Unlock The Secrets Of Efficientpowder nutritional supplement making machine Manufacturing

Importance of Automation in Modern Nutrition Production

In the dynamic landscape of the nutritional supplement industry, the significance of automation cannot be overstated. As consumer demand for high-quality, efficient, and sustainable production practices grows, the adoption of fully automated powder nutritional supplement making machines has become a cornerstone for modern nutrition production.

1.Automation streamlines the entire manufacturing process, enabling manufacturers to produce large quantities of nutritional supplements in a timely and cost-effective manner. Traditional methods of producing powder nutritional supplements often relied heavily on manual labor, which could lead to inconsistencies in product quality, increased labor costs, and potential health risks for workers. By contrast, fully automated machines eliminate these concerns by ensuring precision and accuracy in every stage of production, from raw material handling to final packaging.

2.Automation enhances product quality and consistency. With advanced control systems and sensors, fully automated powder nutritional supplement making machines can monitor and adjust production parameters in real-time, ensuring that every batch of supplements meets strict quality standards. This level of precision and control is simply not achievable with manual or semi-automated methods, making automation a vital tool for maintaining consumer trust and loyalty.

3.Automation promotes sustainability and eco-friendliness in nutrition production. By reducing waste, conserving energy, and minimizing the use of harmful chemicals, fully automated machines contribute to a greener, more sustainable future. This is particularly important in the context of the nutritional supplement industry, where consumer concerns about environmental impact are on the rise.

4.Automation allows manufacturers to respond quickly to market changes and consumer preferences. With the ability to adjust production schedules and recipes on the fly, automated machines ensure that businesses can stay agile and competitive in a rapidly evolving market.

In conclusion, the importance of automation in modern nutrition production cannot be understated. Fully automated powder nutritional supplement making machines offer numerous benefits, including increased efficiency, enhanced product quality, improved sustainability, and greater flexibility. As the industry continues to evolve, it is essential that manufacturers embrace automation as a key strategy for success and growth.

Understanding Fully Automated Powder Nutritional Supplement Making Machines

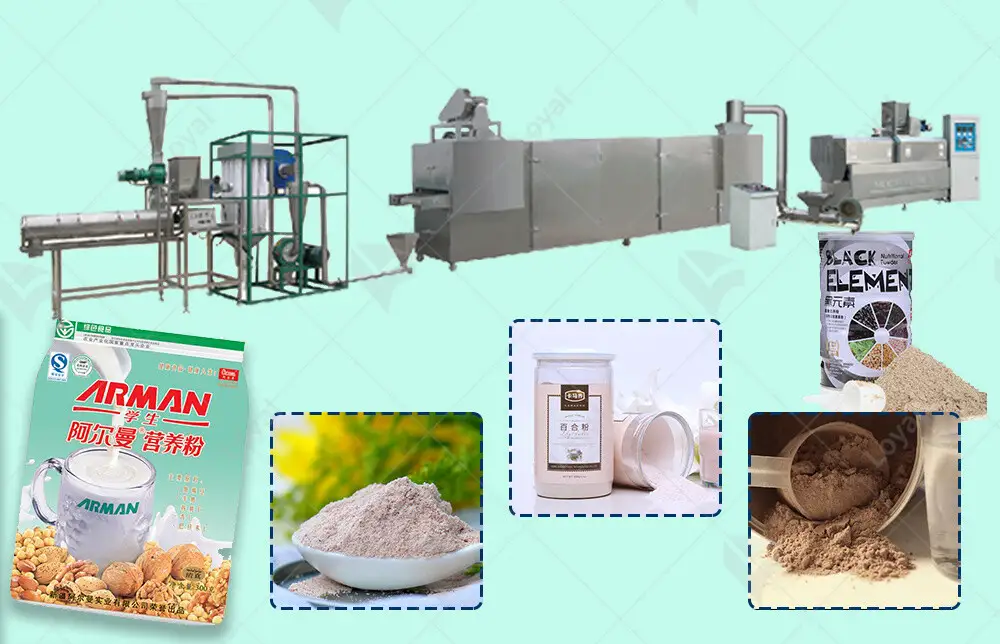

In the dynamic world of food manufacturing, the pursuit of efficiency and eco-friendliness has led to the rise of fully automated powder nutritional supplement making machines. These sophisticated systems represent a pivotal shift in the production of nutritional supplements, offering unparalleled precision, scalability, and environmental benefits. As an industrial food machinery expert, I'll delve into the intricacies of these machines, highlighting their key features and how they revolutionize the nutritional supplement industry.

Core Components and Functionality | At the heart of any fully automated powder nutritional supplement making machine lies a robust blending and drying system. These machines are designed to handle a wide range of raw materials, from vitamins and minerals to herbs and plant extracts, with ease. The blending process involves precision metering of each ingredient to ensure that the final product meets strict quality standards. Once blended, the mixture undergoes a drying process to convert it into a powder form. This is crucial for enhancing the product's stability, shelf life, and solubility. Fully automated machines utilize advanced drying technologies, such as spray drying or freeze drying, which preserve the nutritional integrity of the ingredients while achieving the desired powder consistency. |

Automation and Precision | One of the primary advantages of fully automated powder nutritional supplement making machines is their ability to automate virtually every step of the production process. From ingredient weighing and dispensing to mixing, drying, and packaging, these machines operate with minimal human intervention. This not only improves efficiency but also ensures a high degree of precision and consistency in the final product. Moreover, automation enables manufacturers to easily adjust production volumes based on market demand. With a few clicks on a control panel, they can ramp up or down production without compromising on quality or efficiency. |

Eco-Friendliness and Sustainability | In today's environmentally conscious world, eco-friendliness is a key consideration in the design and operation of food machinery. Fully automated powder nutritional supplement making machines are no exception. Many manufacturers have integrated energy-efficient technologies into their designs, such as variable-speed motors and heat recovery systems, to minimize energy consumption and reduce carbon emissions. Furthermore, these machines often feature advanced cleaning systems that ensure thorough sanitation after each production cycle. This not only maintains hygiene standards but also reduces the use of water and cleaning chemicals, further enhancing their eco-friendliness. |

Eco-Friendly Features of Modern Machines

In the realm of food machinery, the pursuit of eco-friendliness has gained significant momentum, particularly within the nutritional supplement industry. Modern fully automated powder nutritional supplement making machines have embraced this trend, incorporating innovative features that minimize environmental impact while maintaining exceptional production efficiency. As an industrial food machinery expert, I'll explore the eco-friendly attributes of these advanced machines and explain how they contribute to a more sustainable future.

Energy Efficiency at the Core | One of the most notable eco-friendly features of modern powder nutritional supplement making machines is their energy efficiency. Manufacturers have invested heavily in research and development to optimize the energy consumption of these systems. For instance, variable-speed motors are commonly used to adjust the power output precisely to the task at hand, reducing unnecessary energy waste. Additionally, heat recovery systems capture and reuse waste heat generated during the production process, further enhancing energy efficiency. |

Advanced Cleaning Technologies | Another eco-friendly aspect of these machines lies in their advanced cleaning technologies. Traditional cleaning methods often required large amounts of water and chemicals, which can have a significant environmental impact. However, modern powder nutritional supplement making machines utilize efficient cleaning systems that minimize water consumption and rely on eco-friendly cleaning agents. These systems ensure thorough sanitation after each production cycle, reducing the risk of contamination while safeguarding the environment. |

Reduced Waste Generation | One of the primary goals of eco-friendly machinery is to minimize waste generation. Modern powder nutritional supplement making machines achieve this through precise ingredient metering and mixing, which reduces the likelihood of over- or under-production. Furthermore, these machines often incorporate automated packaging systems that ensure accurate filling, minimizing packaging waste and enhancing product shelf life. |

Sustainable Material Choices | The materials used in the construction of modern powder nutritional supplement making machines also contribute to their eco-friendliness. Manufacturers are increasingly opting for sustainable materials, such as stainless steel and aluminum alloys, which are durable, recyclable, and have a lower environmental impact compared to traditional materials. Additionally, these materials are easy to clean and maintain, further reducing the need for chemicals and water during the cleaning process. |

Cost-Benefit Analysis of Automation

As an industrial food machinery expert, I often encounter businesses in the nutritional supplement industry weighing the pros and cons of automating their powder production processes. The decision to invest in fully automated powder nutritional supplement making machines is a strategic one that requires a thorough cost-benefit analysis. In this section, we'll delve into the key factors that contribute to the financial viability of automation, highlighting its potential to drive efficiency, reduce costs, and enhance profitability.

1.Increased Production Efficiency

One of the most compelling benefits of automation is its ability to significantly increase production efficiency. Fully automated powder nutritional supplement making machines operate with precision and consistency, eliminating human error and reducing downtime. This results in faster production cycles, higher output rates, and improved overall efficiency. In the long run, this increased efficiency translates into cost savings, as businesses can produce more products with fewer resources.

2.Reduced Labor Costs

Labor is often one of the largest expenses for manufacturers, particularly in labor-intensive industries like nutritional supplement production. Automation eliminates the need for manual labor in many stages of the production process, reducing labor costs and freeing up resources for other areas of the business. While the initial investment in automation may be substantial, the long-term savings in labor costs can be substantial, making automation a financially viable option for many businesses.

3.Improved Product Quality

Another significant benefit of automation is its ability to improve product quality. Fully automated powder nutritional supplement making machines ensure consistent ingredient metering, mixing, and packaging, resulting in products with uniform quality and fewer defects. This improved product quality can lead to increased customer satisfaction, repeat purchases, and positive word-of-mouth referrals, all of which contribute to the bottom line.

4.Reduced Waste and Material Costs

Automation also helps reduce waste and material costs. By precisely controlling ingredient metering and mixing, automated machines minimize over- or under-production, reducing waste and ensuring optimal material usage. Furthermore, advanced cleaning technologies minimize the need for water and chemicals, further reducing waste and costs associated with cleaning and disposal.

5.Scalability and Flexibility

As businesses grow, the need for scalability and flexibility becomes increasingly important. Fully automated powder nutritional supplement making machines are designed to accommodate varying production volumes and can be easily adapted to produce a wide range of products. This scalability and flexibility enable businesses to respond quickly to market demands, capitalize on new opportunities, and maintain a competitive edge.

Future Trends and Innovations in Automation

In the rapidly evolving world of food machinery, automation is not just a buzzword; it's a driving force behind the future of powder nutritional supplement production. As an industrial food machinery expert, I'm excited to share insights into the latest trends and innovations in automation that are reshaping the industry and pushing the boundaries of what's possible.

1. Advanced Robotics and AI Integration

One of the most significant trends in automation for powder nutritional supplement making machines is the integration of advanced robotics and artificial intelligence (AI). Robots are becoming increasingly sophisticated, capable of performing complex tasks with precision and speed. AI algorithms, on the other hand, enable machines to learn and adapt, optimizing production processes in real-time. This combination of robotics and AI is transforming powder nutritional supplement production, enabling manufacturers to achieve unprecedented levels of efficiency, flexibility, and quality control.

2. Internet of Things (IoT) Connectivity

The Internet of Things (IoT) is another key trend driving innovation in automation. By connecting powder nutritional supplement making machines to the internet, manufacturers can monitor and control production processes remotely, in real-time. This IoT connectivity enables predictive maintenance, reducing downtime and improving overall equipment effectiveness. Additionally, IoT-enabled machines can collect and analyze vast amounts of data, providing valuable insights into production processes and enabling manufacturers to make data-driven decisions that optimize performance and reduce costs.

3. Sustainable and Eco-Friendly Automation

As consumer awareness of sustainability grows, so too does the demand for eco-friendly production processes. The future of automation in powder nutritional supplement making machines will increasingly prioritize sustainability. This includes the development of energy-efficient machines, the use of recyclable materials in machine construction, and the implementation of waste reduction strategies. Manufacturers are also exploring ways to automate recycling and repurposing processes, turning waste into valuable resources.

4. Personalization and Customization

In today's consumer-driven market, personalization and customization are becoming increasingly important. Automation is enabling powder nutritional supplement manufacturers to offer a wider range of products tailored to individual needs and preferences. Advanced automation technologies, such as flexible packaging systems and on-demand ingredient blending, are making it possible to produce small batches of customized products quickly and efficiently.

5. Smart Factories and Digital Transformation

The concept of smart factories is gaining traction in the food machinery industry, and powder nutritional supplement production is no exception. Smart factories leverage advanced automation technologies, IoT connectivity, and AI algorithms to create highly integrated and intelligent production environments. This digital transformation is enabling manufacturers to streamline processes, reduce waste, and improve overall performance. As smart factories become more prevalent, powder nutritional supplement production will become even more efficient, sustainable, and responsive to market demands.

In conclusion, the future of automation in powder nutritional supplement making machines is bright and full of exciting possibilities. From advanced robotics and AI integration to sustainable and eco-friendly automation, personalization and customization, and smart factories, the industry is poised for significant growth and innovation. As an industrial food machinery expert, I encourage manufacturers to stay abreast of these trends and embrace automation as a strategic investment in their future success.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/