator → Injection Machine → Automatic Packaging Machine

The feed production line is designed to produce high quality feed particles. Generally used in industrial or commercial purposes, making feed particles and sells in the market. Compared with other feed particle making machines, this feed production line is more unique. The applied machine parts are more advanced. The control system is logical, which has better performance, thus ensuring high quality of the feed, competitive in the market.