The Ultimate Guide to Corn Flakes Production Machine in 2024

The Importance of Corn Flakes Production Equipment in the Food Industry

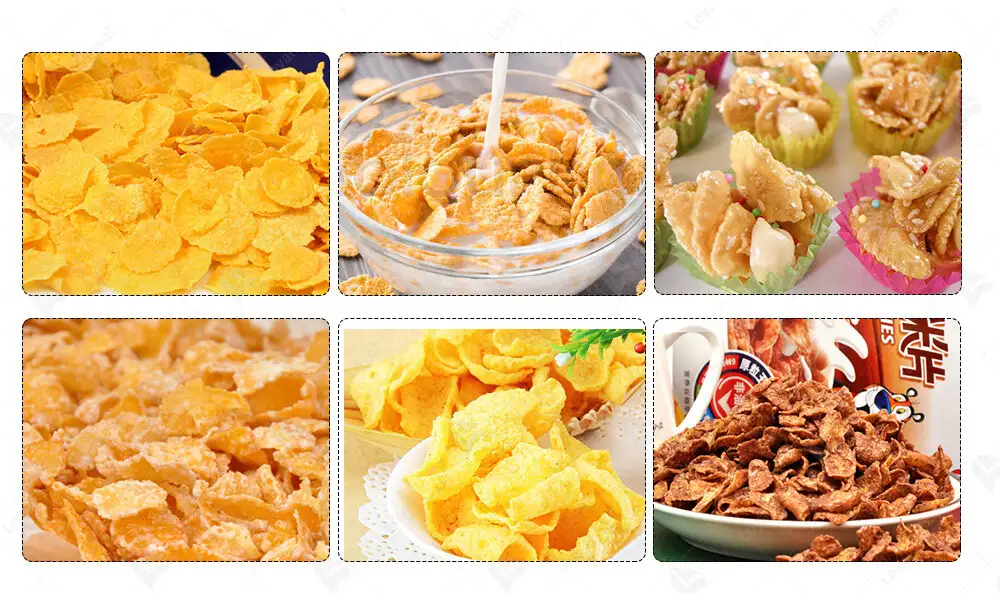

In the bustling landscape of the food industry, the role of corn flakes production equipment corn flakes production machine stands as a cornerstone of efficiency and innovation. These machines play a pivotal role in the mass production of one of the world's most beloved breakfast cereals, catering to the insatiable appetite of consumers worldwide.

Corn flakes production machines are more than just mere pieces of equipment; they represent the culmination of decades of technological advancements and culinary expertise. With their precise engineering and automated functionalities, these machines streamline the entire production process, from raw material input to the packaging of the final product.

In today's fast-paced world, where consumer demands are ever-evolving and competition is fierce, the importance of corn flakes production equipment cannot be overstated. These machines empower manufacturers to meet the escalating demand for corn flakes efficiently, ensuring a steady supply of this breakfast staple to households, eateries, and markets globally.

Furthermore, corn flakes production machines uphold the highest standards of product quality and consistency. Through meticulous control of variables such as temperature, pressure, and ingredient proportioning, these machines produce corn flakes of unparalleled uniformity and taste, winning the trust and loyalty of consumers.

The importance of efficient and advanced machinery for the production of high-quality corn flakes.

In the realm of industrial food processing, the corn flakes production machine stands as a cornerstone of efficiency and innovation. As we delve into the importance of efficient and advanced machinery for the production of high-quality corn flakes, it becomes evident that these specialized production lines play a pivotal role in meeting consumer demand while maintaining standards of excellence.

Efficiency and Precision

At the heart of every successful corn flakes production operation lies a meticulously engineered corn flakes production machine. These state-of-the-art systems are designed to streamline the manufacturing process from start to finish, ensuring maximum efficiency at every stage. From the precise handling of raw materials to the controlled extrusion and shaping of the flakes, every aspect of the production line is optimized for speed, accuracy, and consistency.

Quality Assurance

In the competitive landscape of the food industry, quality is paramount. The use of advanced machinery in corn flakes production not only enhances efficiency but also guarantees the highest standards of quality and safety. By incorporating cutting-edge technology and stringent quality control measures, manufacturers can produce corn flakes that are not only delicious but also free from impurities and defects.

Meeting Consumer Demand

With the global demand for corn flakes on the rise, manufacturers are under increasing pressure to ramp up production while maintaining product integrity. The adoption of advanced machinery allows companies to scale their operations without compromising on quality or consistency. Whether catering to domestic markets or fulfilling international orders, a robust corn flakes production machine is essential for meeting the ever-growing needs of consumers worldwide.

Work flow of corn flakes production machine

Preparation of Ingredients: Corn flour is the main ingredient for making breakfast corn flakes. In this step, ensure that the quality of the corn flour meets the production requirements, and prepare other auxiliary materials and additives, such as water, salt, sugar, etc.

Mixing and Stirring: Mix the corn flour with water, salt, and other auxiliary ingredients, and stir to ensure that all ingredients are evenly mixed.

Extrusion Molding: The gelatinized corn mixture is molded through an extruder or extrusion roller. Specific molds or templates are usually used to extrude the corn mixture into the desired shapes, such as square or round corn flakes.

Drying: The molded corn flakes are sent to a drying chamber or oven to remove moisture, making the corn flakes crispy. The temperature and time of drying are controlled according to the product requirements.

Cooling and Packaging: The finished corn flakes need to be cooled after baking or frying to lower the temperature and solidify. They are then sent to the packaging line for packaging, usually using food-grade plastic bags or packaging boxes, and sealed and labeled.

Quality Control: Quality control is conducted throughout the entire production process, including inspection of raw materials, production environment, various steps in the production process, and the quality of the final product, to ensure that the product meets relevant hygiene, safety, and quality standards.

The above is the typical industrial process for making breakfast instant corn flakes. The specific production process may vary depending on the manufacturer's equipment, techniques, and product formulations.

Advantages of corn flakes production machine

Advantages | Description |

Efficiency | Corn flakes production machines are highly efficient, capable of processing large quantities of corn rapidly. |

Consistency | These machines ensure uniformity in the size, shape, and texture of corn flakes, maintaining product quality. |

Cost-effectiveness | By automating the production process, corn flakes production machines reduce labor costs and minimize waste. |

Customization | Manufacturers can adjust parameters to meet specific product requirements, offering versatility in production. |

High Output | With optimized workflows and high-speed processing, these machines yield substantial outputs to meet market demand. |

Quality Assurance | Advanced monitoring systems ensure adherence to stringent quality standards, enhancing consumer satisfaction. |

Longevity and Reliability | Corn flakes production machines are built to withstand rigorous operation, ensuring prolonged service life. |

Streamlined Operations | The integrated design of these machines streamlines production workflows, minimizing downtime and maximizing productivity. |

Technology Integration | Incorporation of cutting-edge technologies enhances efficiency and precision in every stage of production. |

Market Competitiveness | By improving efficiency and product quality, corn flakes production machines empower manufacturers to remain competitive. |

Advanced Corn Flakes Production Technology

In the landscape of industrial food machinery, corn flakes production machines stand out as exemplars of technological advancement. In 2024, these machines have undergone significant evolution, integrating cutting-edge features and innovations to enhance efficiency and product quality.

Integrated Automation Systems

One of the hallmarks of advanced corn flakes production machines is their integration of sophisticated automation systems. These systems orchestrate the entire production process with unparalleled precision and efficiency. From the initial cleaning and conditioning of raw maize to the final packaging of crispy corn flakes, every stage is seamlessly synchronized, minimizing human intervention and maximizing throughput.

Precision Extrusion Technology

At the heart of modern corn flakes production machines lies precision extrusion technology. This innovative process involves subjecting the prepared maize to carefully controlled temperature and pressure conditions, resulting in the formation of a homogeneous dough-like mixture. By precisely regulating these parameters, manufacturers can achieve consistency in texture and flavor, producing corn flakes of exceptional quality and uniformity.

Advanced Shaping and Cutting Mechanisms

The shaping and cutting mechanisms of contemporary corn flakes production machines have been refined to perfection. High-precision rollers impart the distinctive elongated shape to the dough, while state-of-the-art cutting blades ensure precise segmentation into individual flakes. This level of precision not only enhances the visual appeal of the final product but also facilitates efficient packaging and distribution.

Innovative Toasting and Drying Techniques

To impart the characteristic crispiness and flavor to corn flakes, advanced production machines employ innovative toasting and drying techniques. Through precise control of temperature and airflow within dedicated toasting chambers, manufacturers can achieve optimal browning and flavor development while simultaneously removing excess moisture. The result is a batch of perfectly toasted corn flakes with a delectable crunch and rich aroma.

Operation Precautions

Operating a corn flakes production machine demands meticulous attention to detail and adherence to safety protocols to ensure smooth functioning and prevent accidents. Here are some crucial operation precautions to consider:

1. Equipment Inspection: Before commencing operation, thoroughly inspect the corn flakes production machine for any signs of wear, damage, or malfunction. Pay particular attention to moving parts, electrical components, and safety guards.

2. Proper Training: Ensure that operators receive comprehensive training on the operation and maintenance of the corn flakes production machine. Familiarize them with safety procedures, emergency shutdown protocols, and the correct use of protective equipment.

3. Control Settings: Strictly adhere to recommended control settings for temperature, pressure, and processing speed. Deviating from these parameters can compromise product quality and pose safety risks.

4. Material Handling: Exercise caution when handling raw materials, especially during loading and unloading procedures. Follow proper lifting techniques to prevent strain injuries, and use appropriate equipment such as forklifts or conveyors for heavy loads.

5. Emergency Preparedness: Equip the production facility with emergency stop buttons, fire extinguishers, and first-aid kits in accessible locations. Conduct regular drills to ensure that operators are proficient in responding to emergencies promptly and effectively.

6. Maintenance Schedule: Implement a proactive maintenance schedule to keep the corn flakes production machine in optimal condition. Regularly inspect and lubricate moving parts, replace worn-out components, and calibrate sensors and control systems as necessary.

7. Cleanliness and Hygiene: Maintain strict cleanliness and hygiene standards throughout the production process to prevent contamination and ensure product safety. Regularly sanitize equipment surfaces, conveyor belts, and processing chambers to eliminate bacterial growth and foreign particles.

8. Supervision and Monitoring: Assign dedicated personnel to oversee the operation of the corn flakes production machine and monitor performance indicators such as production yield, energy consumption, and equipment efficiency. Promptly address any deviations from established norms to prevent downtime and minimize losses.

By adhering to these operation precautions, manufacturers can maximize the productivity, efficiency, and safety of their corn flakes production machine, ensuring consistent quality and meeting the demands of consumers in the competitive food industry landscape of 2024.

Comparison between loyal and axor companies

Aspect | Loyal | Axor |

Product Range | Specializes in manufacturing a wide range of industrial food machinery, including mixers, extruders, ovens, and packaging equipment. | Focuses primarily on the production of precision cutting and slicing machinery tailored for the food processing industry. |

Market Presence | Established global presence with distribution networks spanning multiple continents. | Predominantly serves European and North American markets with limited penetration in other regions. |

Innovation | Known for innovative technologies, regularly introducing new features and advancements to enhance efficiency and product quality. | Emphasizes traditional craftsmanship combined with modern engineering principles, resulting in reliable, time-tested machinery designs. |

Customization | Offers extensive customization options to tailor machinery according to specific client requirements, including size, capacity, and functionality. | Provides limited customization options, with a focus on standardized machine models optimized for general industry use. |

Customer Support | Provides comprehensive after-sales support, including technical assistance, spare parts availability, and maintenance services, ensuring uninterrupted operation of machinery. | Offers responsive customer support but may face challenges with spare parts availability and technical assistance in certain regions. |

Reputation | Highly regarded in the industry for consistent product quality, reliability, and customer satisfaction. | Holds a strong reputation for precision engineering and durable machinery but may lack the versatility of its competitors. |

Price | Generally positioned in the mid to high-end price range, reflecting the quality and performance of its machinery. | Offers competitive pricing, making it an attractive option for budget-conscious buyers without compromising on quality. |

Sustainability | Actively invests in sustainable manufacturing practices and energy-efficient technologies, aligning with industry trends and environmental regulations. | Incorporates eco-friendly materials and energy-saving features where feasible but may prioritize other aspects of product design and performance. |

Trends and Future Prospects

In recent years, the corn flakes production machine industry has witnessed several notable trends that are shaping its trajectory and future prospects.

Integration of AI and Automation: As technology continues to advance, we can expect to see greater integration of artificial intelligence (AI) and automation into corn flakes production machines. These advancements enable real-time monitoring, predictive maintenance, and adaptive control systems, enhancing operational efficiency and product quality.

Sustainability and Environmental Considerations: With increasing consumer awareness and regulatory pressures, sustainability has become a paramount concern for manufacturers. In response, corn flakes production machines are being designed with eco-friendly features such as energy-efficient components, waste reduction mechanisms, and recyclable materials. This trend is not only driven by ethical considerations but also by the potential for cost savings and market differentiation.

Customization and Flexibility: Consumer preferences are becoming increasingly diverse, driving demand for personalized and niche products. To meet this demand, corn flakes production machines are being equipped with modular designs and versatile capabilities, allowing manufacturers to easily adjust recipes, shapes, and flavors. This trend towards customization not only caters to evolving consumer tastes but also fosters innovation and competitiveness within the industry.

Global Market Expansion: As emerging markets continue to develop and urbanize, the demand for convenience foods like corn flakes is on the rise. Consequently, manufacturers are expanding their presence in regions such as Asia-Pacific, Latin America, and Africa. This expansion entails localization of production facilities and customization of machines to suit local ingredients and preferences. Furthermore, advancements in logistics and distribution networks are facilitating seamless access to these markets, driving further growth and opportunities for the industry.

As we look to the future of corn flakes production machines, it is evident that innovation, sustainability, and adaptability will be the driving forces shaping this dynamic industry. By embracing these trends and leveraging technological advancements, manufacturers can position themselves for success in an increasingly competitive and evolving market landscape.

Reference materials

Here are some authoritative foreign websites for industrial food machinery-related literature references, along with their URLs:

1. Food Engineering Magazine

Website: [https://www.foodengineeringmag.com/]

2. Food Processing Magazine

Website: [https://www.foodprocessing.com/]

3. Institute of Food Technologists (IFT)

Website: [https://www.ift.org/]

4. American Society of Agricultural and Biological Engineers (ASABE)

Website: [https://www.asabe.org/]

5. European Federation of Food Science and Technology (EFFoST)

Website: [https://effost.org/]

These websites provide a wide range of information related to industrial food machinery, including the latest industry news, research findings, and technological trends, making them valuable resources for authoritative references and academic research.